Washing machine and washing method

a washing machine and washing method technology, applied in the field of washing machines, can solve the problems of large power consumption, large water consumption, time-consuming washing process, etc., and achieve the effects of improving cleaning efficiency, simplifying washing procedures, and simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

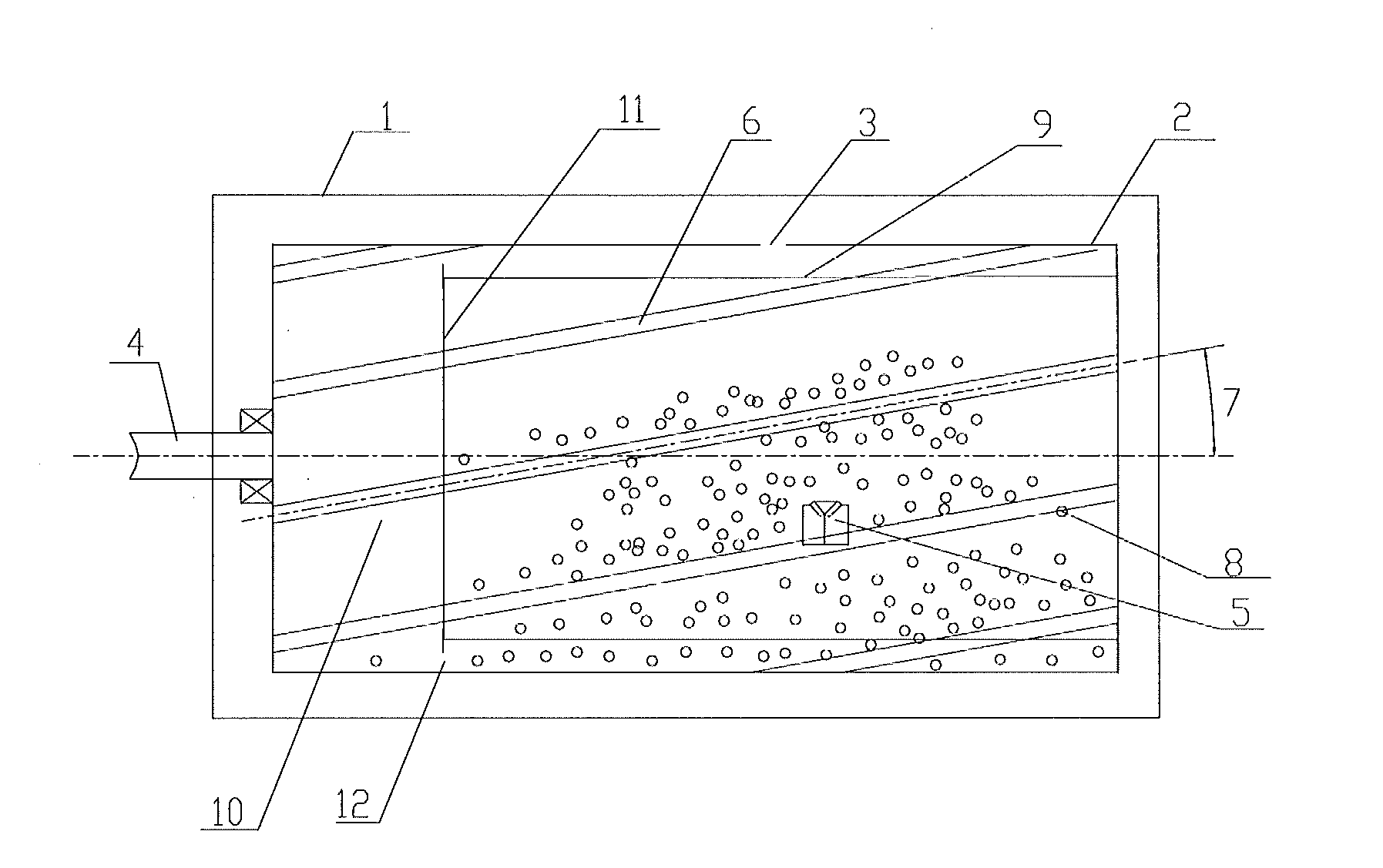

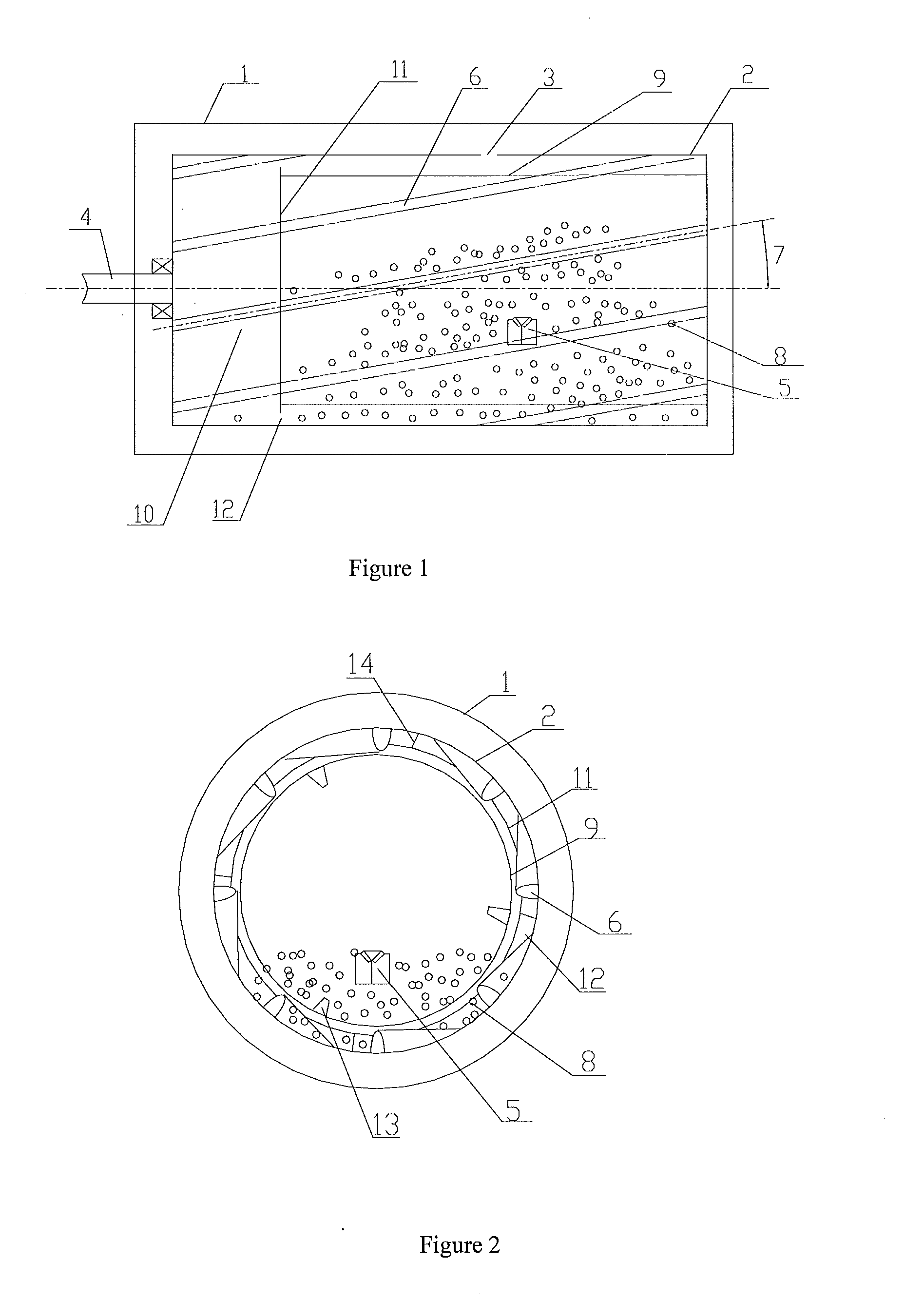

[0035]As shown in FIG. 1 and FIG. 2, a washing machine, taking a drum washing machine for example to be further described in the embodiment, includes a housing (not shown in figure), an outer cylinder 1 arranged in the housing, an inner cylinder 2 and solid particles 8 as washing medium. Among them, the outer cylinder 1 is fixed without rotation, mainly used for holding water; the inner cylinder 2 is used for washing. The inner cylinder 2 is arranged in the outer cylinder 1. The side wall of the inner cylinder 2 is uniformly provided with a plurality of opening holes 3 through which washing water pass. The diameter of the opening holes 3 is smaller than the diameter of the solid particles 8, and the shape of the opening holes 3 can be round, rectangle, polygon etc. The inner cylinder 2 is driven to rotate by the driving device 4. The upper of the outer cylinder 1 is provided with a water inlet (not shown in figure) for adding water during the washing and rinsing process. The lower o...

