Multi-functional agricultural product processing equipment

A multi-functional technology for agricultural product processing, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of peanut quality reduction, strong force, peanut breaking, etc., and achieve the effect of improving the effect, preventing position deviation, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 5 Shown:

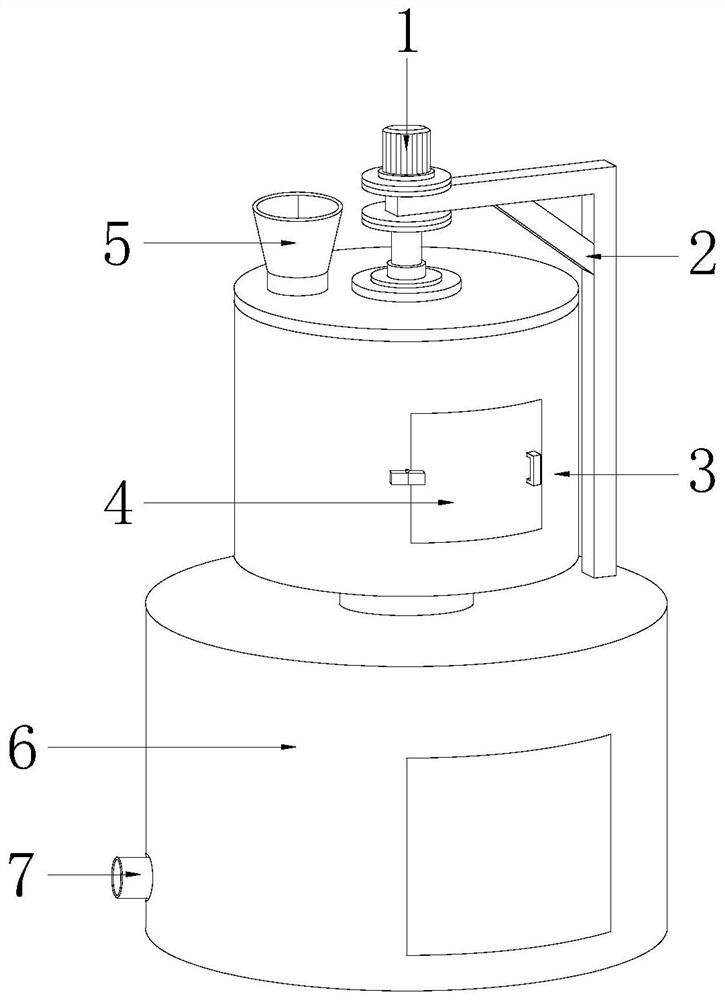

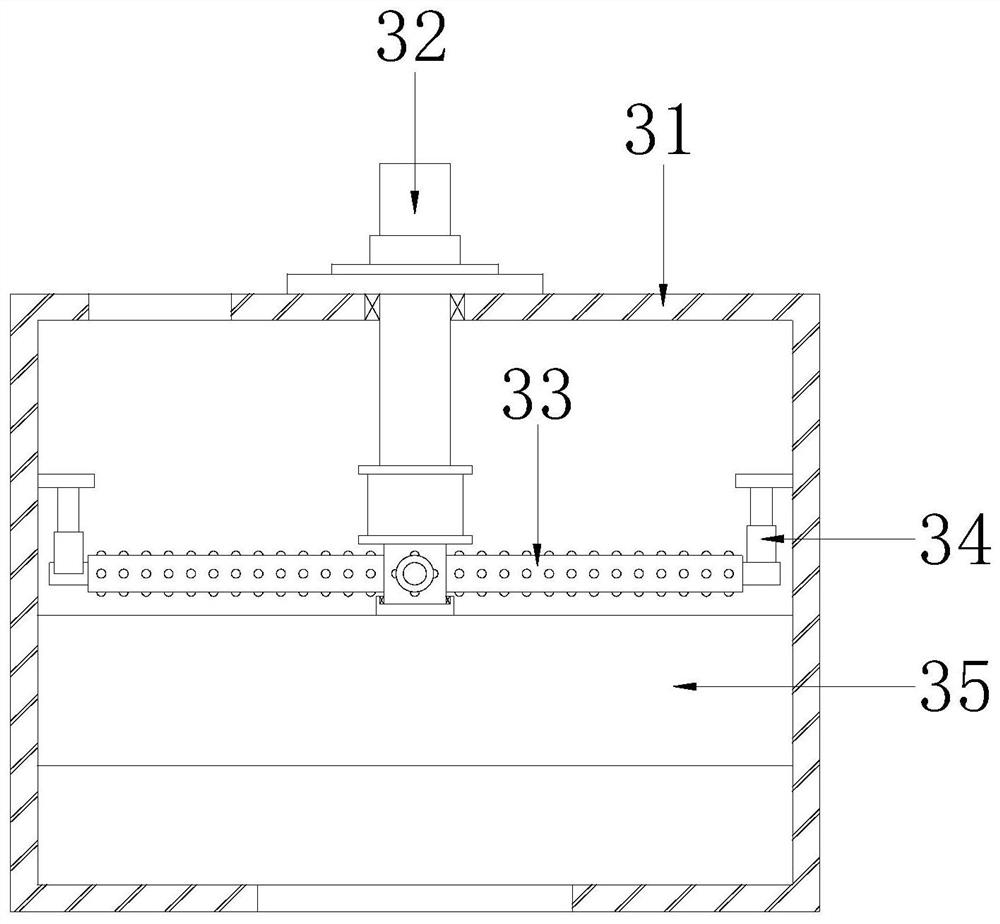

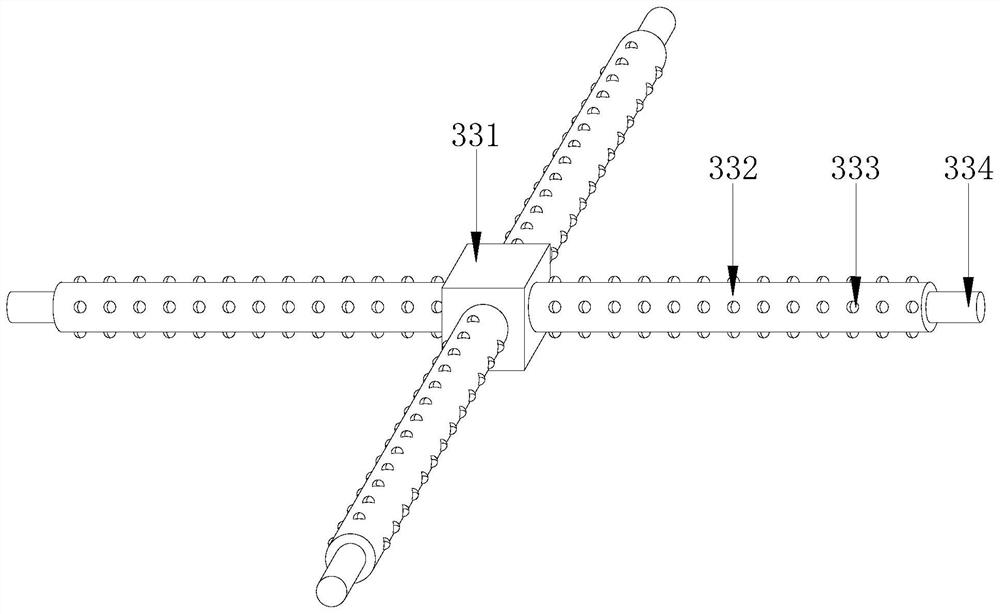

[0025] The present invention is a kind of multifunctional agricultural product processing equipment, and its structure comprises motor 1, support frame 2, peeling box 3, box door 4, feeding hopper 5, dust collection box 6, exhaust port 7, and described motor 1 is fixedly installed On the upper end of the support frame 2, and the lower end of the support frame 2 is welded on the upper surface of the dust collection box 6, the output end of the motor 1 rotates synchronously with the inside of the peeling box 3, and a box door 4 is installed on the outside of the peeling box 3, and the The feed hopper 5 is fixedly installed on the top of the peeling box 3 and communicates with each other. The peeling box 3 is arranged in the middle of the upper end of the dust collection box 6 and communicates with each other. The inside of the dust collection box 6 is embedded with an exhaust port 7. The peeling box 3 includes a box body...

Embodiment 2

[0032] as attached Image 6 to attach Figure 7 Shown:

[0033] Wherein, the toggle mechanism 35 includes a fixed frame 351, a cam 352, a toggle plate 353, and a limit ball 354. The fixed frame 351 is fixedly installed inside the box body 31, and a cam 352 is installed inside the fixed frame 351, so The top of the cam 352 is in conflict with the bottom surface of the toggle plate 353, the limit ball 354 is installed in the middle of the upper end of the toggle plate 353 by clearance fit, and the toggle plate 353 is installed inside the upper end of the fixed frame 351, and the cam 352 is set There are two, respectively mounted on the left and right ends of the lower surface of the toggle plate 353, and rotate asynchronously, so that the bottom of the toggle plate 353 is pushed asynchronously, so that the left and right ends of the toggle plate 353 swing, thereby turning the toggle plate 353 The peanuts on the plate 353 are moved upwards.

[0034] Wherein, the toggle plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com