A three-dimensional storage device for glass magnesium boards and storage method thereof

A glass magnesium board and storage technology, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of lower production efficiency, heavy weight, and large floor space, so as to improve the application range, small civil engineering, and occupy a large area. The effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

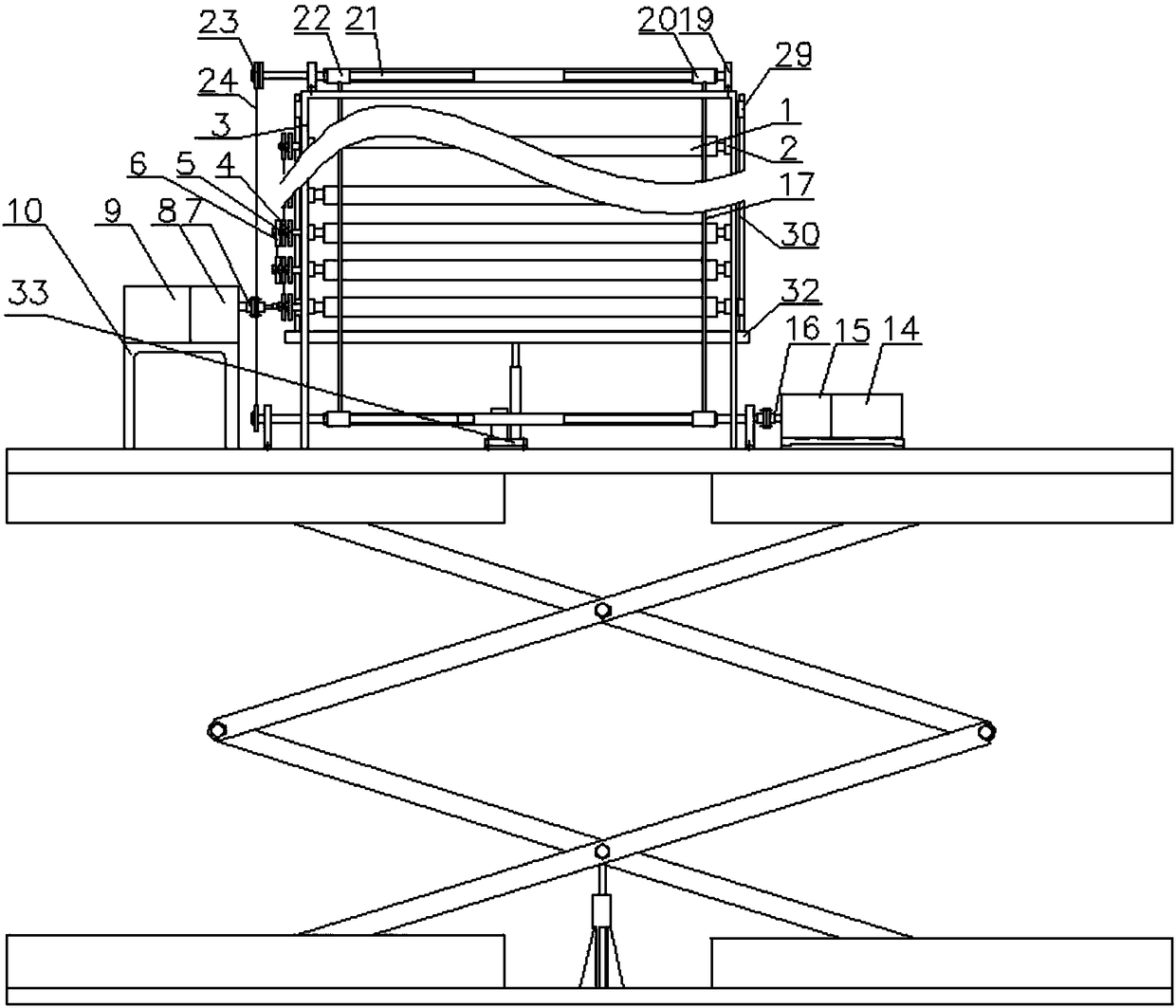

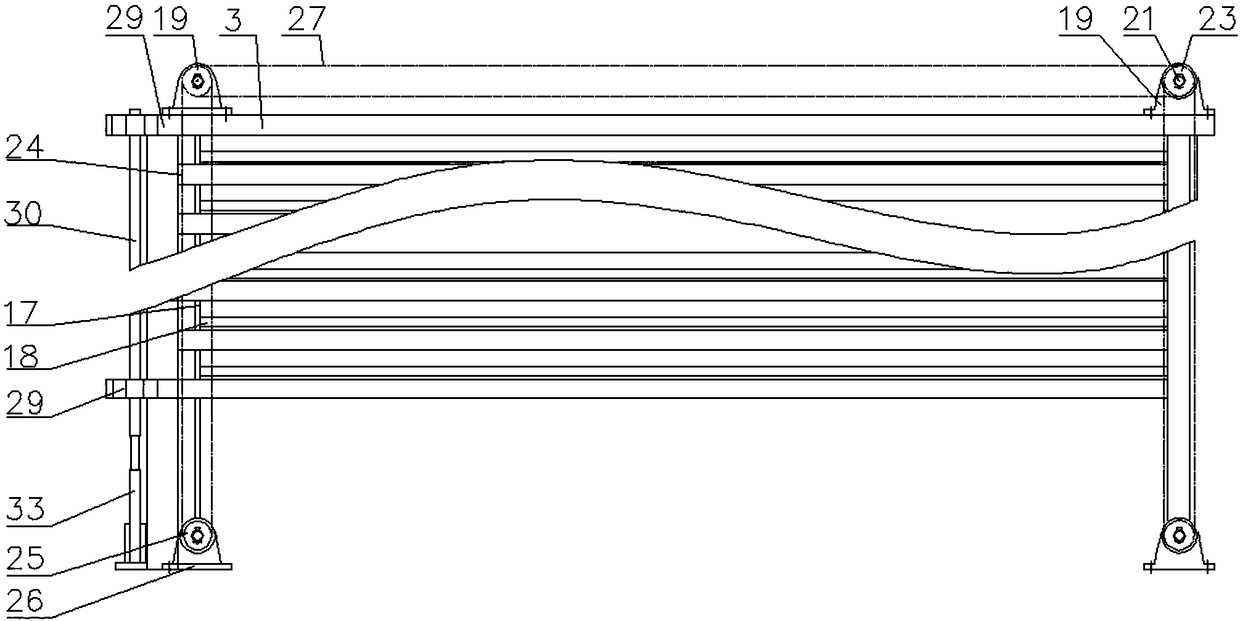

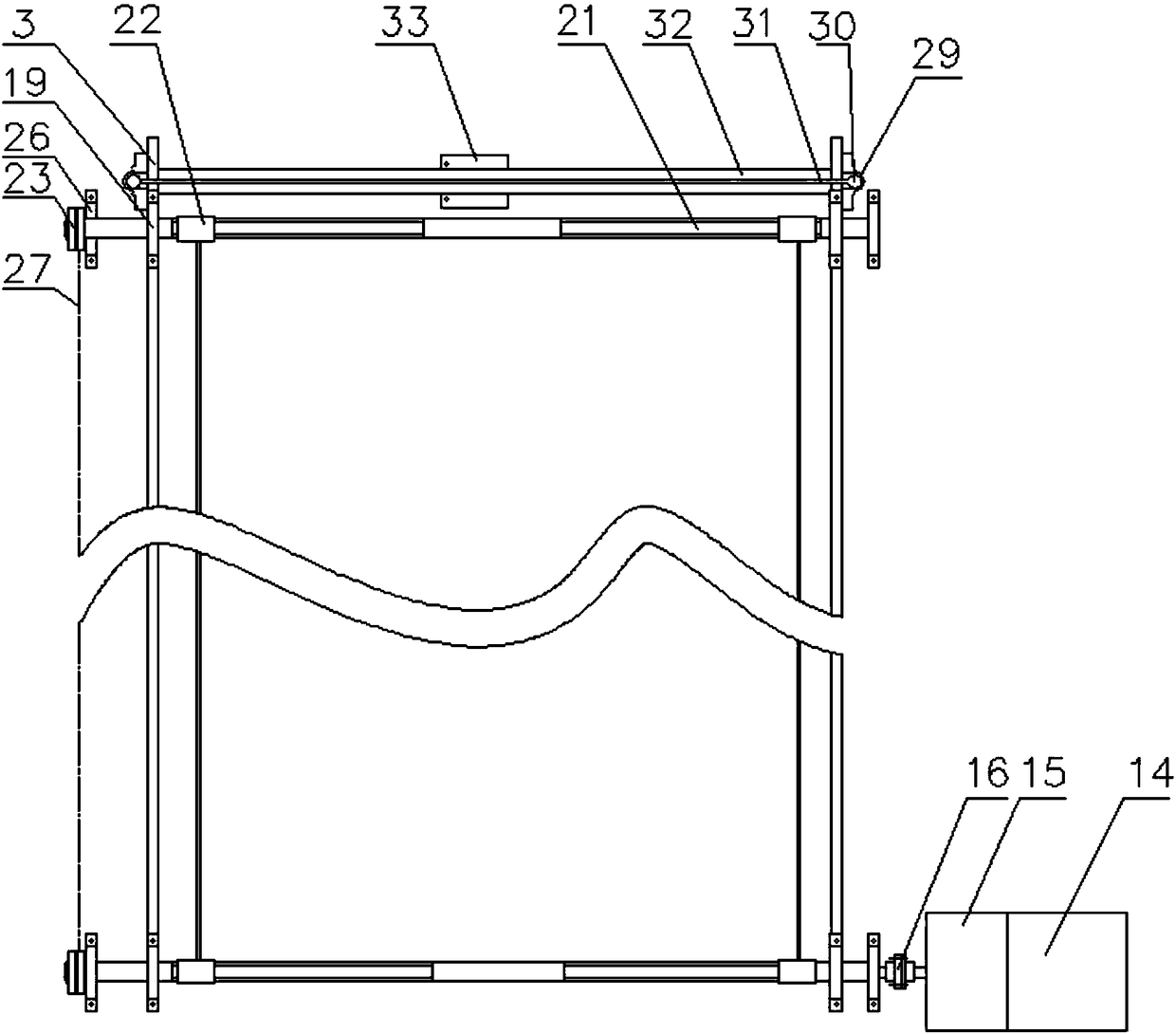

[0043] Such as Figure 1 to Figure 3 As shown, the rolling three-dimensional storage device for glass magnesium plates includes a three-dimensional shelf assembly for storing glass magnesium plates, and adjusts the width to adapt to guide components for glass magnesium plates of different width specifications, preventing glass magnesium plates from rushing out of the shelf due to inertia after entering the three-dimensional shelf The crosspiece assembly, and the lifting platform assembly that moves the above mechanism up and down so that the glass magnesium board can be smoothly fed into the three-dimensional shelf.

[0044] Such as Figure 4 , Figure 6 As shown, the three-dimensional shelf assembly for placing glass magnesium plates includes roller 1, bearing with sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com