Preparation method and application of oxidation nitrogen-doped carbon nanotube array cluster/flexible carbon fiber material integrated electrode

A technology of carbon fiber materials and nanotube arrays, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, nanotechnology, battery electrodes, etc., can solve the problem of reducing the oxygen separation and dissociation energy barrier and the ineffectiveness of oxygen negative ions Obvious, poor battery cycle performance and other problems, to achieve the effect of improving charge-discharge cycle performance and improving bidirectional catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

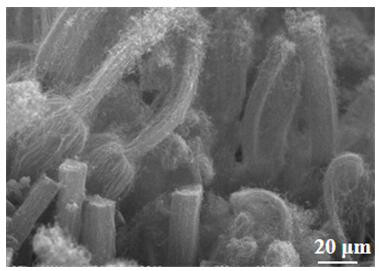

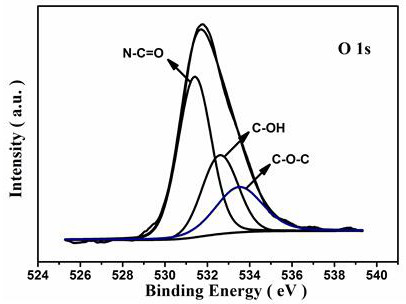

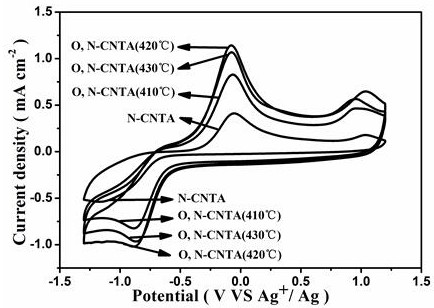

Image

Examples

Embodiment 1

[0038] (1) Preparation of conductive carbon black layer / carbon paper substrate

[0039] The carbon paper was cut into a size of 3 × 3 cm, dipped in isopropanol solvent, 80 Hz ultrasonic for 20 min to remove impurities on the surface of the carbon paper, and then taken out and dried for later use. Put 6.06 g of catalyst precursor ferric nitrate in the beaker, add 0.08 g of oxidized conductive carbon black and 15 g of 30% (mass fraction) acidic silica sol, and mechanically stir for 18 h at room temperature to make a stable suspension; Use a disposable dropper to drop a small amount of suspension on the surface of the surface-treated carbon paper, smear evenly, take it out after drying at a constant temperature, and then fill it according to the above-mentioned smearing method, and cycle 6 times; put the surface-filled carbon paper in the middle of the quartz tube , and then place the quartz tube in the constant temperature zone of the reaction tube furnace, in the air atmosphere...

Embodiment 2

[0050] (1) Preparation of conductive graphene layer / carbon cloth substrate

[0051]The carbon cloth was cut into a size of 4 × 4 cm and immersed in isopropanol solvent, and the impurities on the surface of the carbon paper were removed by ultrasonication at 60 Hz for 30 min, and then taken out and dried for later use. Put 7.04 g of catalyst precursor nickel nitrate in a beaker, add 0.12 g of oxidized graphene and 10 g of 40% (mass fraction) alkaline silica sol, and stir mechanically for 20 h at room temperature to make a stable suspension ; Use a disposable dropper to drop a small amount of suspension on the surface of the surface-treated carbon cloth, smear evenly, take it out after constant temperature drying, and then fill it according to the above-mentioned smearing method, and cycle 5 times; put the surface-filled carbon cloth in the middle of the quartz tube Cloth, and then place the quartz tube in the constant temperature area of the reaction tube furnace, in the air ...

Embodiment 3

[0057] (1) Preparation of conductive Ketjen black layer / carbon felt substrate

[0058] The carbon felt was cut into a size of 3 × 5 cm and immersed in isopropanol solvent, 80 Hz ultrasonic for 20 min to remove impurities on the surface of the carbon felt, and then taken out and dried for later use. Put 8.03 g of catalyst precursor cobalt nitrate into the beaker, add 0.1 g of oxidized Ketjen Black and 15 g of 50% (mass fraction) alkaline silica sol, and mechanically stir for 18 h at room temperature to form a stable suspension Drop a small amount of suspension on the surface of the surface-treated carbon felt with a disposable dropper, smear evenly, take it out after drying at a constant temperature, and then fill it according to the above-mentioned smearing method, and cycle 9 times; put the surface-filled surface in the middle of the quartz tube carbon felt, and then place the quartz tube in the constant temperature zone of the reaction tube furnace, under the air atmosphere,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com