Reusable substance amount sensor in prodn. of organic luminous device

An organic light-emitting device and sensor technology, which can be applied to measurement devices, lighting devices, electrical devices, etc., can solve problems such as the limitation of crystal substance mass sensors, and achieve the effect of an effective manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The term "substrate" herein refers to a light transmissive support on which are preformed a plurality of laterally spaced first electrodes (anodes), this substrate being the precursor to passive matrix OLEDs. The term "structure" here refers to the substrate after receiving a portion of the vapor-deposited organic layer, and indicates the difference between the active matrix arrangement and its passive matrix predecessor.

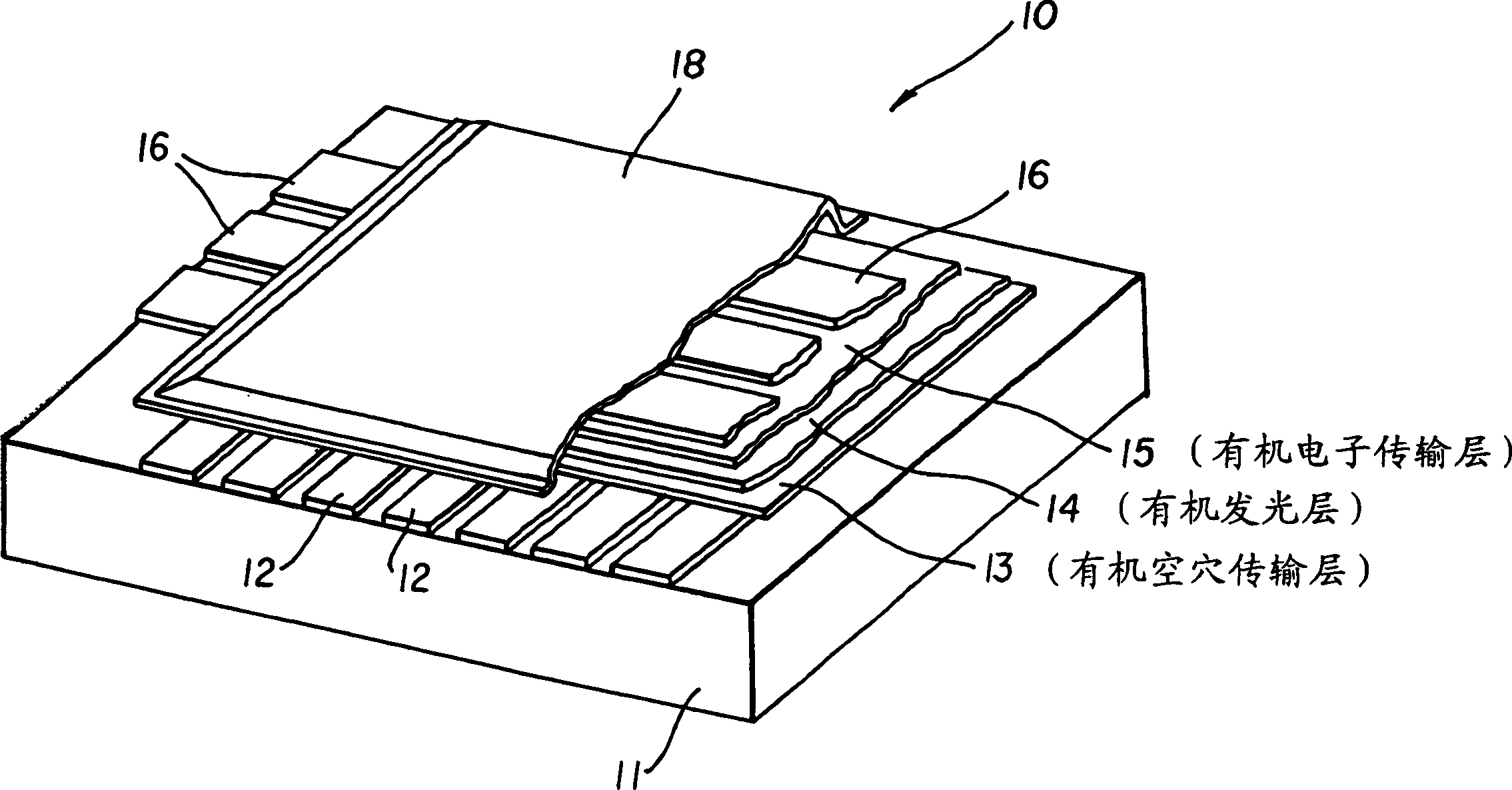

[0034] see figure 1 , figure 1 is a schematic perspective view showing a passive matrix organic light emitting device (OLED) 10 in which some elements have been peeled away to expose various layers.

[0035]A plurality of laterally spaced apart first electrodes 12 (also referred to as anodes) are formed on the light transmissive substrate 11 . An organic hole-transporting layer (HTL) 13 , an organic light-emitting layer (LEL) 14 and an organic electron-transporting layer (ETL) 15 are sequentially formed by physical vapor deposition, which will be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com