Equipment used for rolling cones

A technology of cones and equipment, applied in applications, household appliances, and other household appliances, can solve the problems of large roundness tolerance, long-term crane occupancy, and low work efficiency, so as to reduce occupation time, ensure molding accuracy, and reduce processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

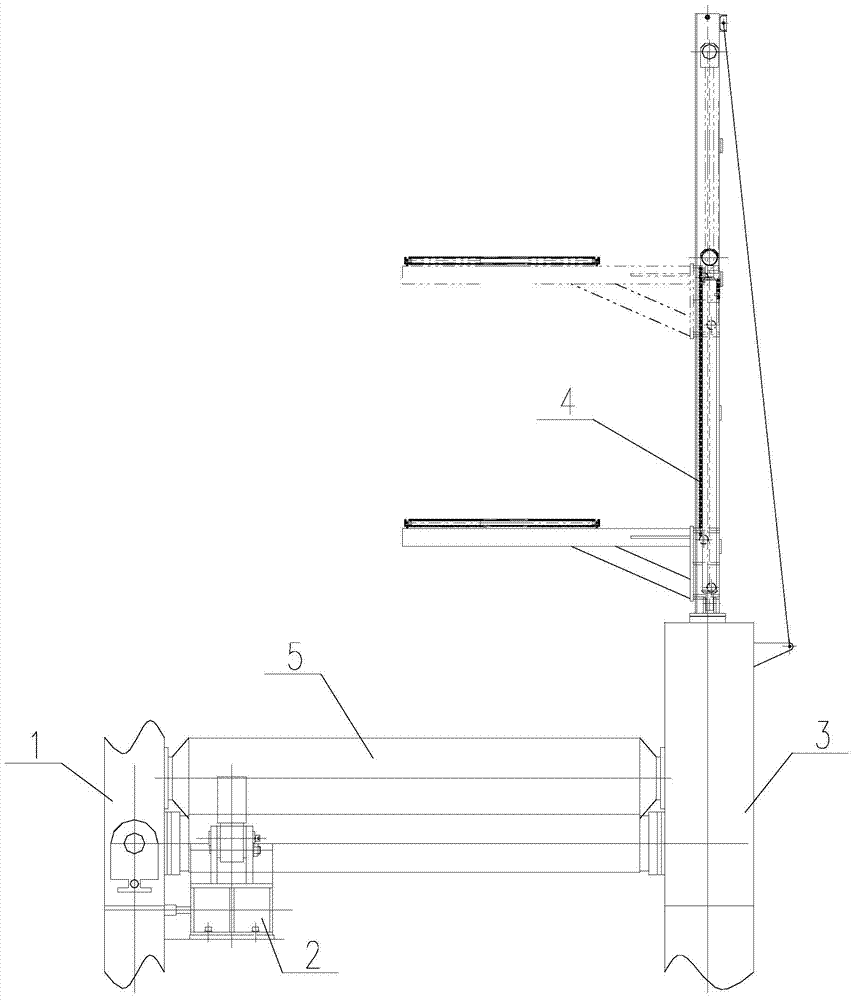

[0018] see Figure 1 to Figure 6 , a kind of equipment for rolling cones, including a plate rolling machine, the two ends of the plate rolling machine are respectively an overturning frame 1 and a fixed frame 3, and a coil is installed inside the overturning frame 1 Cone Tooling 2.

