Vacuum kneading-and-defoaming device

一种混揉、脱泡的技术,应用在混合机、液体脱气、运输和包装等方向,能够解决脱泡不充分等问题,达到提高作业效率、避免品质降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

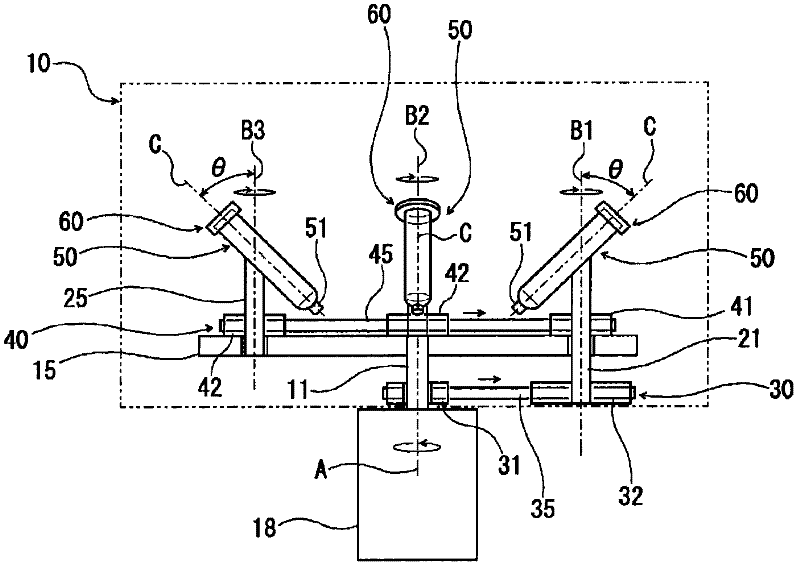

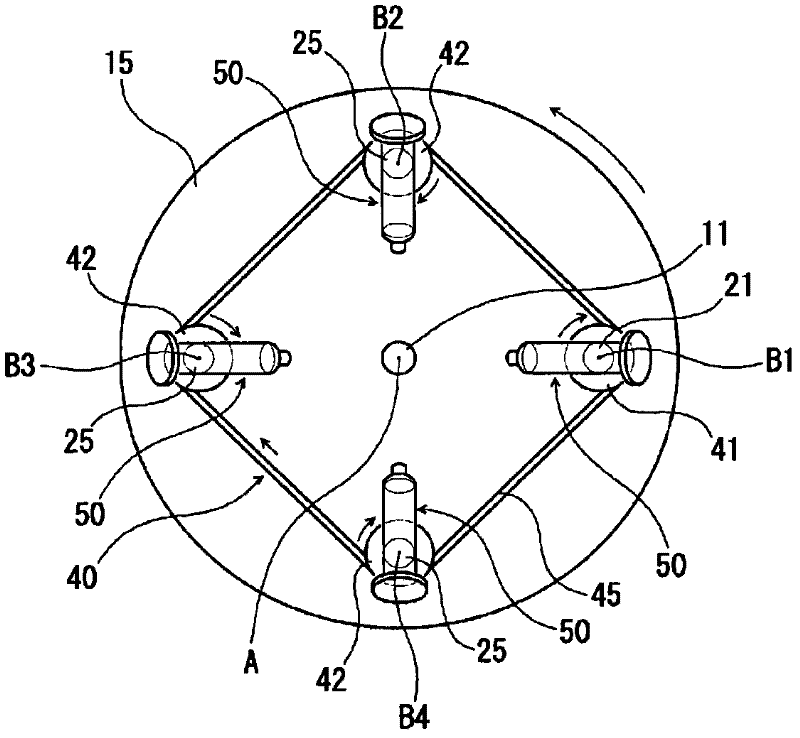

[0034] figure 1 It is an explanatory cross-sectional view showing an outline of a basic structure in an example of the vacuum kneading and defoaming device according to the first embodiment of the present invention, figure 2 is viewed from the vertical direction above figure 1 The top view of the vacuum kneading and defoaming device shown.

[0035] This vacuum kneading and defoaming device is provided with: a cylindrical chamber 10 forming a closed space inside; The driving motor 18 of the driving rotating shaft body 11 for the revolution of the drive; the disc-shaped rotating plate 15 for revolution rotating in the horizontal plane centered on the reference driving rotating shaft A; The rotating center axis extending parallel to the axis A is the operating rotating shaft body 21 for autorotation, which is provided to rotate freely; A plurality of self-rotating driven rotating shafts 25 provided freely in the center; an operating rotating shaft driving mechanism 30 for rot...

no. 2 approach

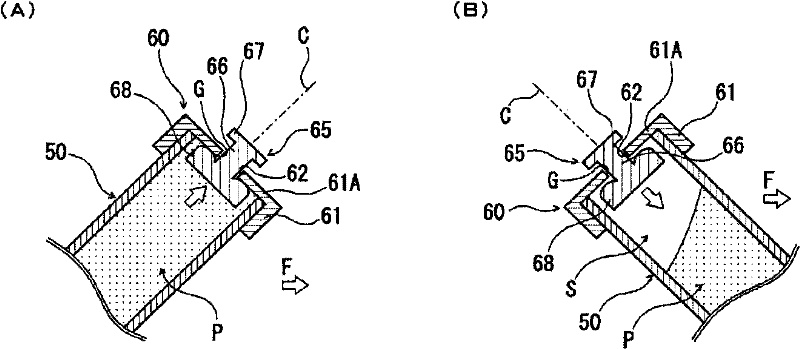

[0061] The vacuum kneading and degassing device of the second embodiment of the present invention uses the following structure: as the syringe-shaped container 50, an opening on one end side for filling the paste material P into the syringe-shaped container 50 is provided with a Cover member 70 for exhaust function.

[0062] Cover part 70, such as Figure 5 (A) and Figure 5 As shown in (B), a bottomed cylindrical holder that is detachably mounted on the opening of the one end side of the syringe-shaped container 50 so as to accommodate one end of the syringe-shaped container 50 and block the opening of the syringe-shaped container 50 The frame 61 and the gas permeable membrane 75 that does not permeate the paste material are provided on the inner surface of the end wall 61A of the holder 61 so as to cover the through hole 62 formed in the center of the end wall 61A.

[0063] The gas permeable membrane 75 is, for example, a film-like membrane having the properties of prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com