Method and grinding machine for grinding workpieces with grooves

A grinding machine and grinding technology, applied in the direction of grinding machine tool parts, workpiece feed movement control, grinding/polishing equipment, etc., can solve problems such as positioning errors and contour setting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

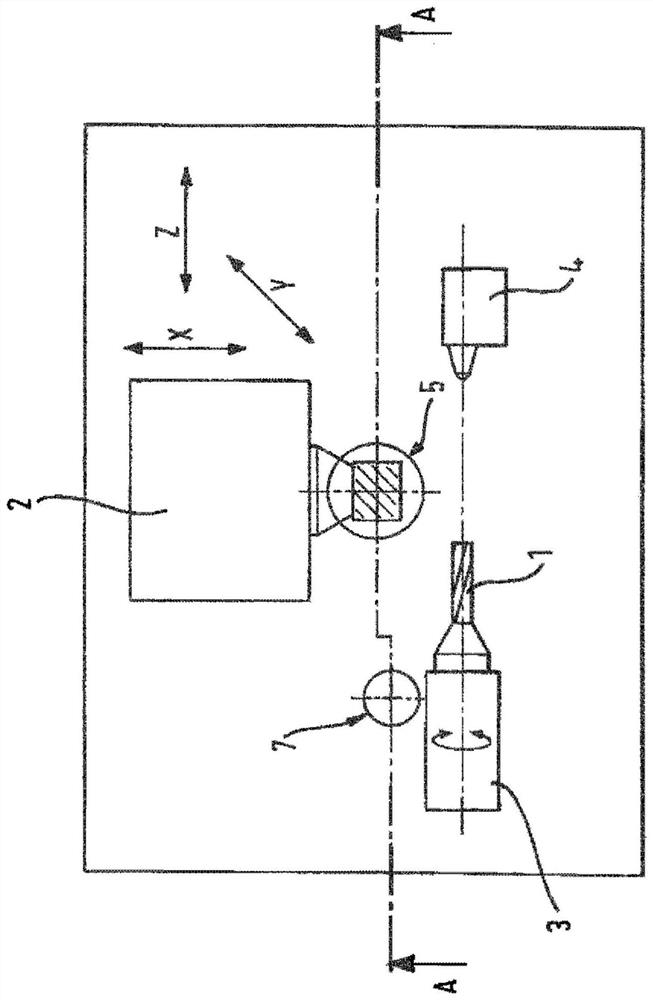

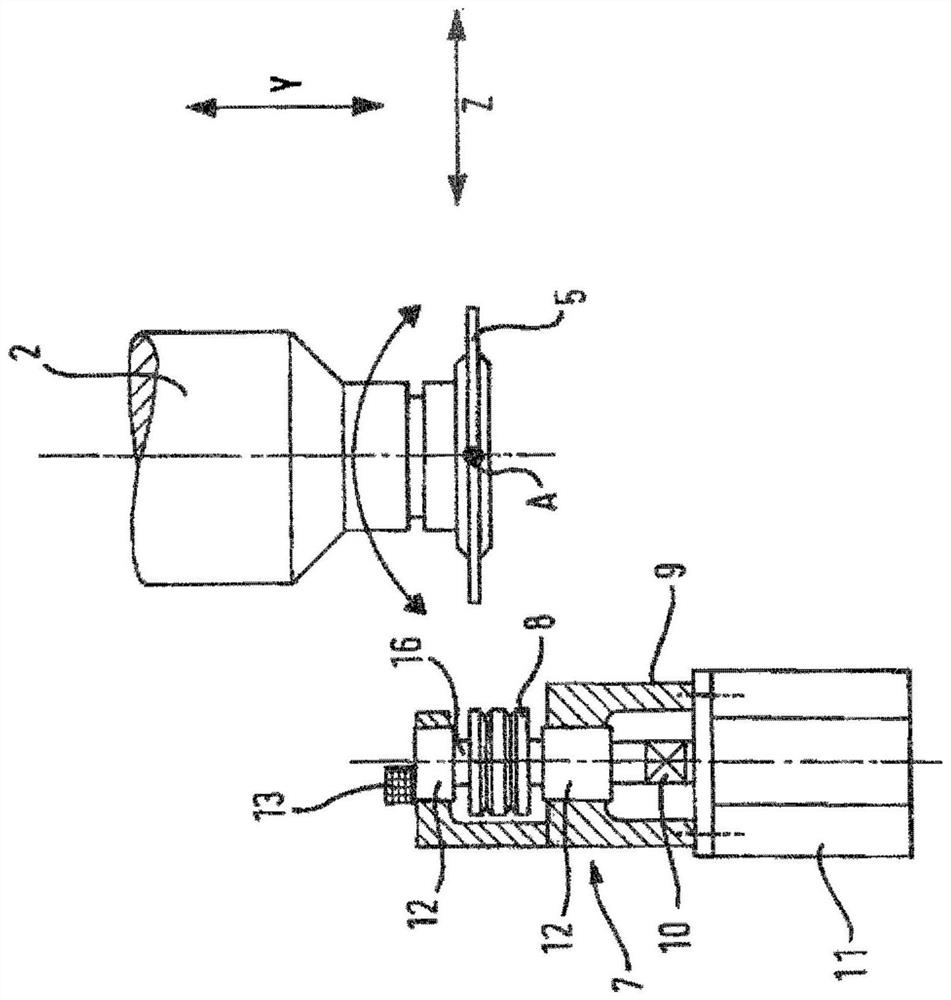

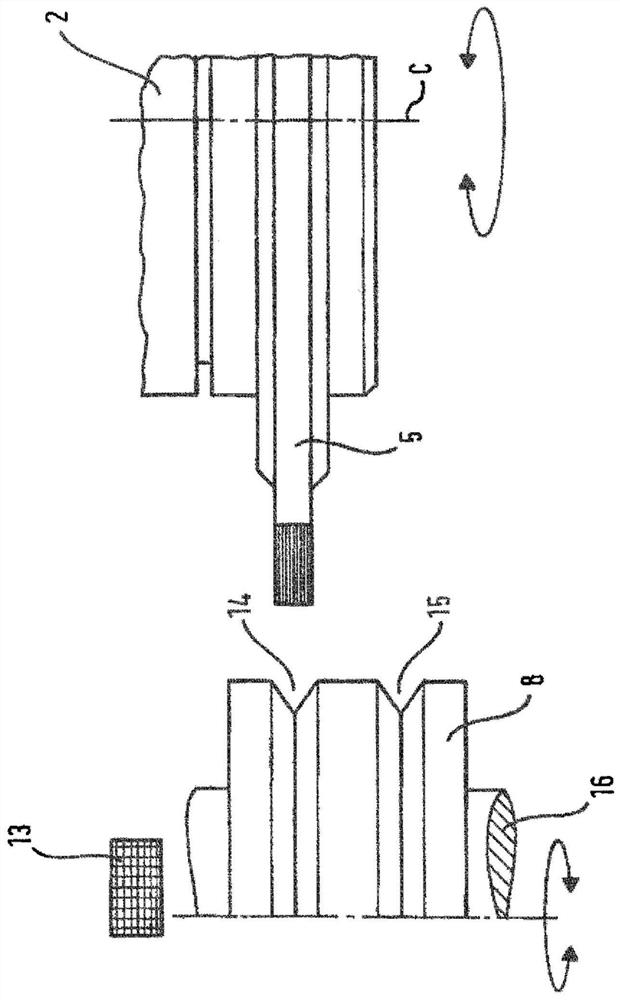

[0047] exist figure 1 The arrangement of the main components of the grinding machine according to the invention on the machine tool is shown in a schematic diagram in top view. A workpiece spindle seat with a workpiece spindle with a C-axis clamps the workpiece 1 . In order to optionally clamp the workpiece on the center, a displaceable tailstock 4 with the center is arranged in the extension of the longitudinal axis of the workpiece mandrel. A grinding mandrel seat with a grinding mandrel is arranged on the cross slide arranged on the machine tool, and the grinding disc 5 is arranged on the grinding mandrel. The grinding disc 5 has a set contour with which the corresponding groove is ground into the workpiece 1 . For this purpose, the grinding disc can be moved by means of the CNC axes in the X-direction, Z-direction and Y-direction and can be fed towards the workpiece 1 . In addition, a lamination device 7 is provided, which carries lamination rollers. In any case, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com