Uniform rolling equipment

A kind of equipment and uniform technology, applied in the field of uniform rolling equipment, can solve the problems of unsatisfactory rolling effect, large pieces slipping off the user, and prone to figure-eight shapes, etc., to achieve good rolling effect, improve aesthetics, and reduce equipment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

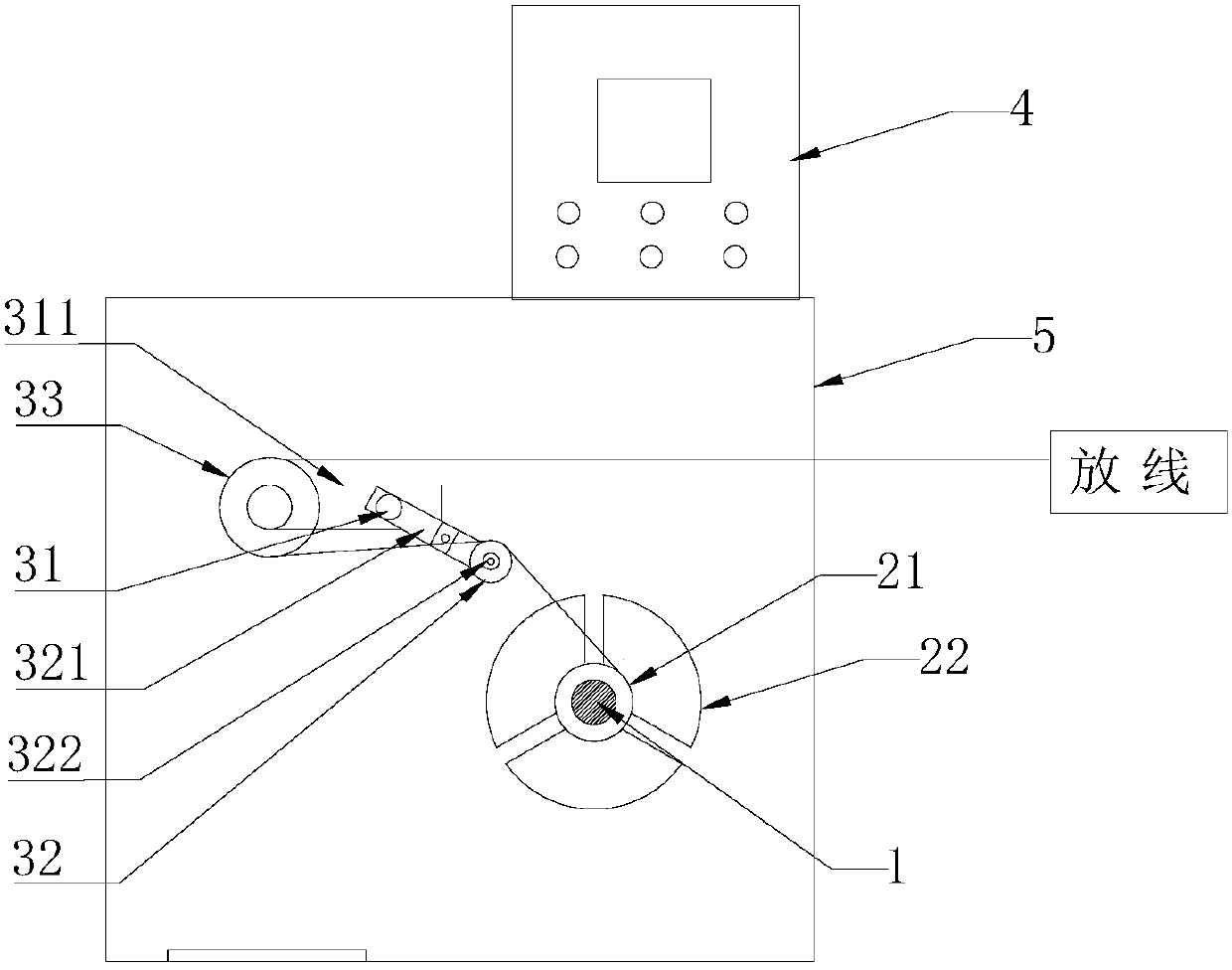

[0026] This embodiment provides a kind of uniform rolling equipment, such as figure 1 As shown, it includes: frame 5, guide wheel 1 (shown in the figure is a schematic representation of the guide wheel shaft, the actual situation cannot see the guide wheel from the front), a coiling mechanism, and a cable control mechanism;

[0027] The guide wheel 1 is driven to rotate by a motor, and the guide wheel 1 is fixed on the frame 5;

[0028] The coiling mechanism includes a mandrel 21 and a coiling disc 22. The guide wheel 1 drives the mandrel 21 to rotate. The coiling disc 22 is detachably sleeved on the mandrel 21. The mandrel 21 is provided with a limiter for limiting the coiling disc. device (not shown in the figure);

[0029] The cable arrangement control mechanism includes a cable arrangement 31 (shown as the bearing of the cable arrangement) and a line position wheel 32. The cable arrangement 31 is fixed on the frame 5, and the cable arrangement 31 is driven by a servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com