Rice huller with protective structure for agricultural production

A technology of protective structure and shelling machine, applied in agriculture, grain shelling, application and other directions, can solve the problems of low grain accuracy, poor applicability, low production efficiency, etc., and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

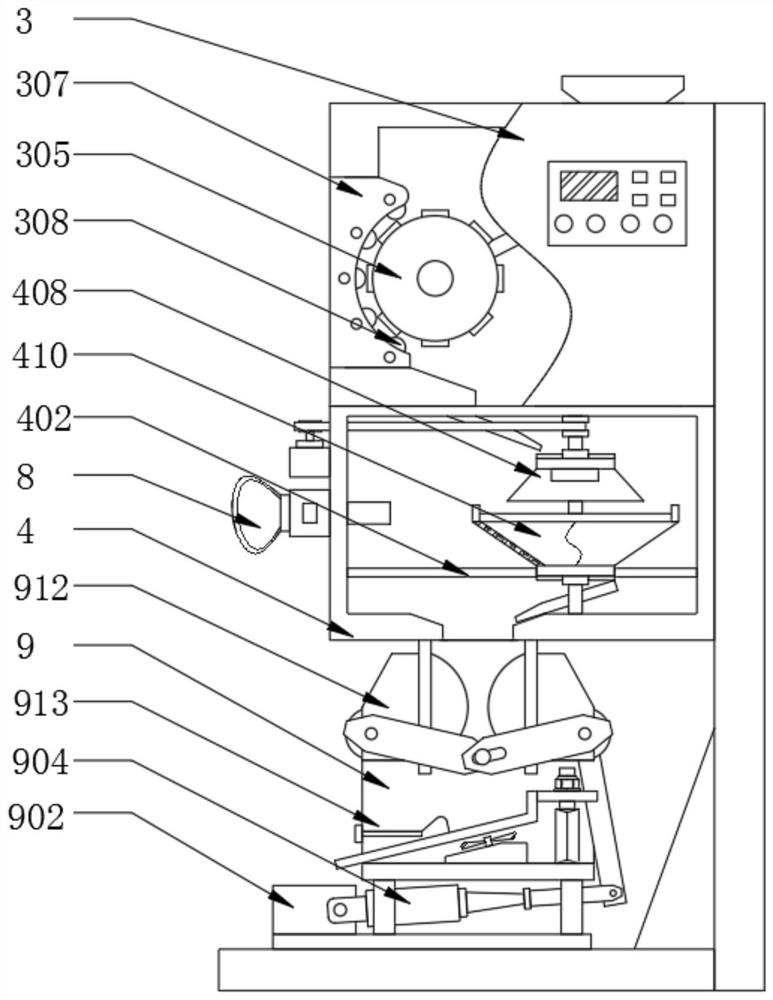

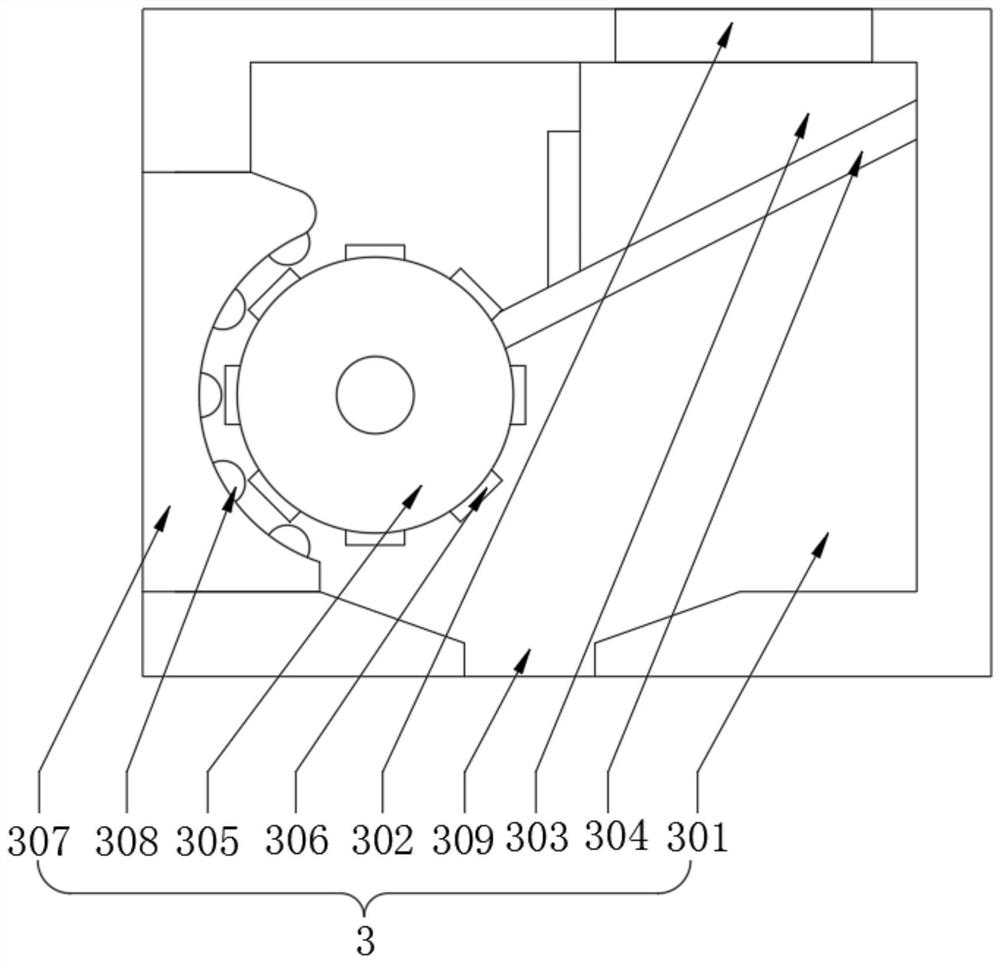

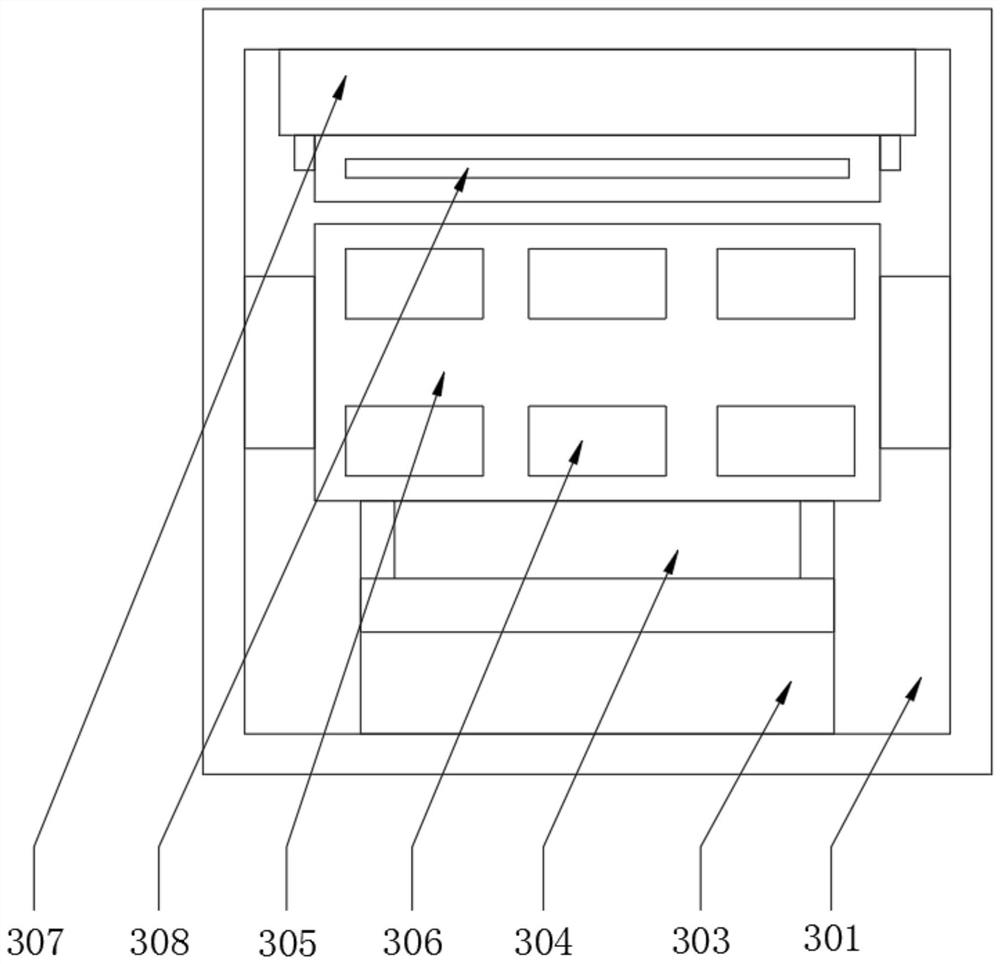

[0030] see Figure 1-8 , the present invention provides a technical solution: including a base 1 and a deburring mechanism 3, a mounting plate 2 is fixedly installed on the side end surface of the base 1, and a deburring mechanism 3 is installed on the inner side of the top of the mounting plate 2, and the deburring mechanism 3 includes Body 301, feed port 302, storage bin 303, blanking plate 304, runner 305, plastic roller block 306, guide plate 307, driven roller 308 and first passage 309, the right side of the body 301 top is provided with an inlet. The feed port 302, and the bottom of the feed port 302 is provided with a storage bin 303, the bottom of the storage bin 303 is equipped with a blanking plate 304 inclined to the lower left corner, and the bottom end of the blanking plate 304 is rotated and installed with a runner 305, the runner The surface of 305 is attached with a plastic grinding block 306, and the left side of the runner 305 is provided with a guide plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com