Filling type fracture network rock test piece preparing method based on 3D printing technology

A technology of fracture network and rock specimen, which is applied in the preparation of test samples, manufacturing tools, ceramic molding machines, etc., can solve the problem of difficulty in preparing rock mass models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

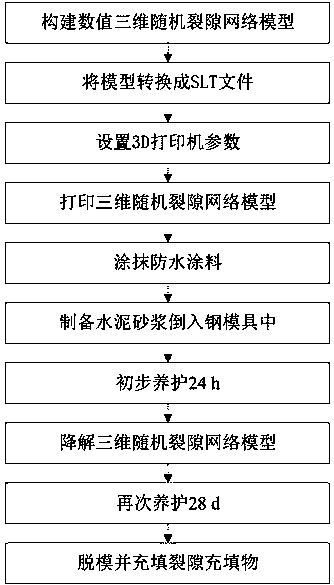

[0034] Embodiment 1: as Figure 1-3 Shown, a kind of filling type fracture network rock specimen preparation method based on 3D printing technology, described preparation method comprises the following steps:

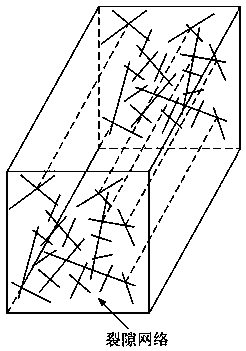

[0035] Step 1: Collect enough fracture shape and distribution characteristic data, use matlab software to write the corresponding model code, construct a three-dimensional random fracture network model, set the model size length × width × height = 10 × 10 × 20 cm, and build the model Such as figure 2 shown;

[0036] Step 2: Import the model file obtained in Step 1 into AutoCAD software and convert it into a corresponding SLT file;

[0037] Step 3: Import the SLT file into the 3D printer, and set the parameters of the 3D printer such as printing speed, printing layer, printing filling degree, printing nozzle temperature, printing material, and the distance z-offset between the nozzle and the platform; the printing speed is, the printing layer is 0.2 mm, the printing ...

Embodiment 2

[0046] Embodiment 2: as Figure 1-3 As shown, a method for preparing a filled fracture network rock specimen based on 3D printing technology, this embodiment is the same as Embodiment 1, the difference is:

[0047] Further, the steps 1 and 2 can be replaced by: collecting enough crack shape and distribution characteristic data, using matlab software to write corresponding model codes, first constructing a two-dimensional random crack network model, and then converting the two-dimensional random crack network model to Import it into AutoCAD, use the Region command to generate the fracture area, and then use the Extrude command to stretch the area to obtain the corresponding 3D fracture network model, and then output it as an SLT file.

[0048] Further, in the step five, the number of times the waterproof paint is applied is 3 times, and the application thickness is 0.4 mm;

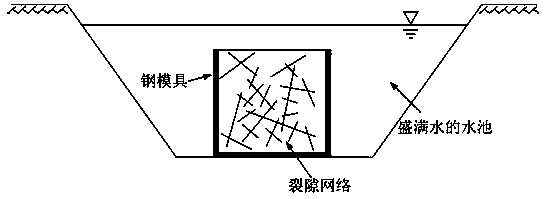

[0049] Further, Step 7: Put the cement mortar specimen obtained in Step 6 together with the steel mold ...

Embodiment 3

[0051] Embodiment 3: as Figure 1-3 As shown, a method for preparing a filled fracture network rock specimen based on 3D printing technology, this embodiment is the same as Embodiment 1, the difference is:

[0052] Further, the steps 1 and 2 can be replaced by: collecting enough crack shape and distribution characteristic data, using matlab software to write corresponding model codes, first constructing a two-dimensional random crack network model, and then converting the two-dimensional random crack network model to Import it into AutoCAD, use the Region command to generate the fracture area, and then use the Extrude command to stretch the area to obtain the corresponding 3D fracture network model, and then output it as an SLT file.

[0053] Further, in the step five, the number of times the waterproof paint is applied is 3 times; the application thickness is 0.45 mm;

[0054] Further, Step 7: Put the cement mortar specimen obtained in Step 6 together with the steel mold int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com