Silver nanowire array electrode and its preparation method and application

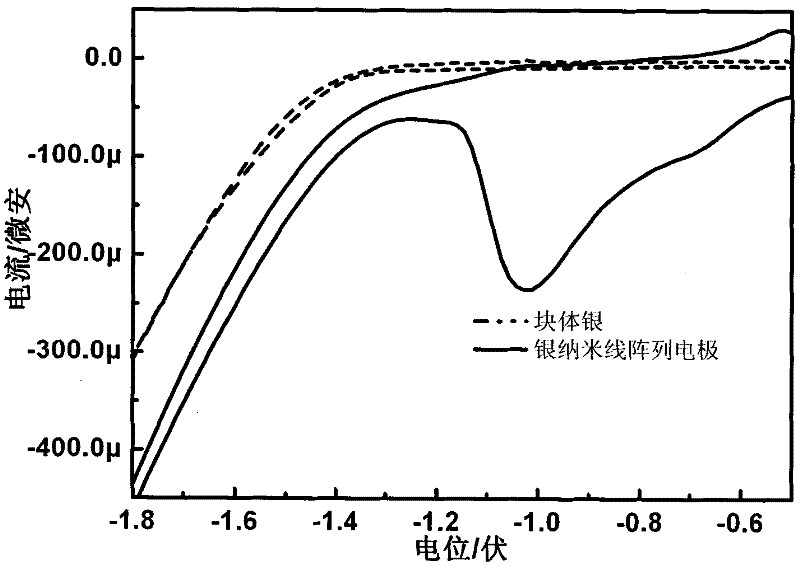

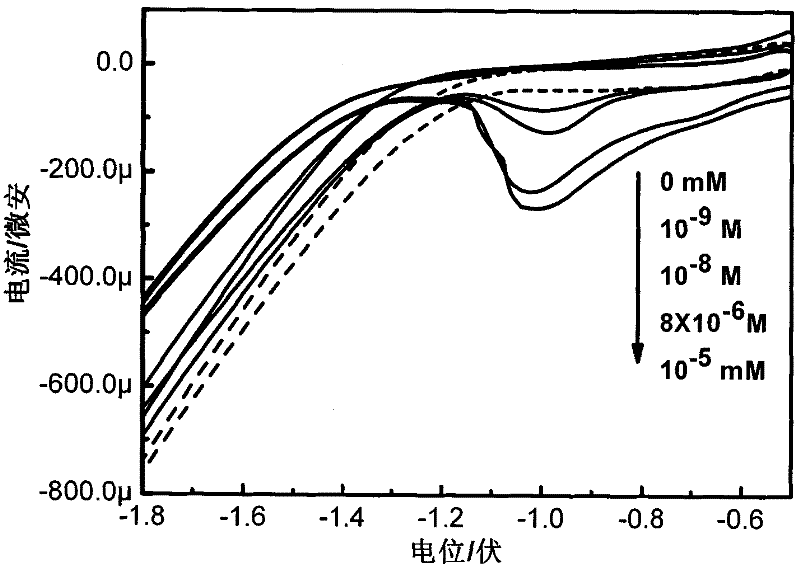

A technology of silver nanowires and array electrodes, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of low specific surface area, low adsorption and catalysis efficiency, restricting sensitivity and accuracy, etc., and achieves scientific preparation method. , Not easy to break, good array effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The concrete steps of preparation are:

