Wood fiber biomass loaded nano hydrated titanium dioxide composite material, and preparation method and application thereof

A technology of hydrated titanium dioxide and biomass materials, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, special compound water treatment, etc., can solve the difficulties of titanium dioxide photocatalysts and the unsatisfactory efficiency of organic pollutants , complex catalyst preparation process and other issues, to achieve good adsorption and deep removal capabilities, simple and environmentally friendly preparation process, and good photocatalytic degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of rice straw loaded nanometer hydrated titanium dioxide composite material comprises the following steps:

[0038] Using rice straw as a carrier, cut it into 4mm thin sections, dry it at 60°C for later use, weigh the rice straw into a three-neck flask, then add tetrabutyl titanate (analytical pure, content ≥ 98%) and absolute ethanol The mixed solution, the volume ratio of tetrabutyl titanate to absolute ethanol is 1:3, the solid-liquid ratio of rice straw to the mixed solution is 1g:50mL, stirring and impregnating at 30°C for 15h; drain the rice straw, press Add NaOH solution with a concentration of 0.1mol / L at a solid-to-liquid ratio of 1g:50mL, shake at 30°C for 1.5h; then wash the rice straw with water to adjust the pH to 8-9; drain the water and dry it at 60°C. That is, rice straw-supported nano-hydrated titanium dioxide composite material (RS-nHTO) was obtained.

