Environment-friendly antibacterial fur after-finishing agent and preparation method thereof

A post-finishing and environment-friendly technology, applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve single function, affect production, Environmental pollution and other problems, to achieve the effect of improving brightness, improving environmental protection performance, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

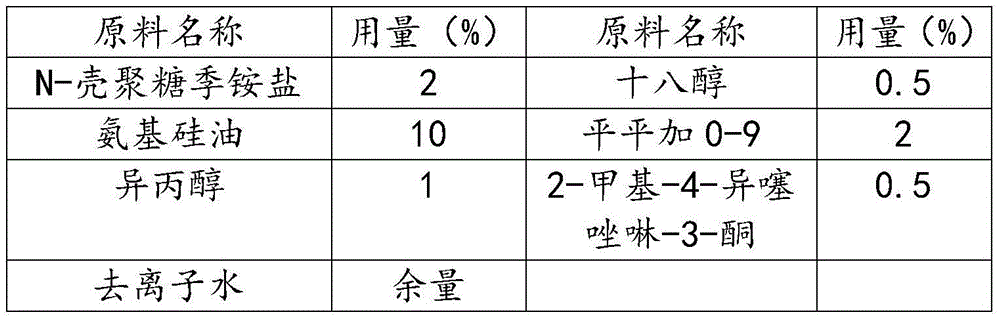

[0055] The composition of each raw material in the environment-friendly antibacterial fur finishing agent of the present embodiment is as follows according to weight percentage:

[0056]

[0057] A preparation method of an environment-friendly antibacterial fur finishing agent, comprising the steps of:

[0058] (1) Put fatty alcohol, organosilicon, and nonionic surfactant into the reactor, and heat to 50-60 degrees, and stir evenly after dissolving;

[0059] (2) Properly dissolve the quaternary ammonium salt with 20% deionized water, and set aside;

[0060] (3) Slowly add the remaining deionized water into the reactor, after mixing evenly, start to cool down;

[0061] (4) Cool the material to 10-15 degrees, add quaternary ammonium salt solution and preservative, and stir well to obtain an environment-friendly antibacterial fur finishing agent.

Embodiment 2

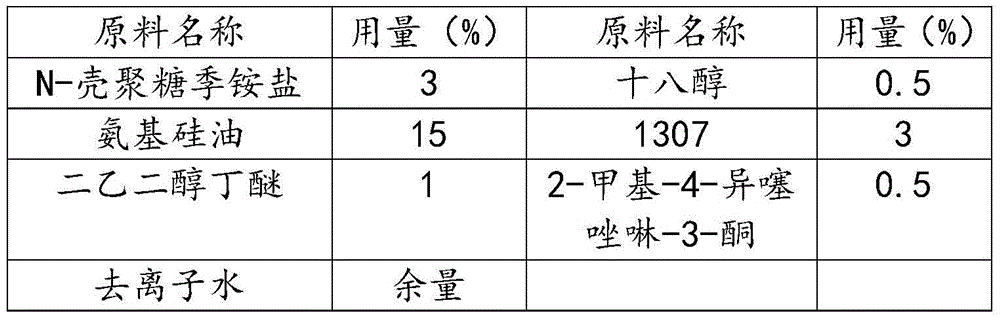

[0063] The composition of each raw material in the environment-friendly antibacterial fur finishing agent of the present embodiment is as follows according to weight percentage:

[0064]

[0065] A preparation method of an environment-friendly antibacterial fur finishing agent, comprising the steps of:

[0066] (1) Put fatty alcohol, organosilicon, and nonionic surfactant into the reactor, and heat to 80-90 degrees, and stir evenly after dissolving;

[0067] (2) Properly dissolve the quaternary ammonium salt with 50% deionized water, and set aside;

[0068] (3) Slowly add the remaining deionized water into the reactor, after mixing evenly, start to cool down;

[0069] (4) Cool the material to 25-30 degrees, add a quaternary ammonium salt solution and a preservative, and stir evenly to obtain an environment-friendly antibacterial fur finishing agent.

Embodiment 3

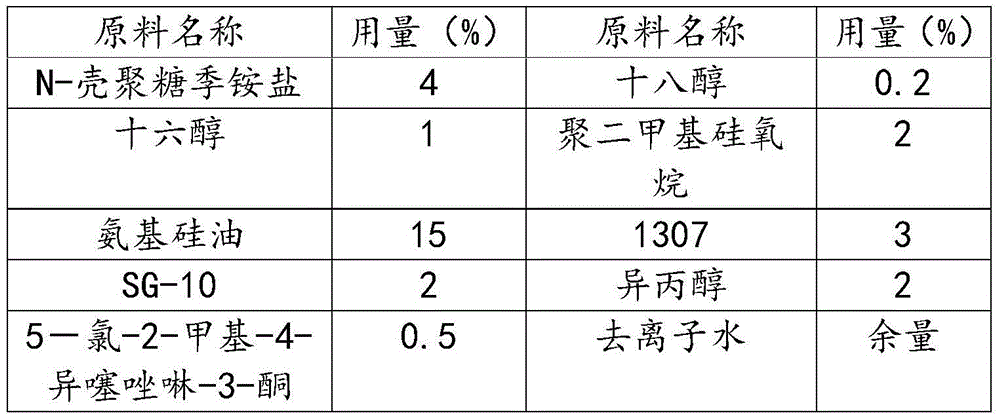

[0071] The composition of each raw material in the environment-friendly antibacterial fur finishing agent of the present embodiment is as follows according to weight percentage:

[0072]

[0073] A preparation method of an environment-friendly antibacterial fur finishing agent, comprising the steps of:

[0074] (1) Put fatty alcohol, organosilicon, and nonionic surfactant into the reactor, and heat to 50-60 degrees, and stir evenly after dissolving;

[0075] (2) Properly dissolve the quaternary ammonium salt with 25% deionized water, and set aside;

[0076] (3) Slowly add the remaining deionized water into the reactor, after mixing evenly, start to cool down;

[0077] (4) Cool the material to 15-20 degrees, add quaternary ammonium salt solution and preservative, and stir well to obtain an environment-friendly antibacterial fur finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com