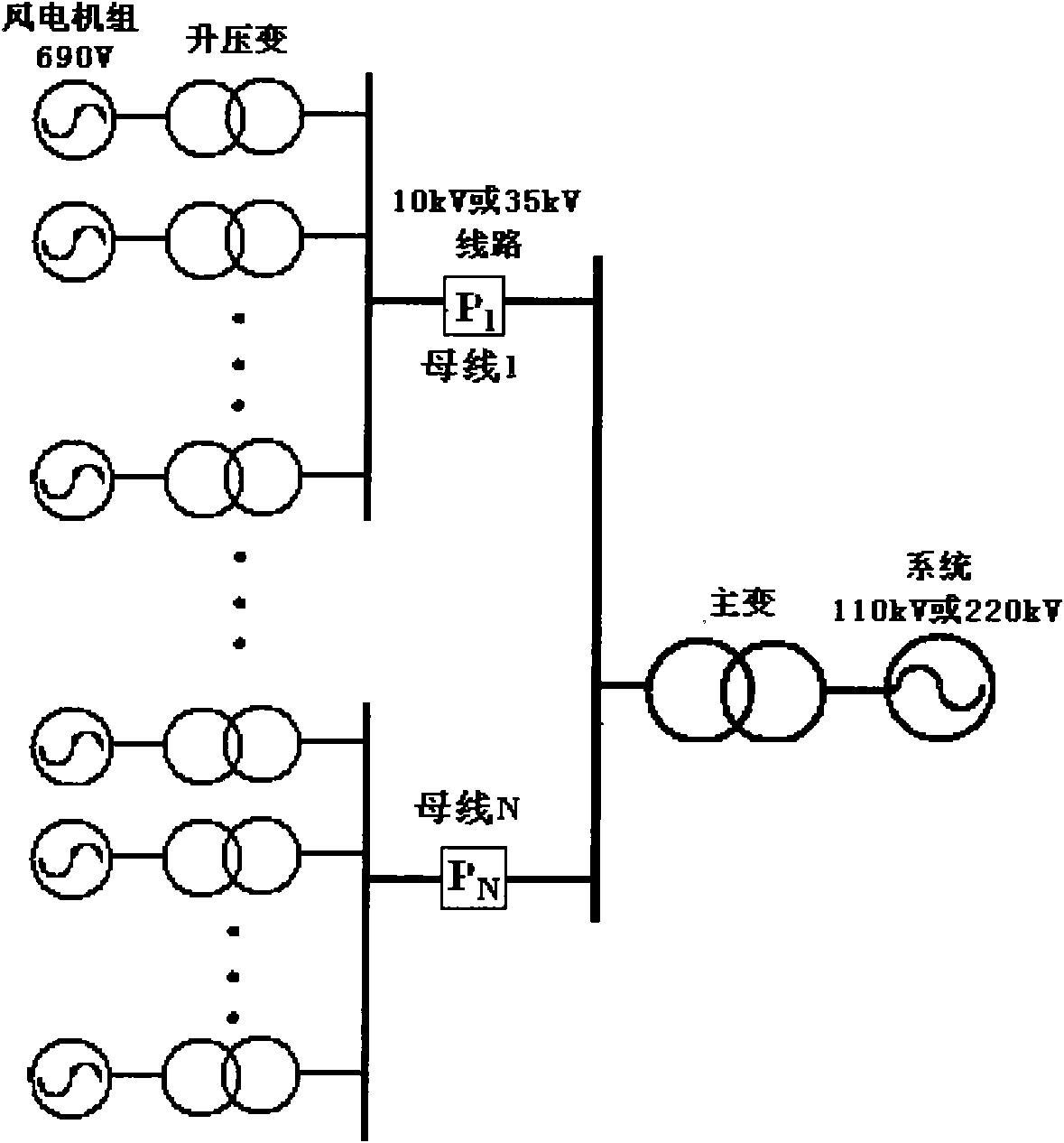

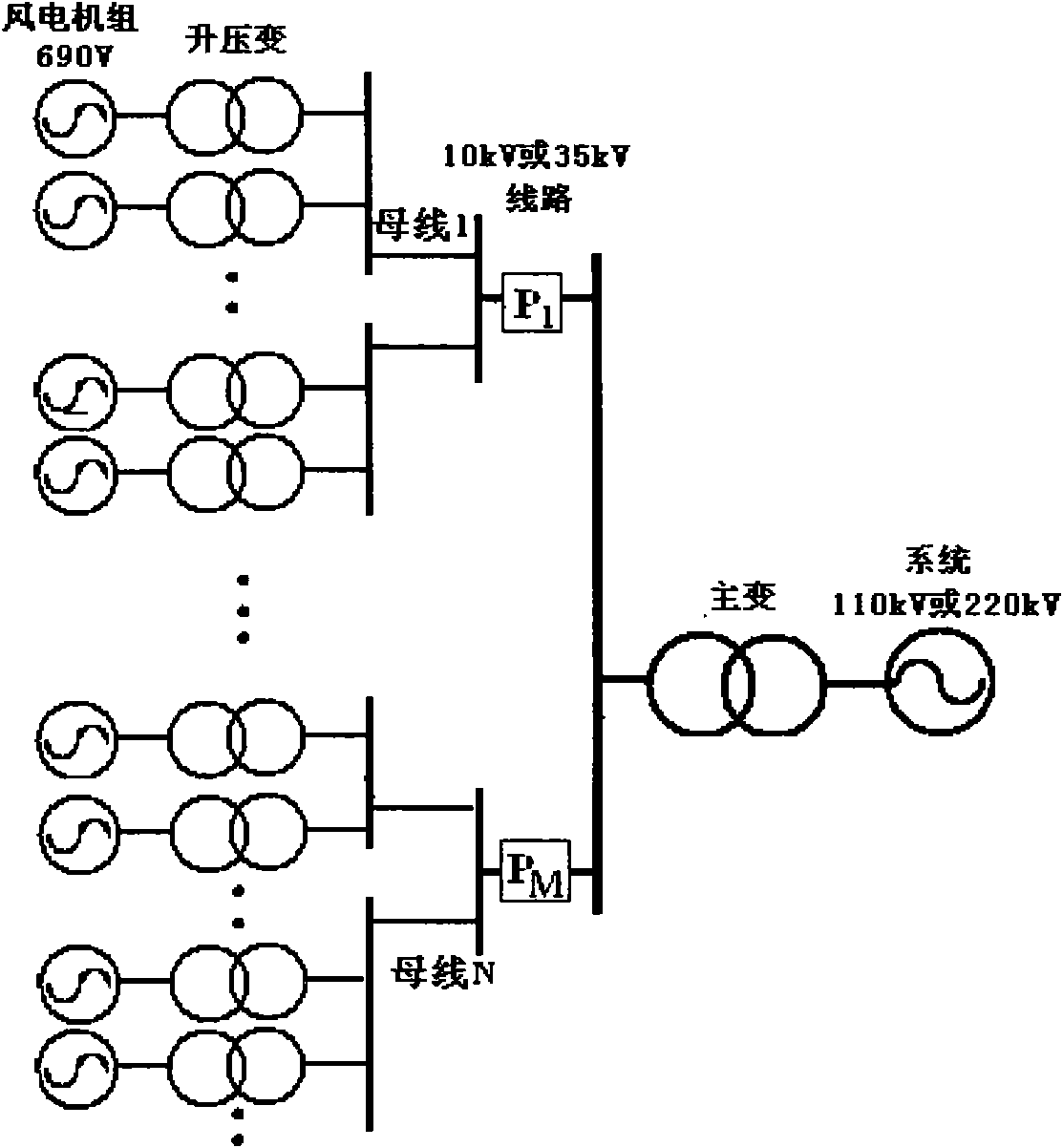

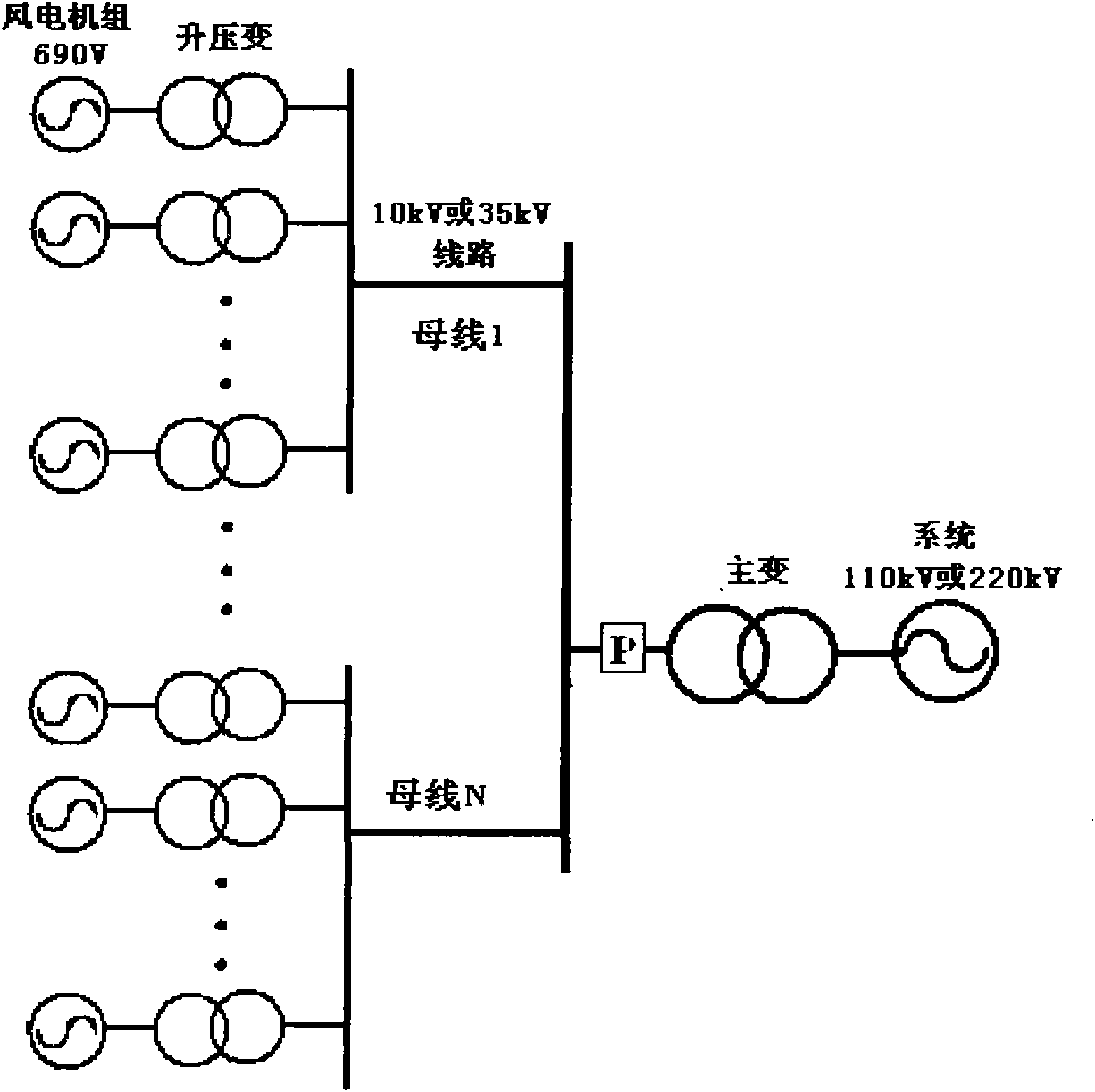

Wind power station whole low voltage ride through (LVRT) system

A low-voltage ride-through and wind farm technology, applied in wind power generation, single-network parallel feed arrangement, etc., can solve the problems of unit damage, lower capital return rate, and high cost of equipment transformation, so as to facilitate engineering construction, increase heat dissipation burden, The effect of fewer devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0071] like Figure 4 The circuit structure is the first embodiment of the LVRT device of the present invention, including:

[0072] There are three bypass switches KA, KB and KC, and the two ends of each bypass switch are respectively connected to the collector bus and one of the three phases of the power grid. Among them, each bypass switch is composed of a thyristor connected in positive and negative parallel, and each thyristor is connected with such as Image 6 The LVRT control unit shown ( Figure 4 Not shown in ) connection, receiving the control signal of the LVRT control unit to perform the breaking operation; and

[0073] Three single-phase inverters IA, IB and IC, the AC interfaces of the three inverters are respectively connected in parallel with the three bypass switches, the DC interfaces of the three inverters are connected in series with the same capacitor C, and the capacitor C is connected in parallel to a DC A chopper, the DC chopper is composed of a resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com