embodiment 2

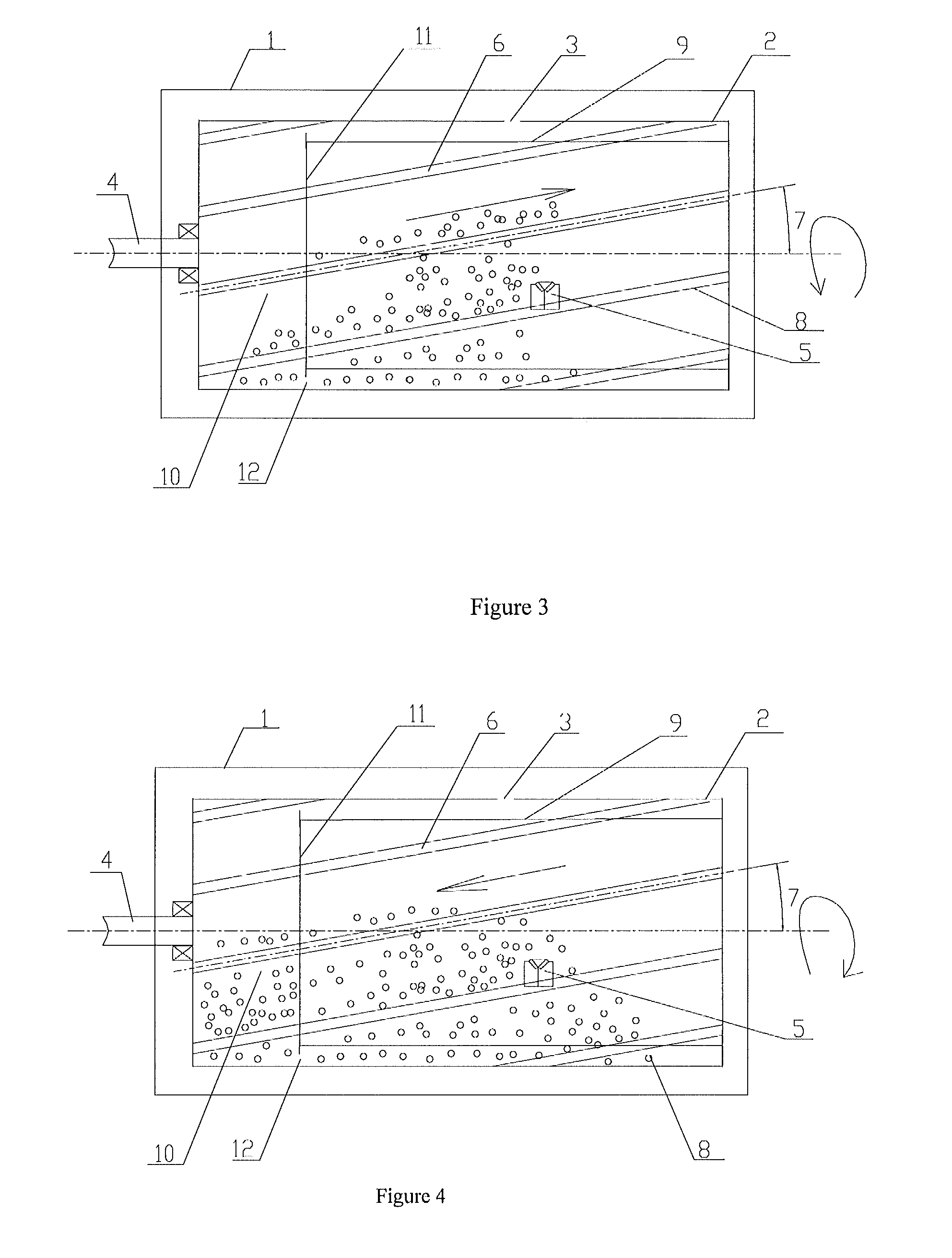

[0063]The difference from Embodiment 1 is that step 5 in Embodiment 1 is performed firstly. The inner cylinder 2 and the extension part are driven to rotate with high-speed, and the rotation direction of the inner cylinder 2 and the extension part is same with the inclined direction of the scraper blades 6. The clothes 5 and the particles 8 dewater. During dewatering, it is realized to separate the clothes 5 from the particles 8. At the same time, parts of the particles 8 is driven to move obliquely downward to the storage space 10 by the scraper blades 6, return to the storage space 10.

[0064]Then step 4 in Embodiment 1 is performed. The inner cylinder 2 and extension part are driven to rotate with the washing rotation speed. The rotation direction of the inner cylinder 2 and the extension part is same with the inclined direction of the scraper blades 6, and operating continuously along the direction, so that the residual particles 8 can continue to be separated and recycled, to be ...

embodiment 3

[0065]The difference from Embodiment 1 is that step 4 in embodiment 1 is deleted and directly performing step 5 in Embodiment 1. The inner cylinder 2 and extension part are driven to rotate with high speed, and the rotation direction of the inner cylinder 2 and the extension part is same with the inclined direction of the scraper blades 6. The clothes 5 and the particles 8 dewater. During dewatering, it is realized to separate the clothes 5 from the particles 8. At the same time, the particles 8 are driven move obliquely downward to the storage space 10 by the scraper blades 6, return to the storage space 10. In the process, the time for the rotation of the inner cylinder 2 with high speed is needed to be lengthened, to ensure that the particles 8 is completely recovered to the storage space 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com