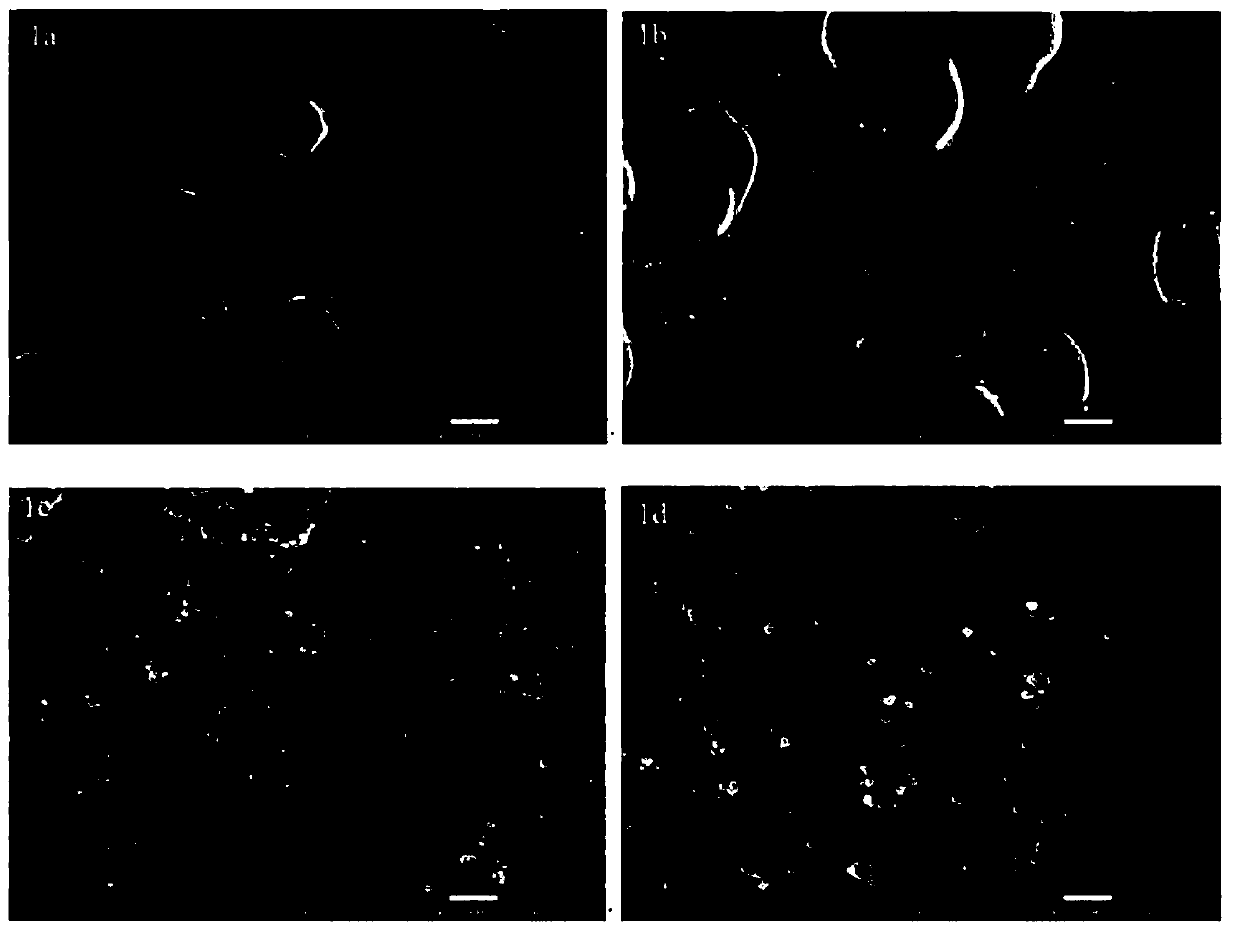

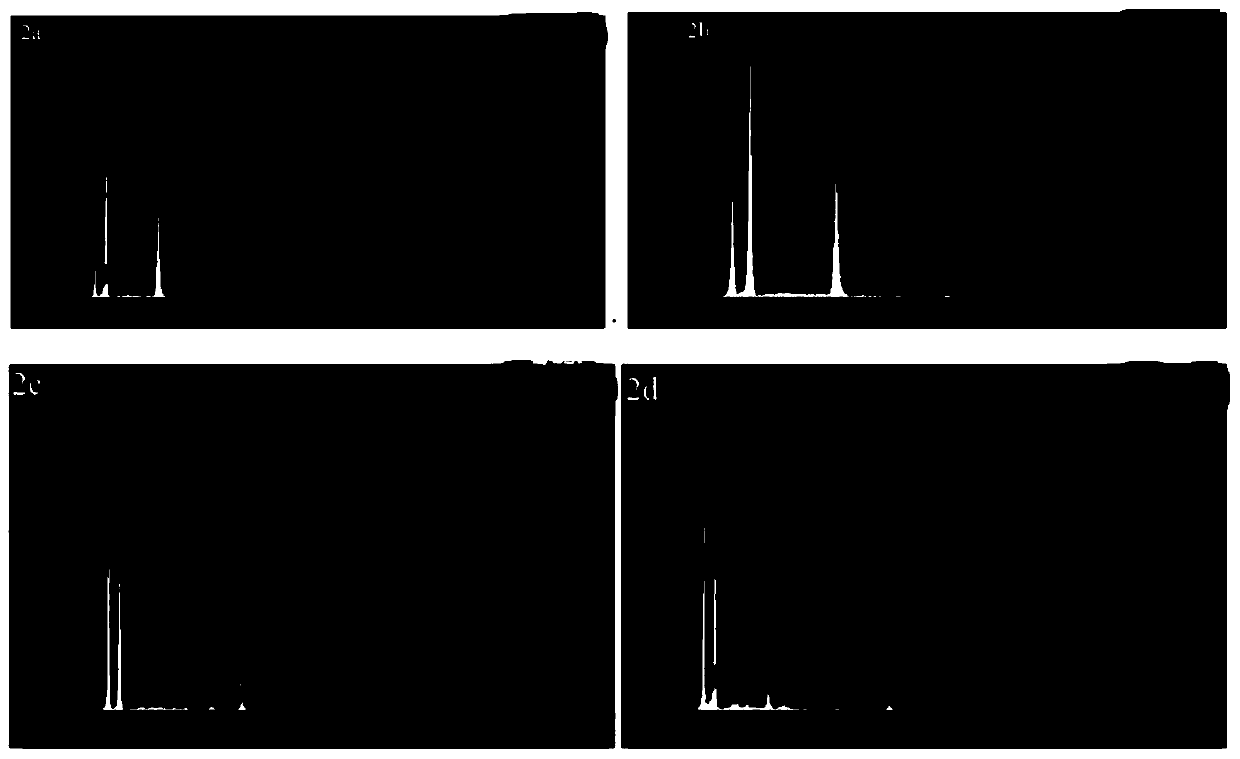

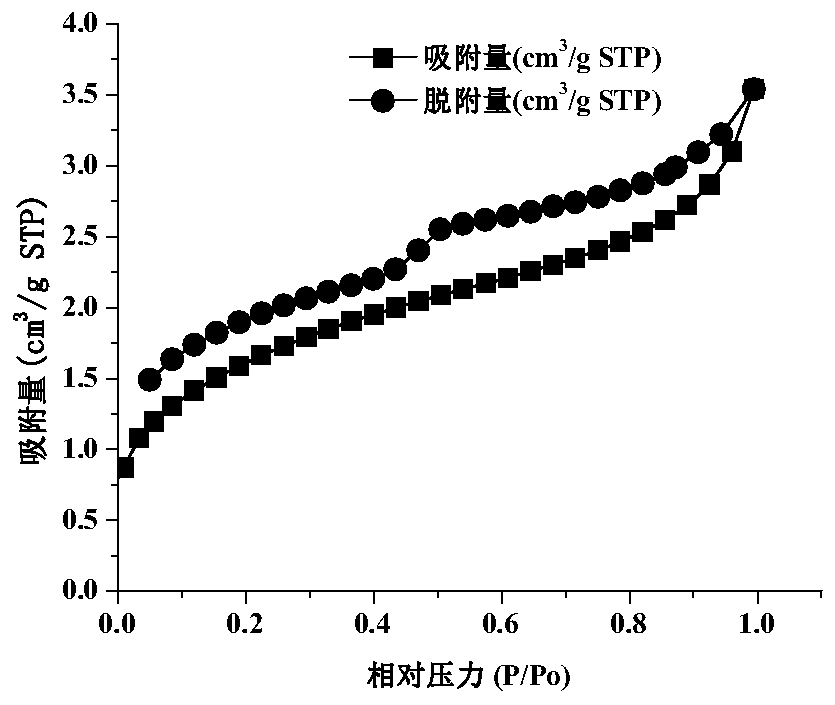

[0039] Characterize the RS-nHTO prepared by the above method:

[0040] (1) ...

Embodiment 2

[0049] The rice straw-loaded nano-hydrated titanium dioxide composite material prepared in Example 1 was used to photocatalytically degrade organic pollutants in water (represented by methylene blue), and it was investigated whether the pollutants could be degraded under the conditions of simulating sunlight and visible light.

[0050] (1) Investigation of the degradation efficiency of methylene blue by RS-nHTO with different power

[0051] Figure 5 With 0.1g RS-nHTO at 150W and 300W power, the composite material was subjected to photodegradation reaction to 10mg / L methylene blue, and was sampled and measured by spectrophotometry. From the obtained results, it can be clearly seen that with the increase of light source power , the photodegradation effect of the composite material on methylene blue showed a slight increase, and the methylene blue was almost completely removed in 150min.

[0052] (2) Determination of the efficiency of methylene blue degradation by RS-nHTO with ...

Embodiment 3

[0062] (1) Adopt the composite adsorbent material among the embodiment 1 to be used for Cu in water 2+ (concentration is 10mg / L) adsorption test:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com