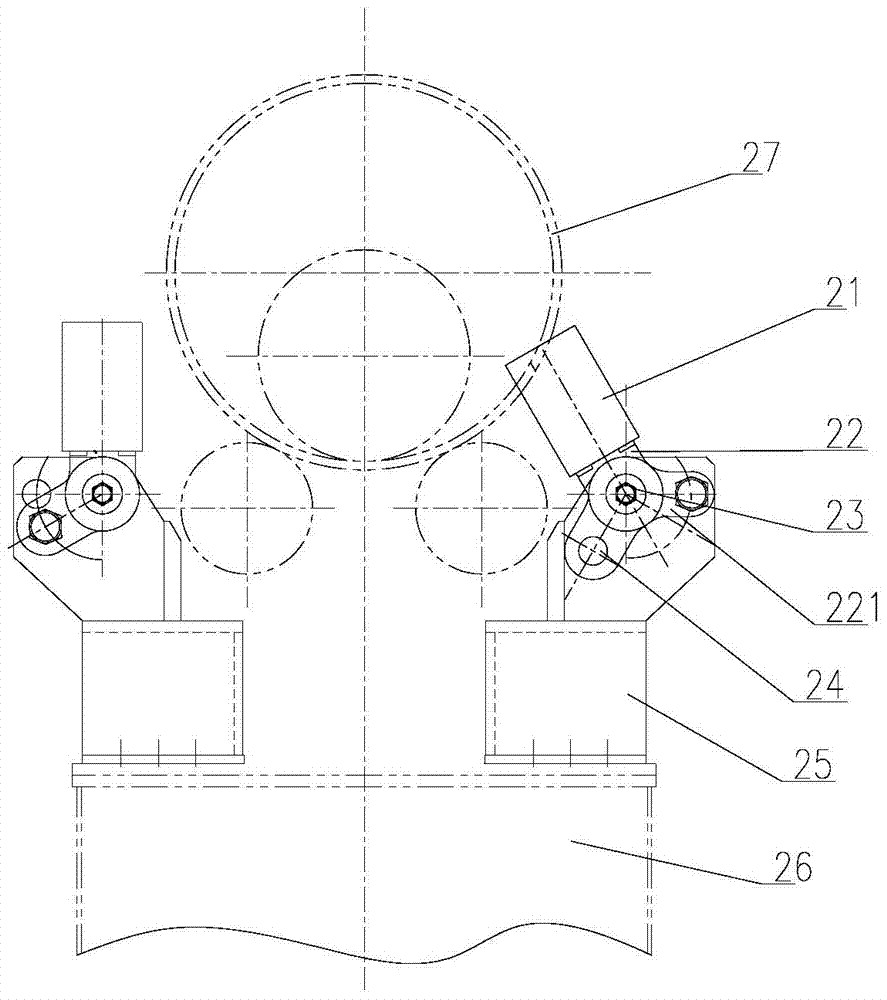

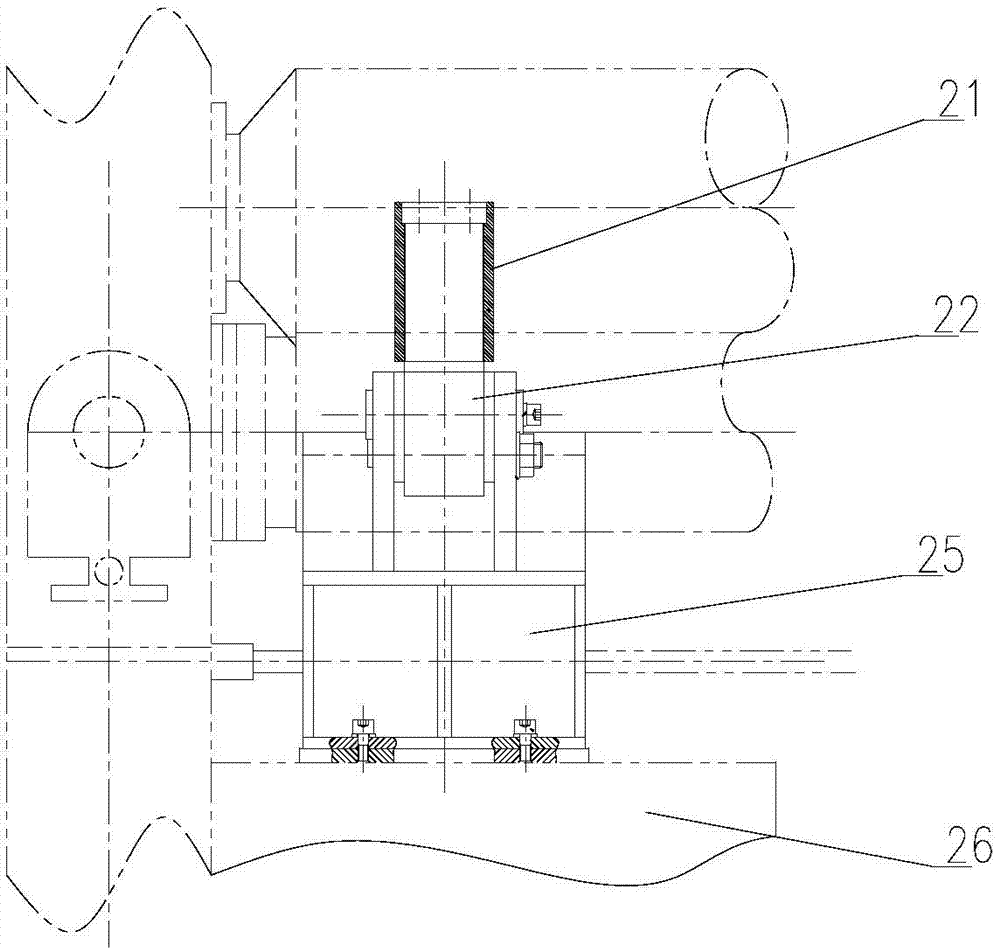

[0019] The above-mentioned cone rolling tool 2 includes a bracket 26, on which two sets of friction limiting devices are arranged, and the structures of the two sets of friction limiting devices are axisymmetrically arranged. The vertical line at the center of the cross-section; each set of friction limiting devices includes a support 25, a pin shaft 23, a hinge shaft 22 and a roller sleeve 21 fixedly connected to the bracket 26; the upper part of the hinge shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com