Blender of melt extrusion type color 3D (three-dimensional) printing head

A technology of melt extrusion and printing head, which is applied in the direction of additive processing, etc., and can solve the problem of impure color of objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

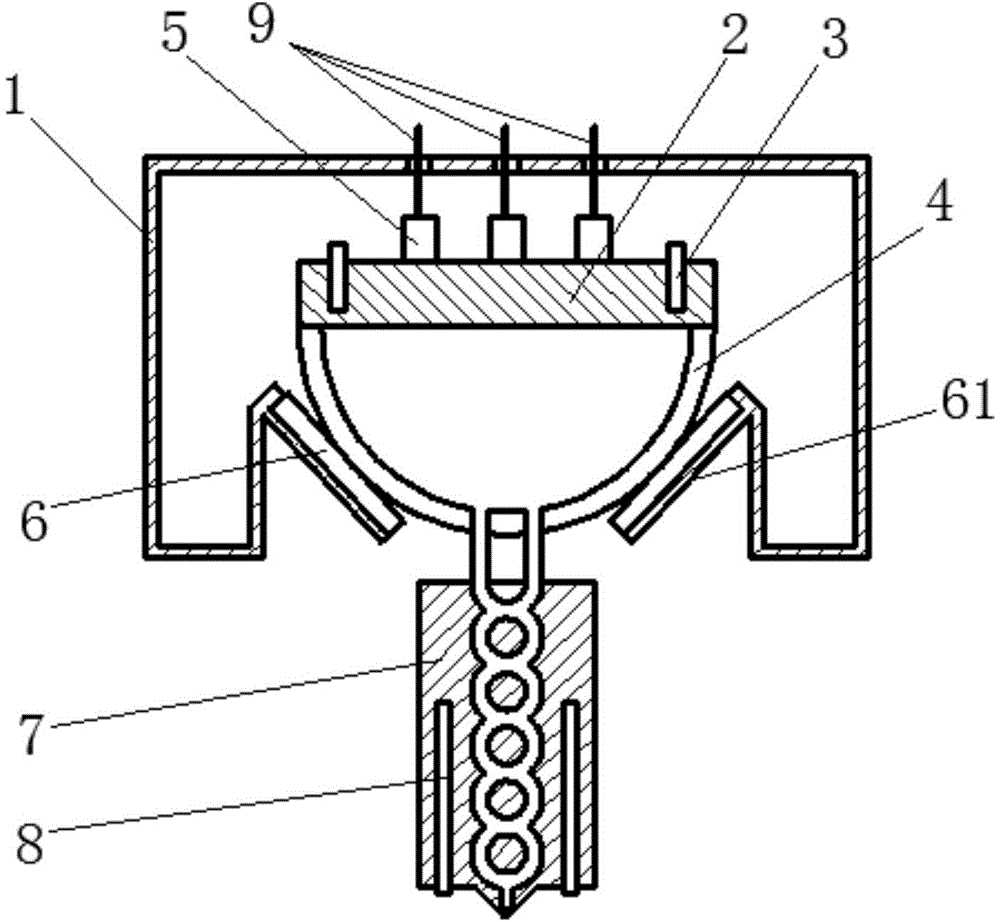

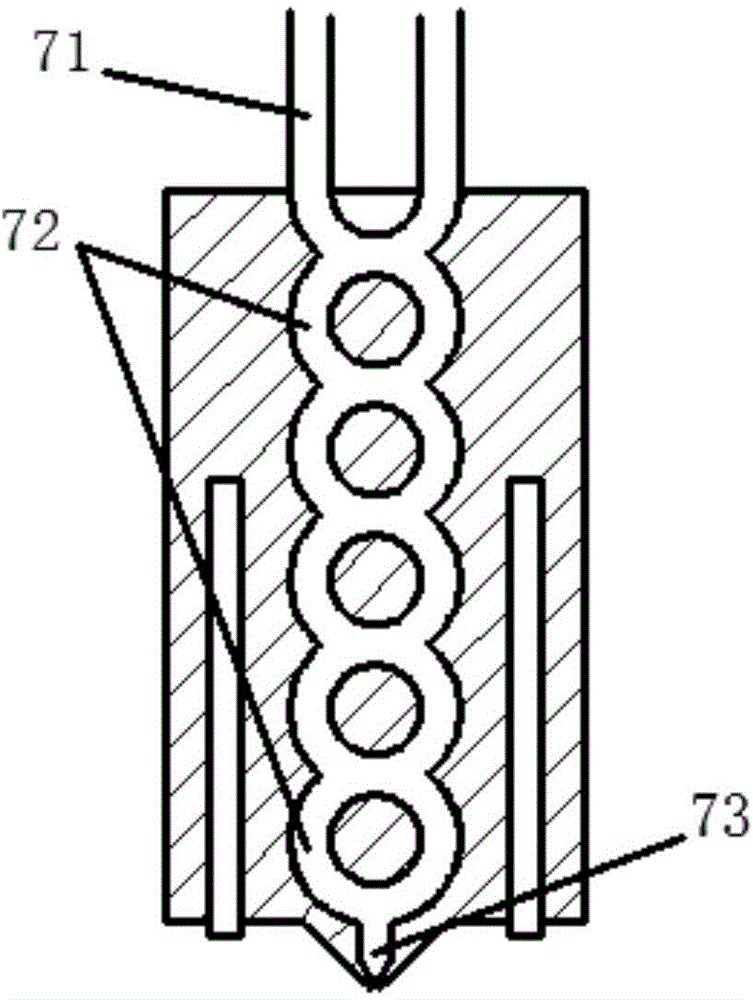

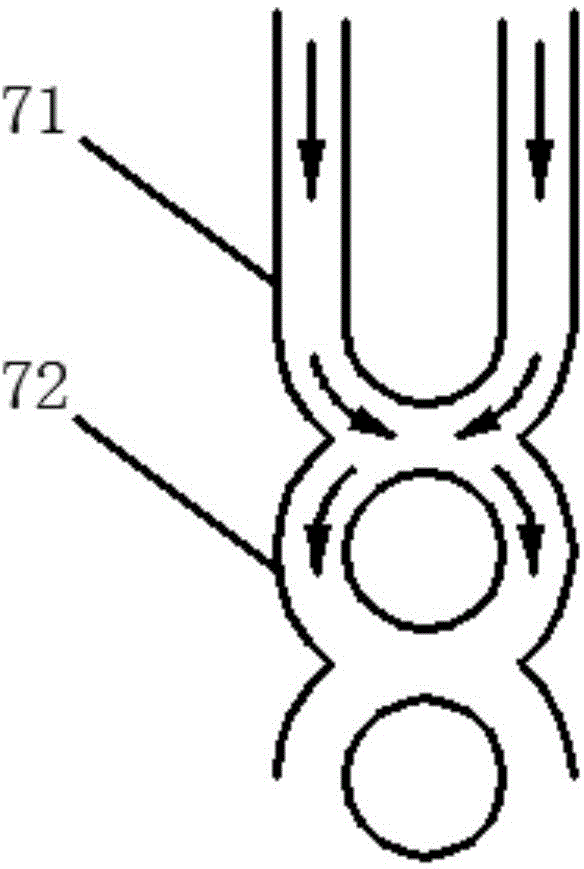

[0014] refer to figure 1 , figure 2 with image 3 , the mixer of the melt extrusion type color 3D printing head of the present invention comprises a mixing bracket 1, a heating block 2 arranged in the mixing bracket 1, a heating rod 3 inserted into the heating block 2, and a heating rod fixed on the heating block 2 The primary mixing bin 4 at the bottom, the secondary mixing bin 7 arranged at the bottom of the primary mixing bin 4 and the insulation rod 8 inserted into the inside of the secondary mixing bin 7, the mixing bracket 1 is provided with a symmetrical inclination Surface 61, a piezoelectric ceramic bimorph 6 is fixed on the symmetrical inclined surface 61, the minimum distance between the upper surface of the piezoelectric ceramic bimorph 6 and the primary mixing chamber 4 is smaller than the unilateral vibration of the piezoelectric ceramic bimorph 6 Amplitude, that is, the piezoelectric ceramic bimorph 6 is bounded by the straight state when it is not working, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com