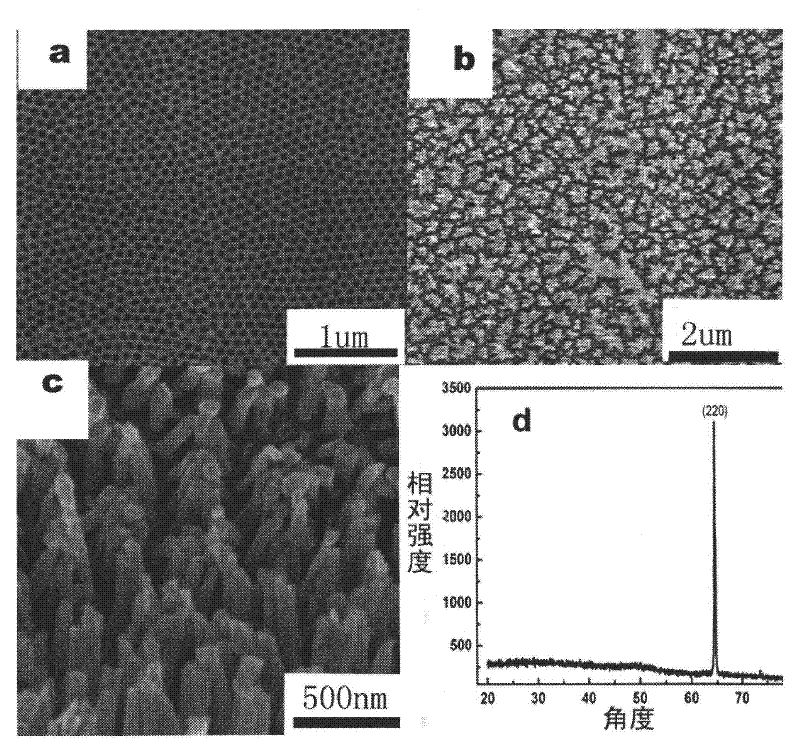

[0028] Step 1, first use the secondary anodic oxidation method on the aluminum sheet to obtain a through-hole alumina template with a pore diameter of 50nm, and then use the ion sputtering method to vapor-deposit a silver film on one side of the alumina template to obtain an oxide film with a silver film on one side. Aluminum formwork.

[0029] Step 2, first place the aluminum oxide template with a silver film on one side in the silver electrolyte, and use the electrodeposition method to electrodeposit at a constant voltage of 0.08V for 5 minutes; wherein, the silver electrolyte is 10g / L AgNO 3 and 30g / L of H 3 BO 3 of the mixture. Then put it in the copper electrolyte, use the electrodeposition method at 8mA / cm 2 3.5h of electrodeposition under the current; Among them, the copper electrolyte is 30g / L CuSO 4 and 60g / L of H 3 BO 3 of the mixture. An aluminum oxide template with silver nanowires placed in holes and one side...

Embodiment 2

[0032] The concrete steps of preparation are:

[0033] Step 1, first use the secondary anodic oxidation method on the aluminum sheet to obtain a through-hole alumina template with a pore diameter of 55nm, and then use the ion sputtering method to vapor-deposit a silver film on one side of the alumina template to obtain an oxide film with a silver film on one side. Aluminum formwork.

[0034] Step 2, first place the aluminum oxide template with a silver film on one side in the silver electrolyte, and use the electrodeposition method to electrodeposit at a constant voltage of 0.09V for 4 minutes; wherein, the silver electrolyte is 10g / L AgNO 3 and 30g / L of H 3 BO 3 of the mixture. Then put it in the copper electrolyte, use the electrodeposition method at 9mA / cm 2 3.3h of electrodeposition under the current; Among them, the copper electrolyte is 30g / L CuSO 4 and 60g / L of H 3 BO 3 of the mixture. An aluminum oxide template with silver nanowires placed in holes and one side...

Embodiment 3

[0037] The concrete steps of preparation are:

[0038] Step 1, first use the secondary anodic oxidation method on the aluminum sheet to obtain a through-hole alumina template with a hole diameter of 60nm, and then use the ion sputtering method to vapor-deposit a silver film on one side of the alumina template to obtain an oxide film with a silver film on one side. Aluminum formwork.

[0039] Step 2, first place the aluminum oxide template with a silver film on one side in the silver electrolyte, and use the electrodeposition method to electrodeposit at a constant voltage of 0.1V for 3 minutes; wherein, the silver electrolyte is 10g / L AgNO 3 and 30g / L of H 3 BO 3 of the mixture. Then put it in the copper electrolyte, use the electrodeposition method at 10mA / cm 2 Electrodeposition for 3h under the electric current; Among them, the copper electrolyte is 30g / L CuSO 4 and 60g / L of H 3 BO 3 of the mixture. An aluminum oxide template with silver nanowires placed in holes and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com