Garbage treatment device for building

A technology for garbage disposal and construction, applied in the direction of grain processing, etc., can solve the problems of increasing the time cost and labor cost of centralized garbage transportation, inconvenient moving and handling, and unfavorable recycling, so as to shorten the time cost and labor, and reduce the time cost. And the effect of high labor cost, crushing efficiency and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

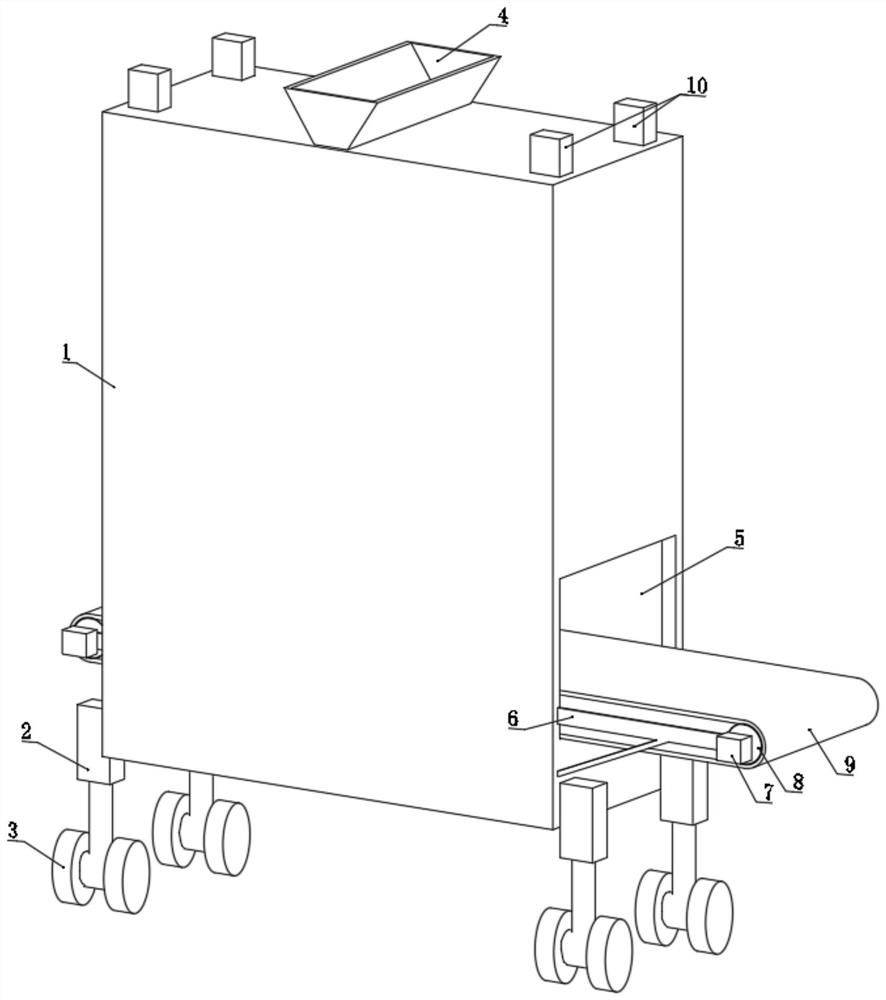

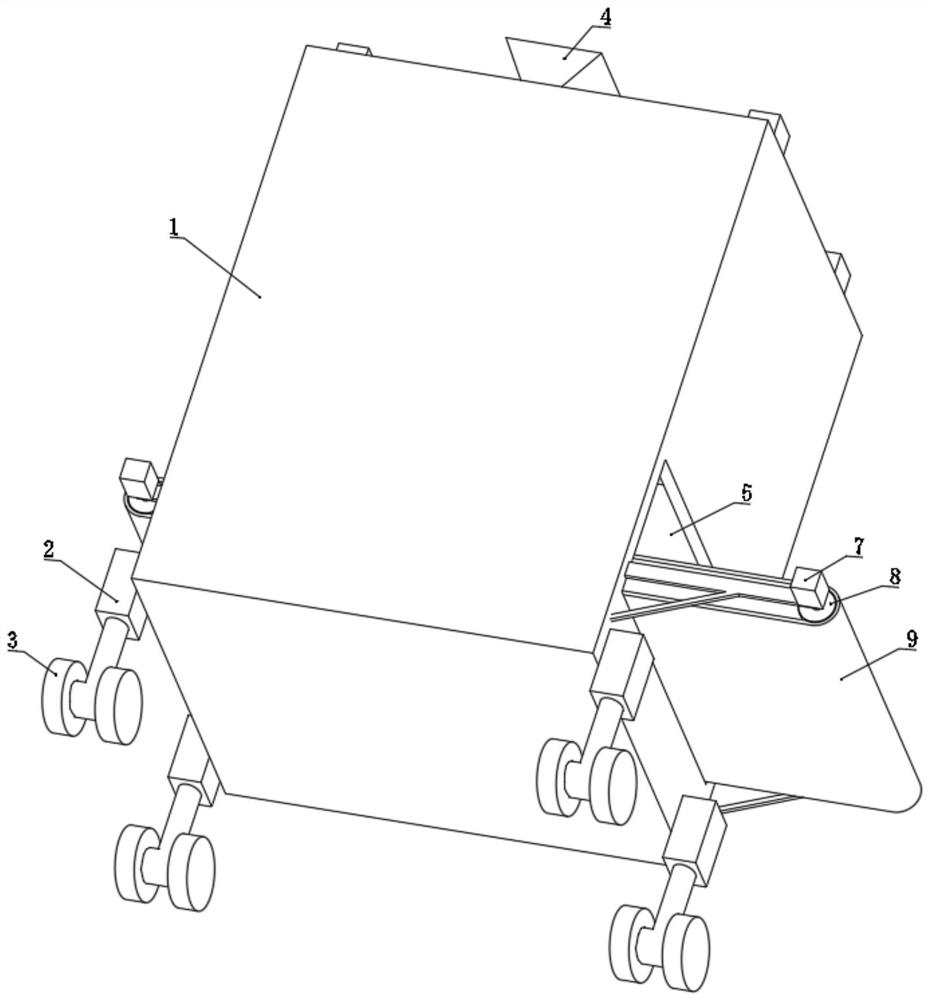

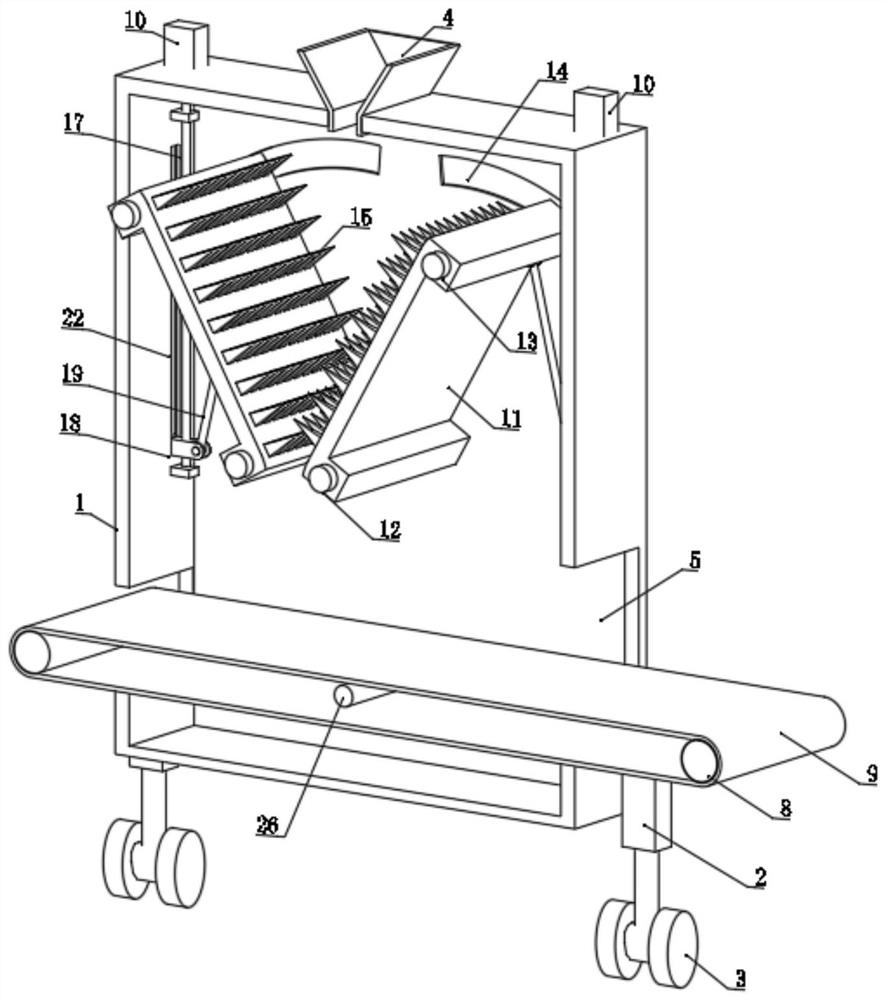

[0036] refer to Figure 1-4 , a construction waste treatment device, comprising a box body 1, a plurality of mounting seats 2 are installed on the bottom of the box body 1, and moving wheels 3 are installed on the bottom ends of the mounting seats 2, and the moving wheels 3 are four in total, and are symmetrical Distributed, the processing device of the present invention can realize convenient movement through four moving wheels 3, avoiding the time cost and labor, equipment and other costs caused by transporting garbage.

[0037] A hopper 4 is installed on the top wall of the box 1, and the bottom of the hopper 4 communicates with the inside of the box 1. Construction waste, such as bricks, concrete blocks, etc., is loaded from the hopper 4 to the box by excavators and other engineering equipment. within 1.

[0038] One side of the bottom of the box body 1 is provided with a side outlet 5, and the interior of the box body 1 is horizontally provided with a conveying mechanism...

Embodiment 2

[0049] When the crusher crushes bricks and concrete blocks, the crushed garbage and steel bars may be stuck between the crushing cones 15. Therefore, the second embodiment is based on the first embodiment above, and at the same time The following technical solutions are proposed:

[0050] refer to Figure 5-9 , the inside of the box body 1 is vertically symmetrically installed with two separation plates 16 at a position between the two crushers, and the separation plates 16 are all fixed to the inner wall of the box body 1, and the two separation plates 16 are all fixed. A through hole 25 corresponding to the crushing cone 15 is opened through, a bottom outlet 23 is opened at the bottom of the box body 1 , and leak holes 24 are uniformly provided on the conveyor belt 9 .

[0051] The size of the through hole 25 provided on the separating plate 16 needs to ensure that the crushing cone 15 will not be affected when the rolling plate 11 swings.

[0052] Since the separation pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com