Equipment for winding paper cups into cylinders

A technology of forming a tube and equipment, which is applied in the manufacture of papermaking, paper/cardboard containers, rigid/semi-rigid containers, etc., and can solve the problems of unfavorable mass production and slow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

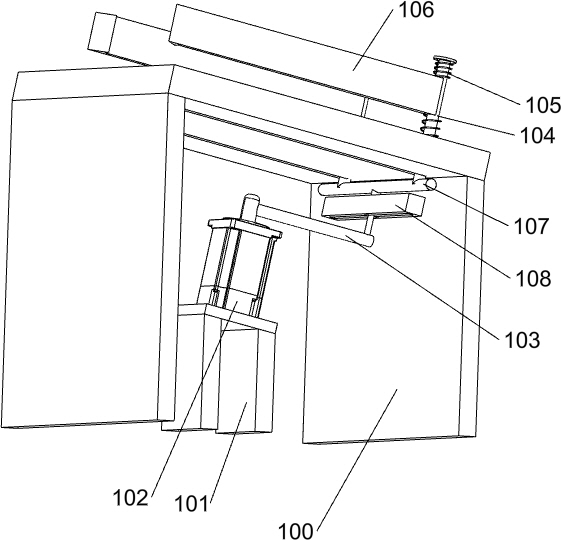

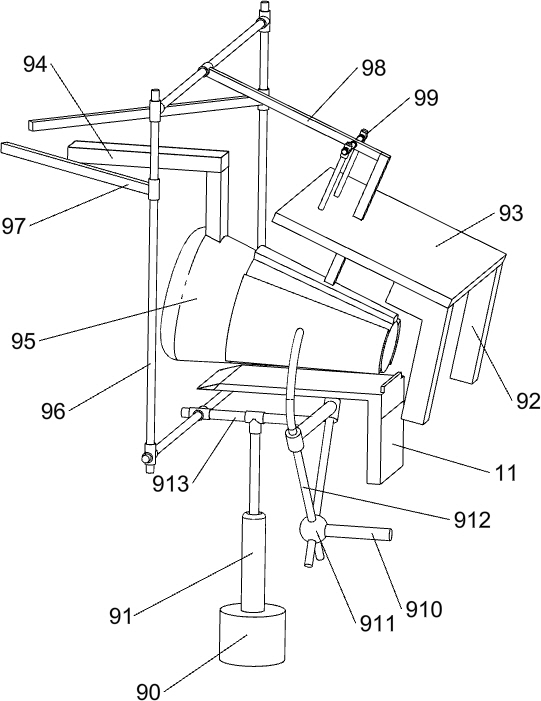

[0021] A device that rolls paper cups into cylinders, such as Figure 1-4 As shown, it includes a bottom plate 1, a support frame 2, a connecting plate 3, a first support member 4, a first servo motor 5, a bearing seat 6, a rotating shaft 7, a conveyor belt 8, a roll forming mechanism 9, a blanking mechanism 10, a placement Platform 11 and pulley assembly 12, two groups of support frames 2 are arranged symmetrically front and back on the left side of the upper part of the bottom plate 1, connecting plates 3 are arranged on the two groups of support frames 2, and the first support member 4 is arranged on the left rear side of the upper part of the bottom plate 1, and the second A first servo motor 5 is arranged on the upper part of a support member 4, and a bearing seat 6 is provided symmetrically front and back in the left side of the upper part of the base plate 1 and in the middle of the upper part of the base plate 1, and a rotating shaft 7 is arranged between the bearing se...

Embodiment 2

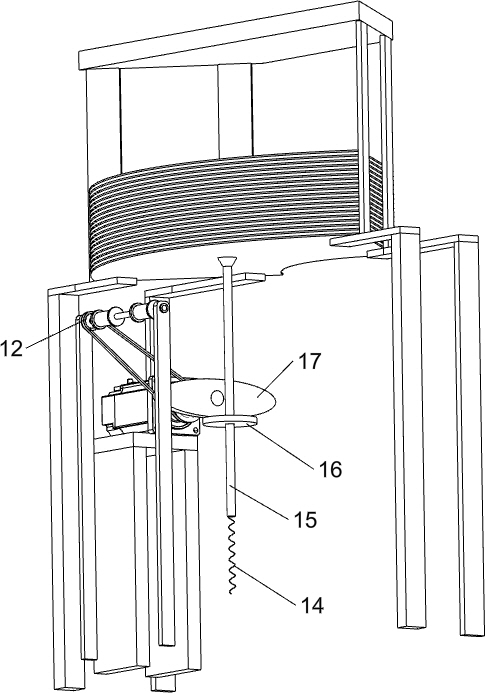

[0028] On the basis of Example 1, such as figure 1 and Figure 4 As shown, it also includes a fixed sleeve 13, a return spring 14, a lifting suction cup 15, a fixed disc 16 and a cam 17. The left side of the upper part of the bottom plate 1 is provided with a fixed sleeve 13, and the fixed sleeve 13 is located in front of the first support member 4. side, the fixed sleeve 13 is provided with a return spring 14, and the fixed sleeve 13 is slidingly provided with a lifting suction cup 15, the bottom of the lifting suction cup 15 is connected with the return spring 14, and the upper part of the lifting suction cup 15 is provided with a fixed disc 16, the first servo The output shaft of the motor 5 is provided with a cam 17, and the cam 17 cooperates with the fixed disk 16.

[0029] After the cardboard that needs to be rolled into a tube is placed on the support frame 2, the lifting suction cup 15 will contact the bottom cardboard, and the rotation of the first servo motor 5 will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com