Engine exhaust gas purification device

An exhaust gas purification device and engine technology, which is applied to exhaust devices, engine components, combustion engines, etc., to achieve high reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

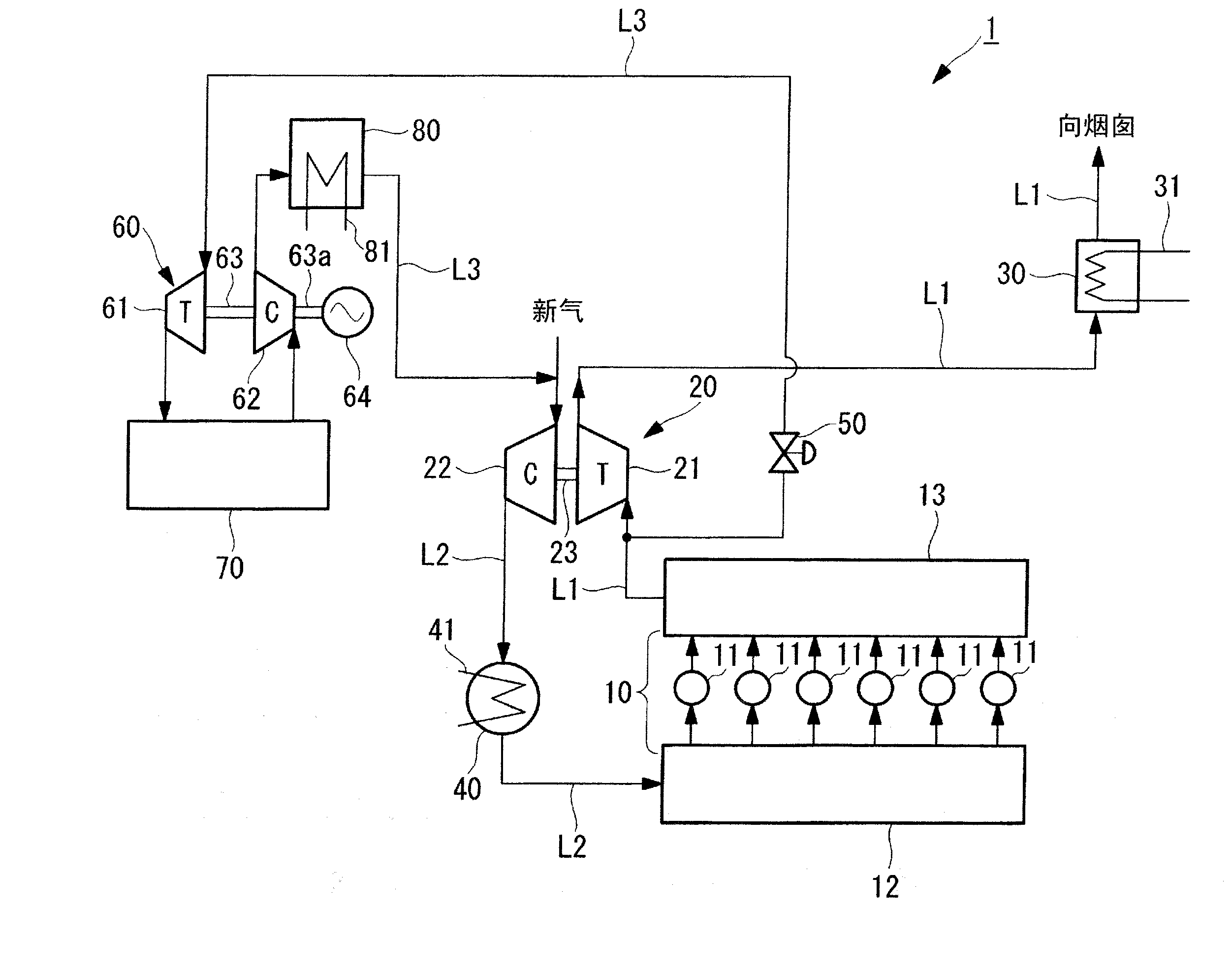

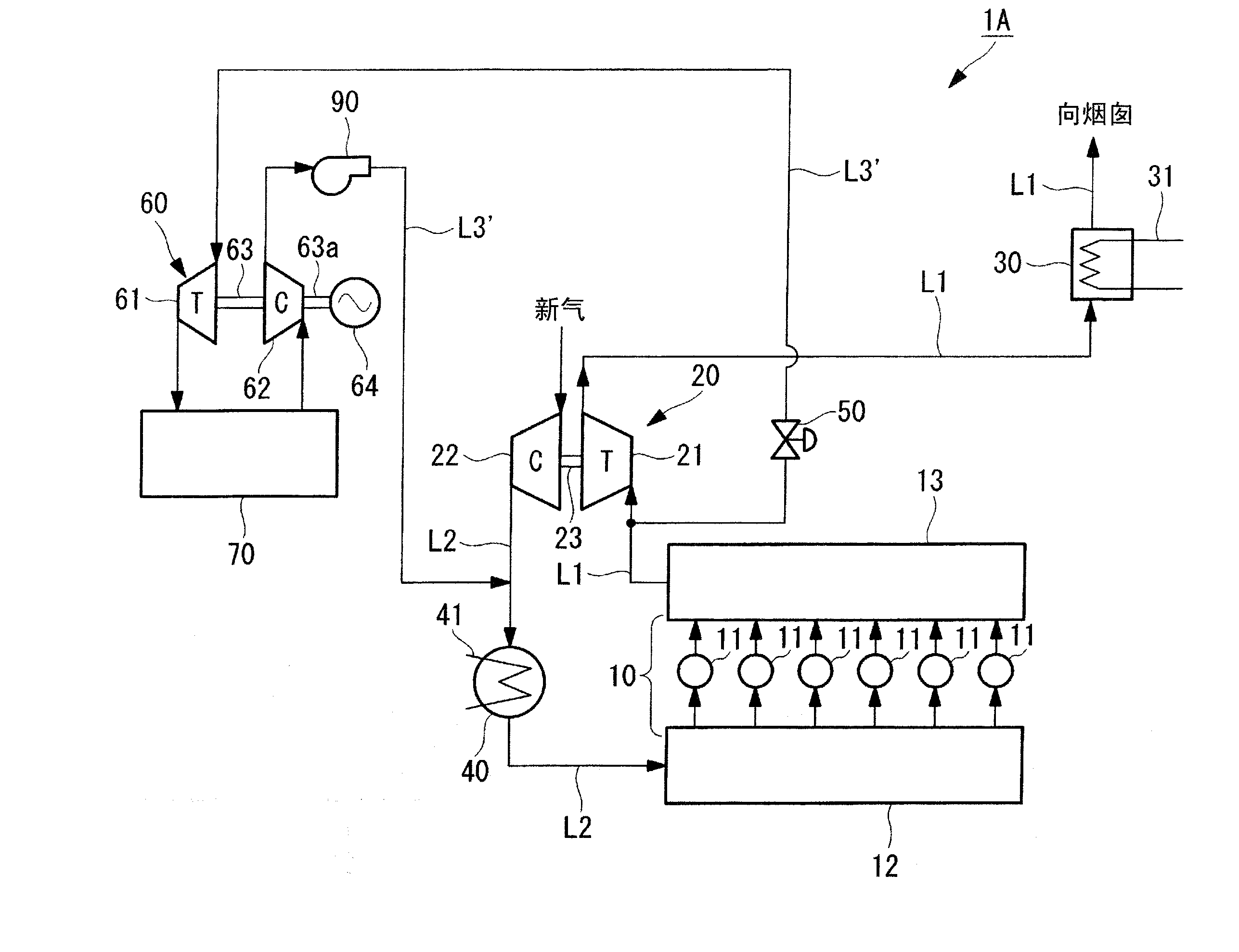

[0029] Hereinafter, regarding the engine exhaust gas purification device of the present invention, based on figure 1 , to describe the first embodiment. It should be noted, figure 1 The schematic configuration diagram of the engine exhaust gas purifying device shown is a configuration example mainly incorporated into the main engine intake and exhaust system serving as the main engine of the ship.

[0030] figure 1 The shown engine exhaust gas purification device (hereinafter referred to as "purification device") 1 is to remove harmful sulfur oxides or nitrogen oxides, etc. A device for reducing and removing substances (air pollutants).

[0031] A main engine 10 for propulsion of a ship is mounted in the ship, and exhaust gas discharged from the main engine 10 is discharged to the atmosphere through a funnel.

[0032] The main engine 10 includes a plurality of cylinders 11 , an air supply manifold 12 , and an exhaust manifold 13 . Fuel supplied from a fuel supply system n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com