Ceramic rolling and pressing machine

A technology of rolling machine and ceramics, which is applied in the direction of ceramic forming machines, forming indenters, manufacturing tools, etc., and can solve the problems of horizontal forward and backward movement, low production efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

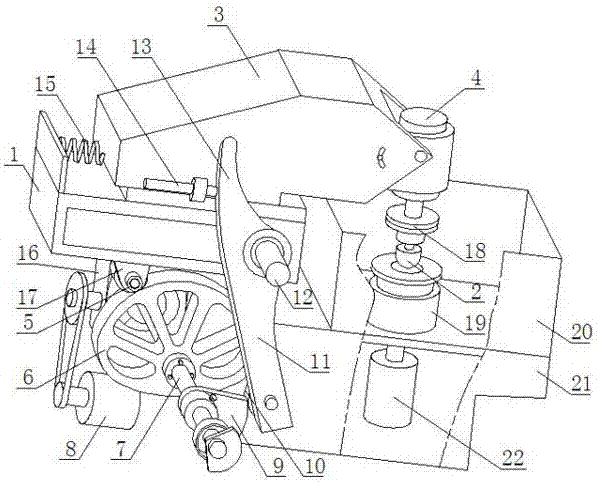

[0018] refer to figure 1 , the ceramic rolling machine comprises a body 21, a frame 1, a rolling head 2 and a rolling die 19, the rear of the body 21 is provided with a frame 1, and the rolling die 19 is arranged on the body 21, and the rolling die 19 is arranged on the body 21. The pressing die 19 is driven by the second rotating motor 22 below the body 21 , the rolling die 19 is fixed on the table of the body 21 by a clamp, and the rotating direction of the rolling die 19 is opposite to that of the rolling head 2 . The top of the frame 1 is slidably provided with a support beam 3, the rolling head 2 is driven by a first rotating motor 4, and the motor base of the first rotating motor 4 is rotationally connected with the end of the support beam 3, the The bottom of the frame 1 is provided with a first pulley 5 near the rear end, the first pulley 5 is in sliding contact with the edge of the lifting cam 6, the rotating shaft 7 of the lifting cam 6 is driven by a lifting motor 8...

Embodiment 2

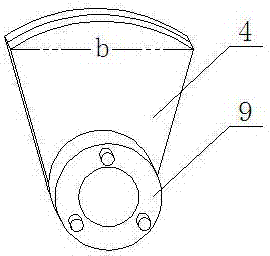

[0021] On the basis of Embodiment 1, in this embodiment, the shifting block 13 is arranged in an arc shape.

Embodiment 3

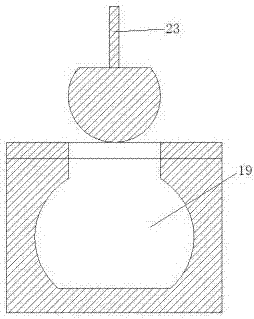

[0023] On the basis of Embodiment 1, in this embodiment, the rolling head 2 is set in a bowl shape with an arc-shaped bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com