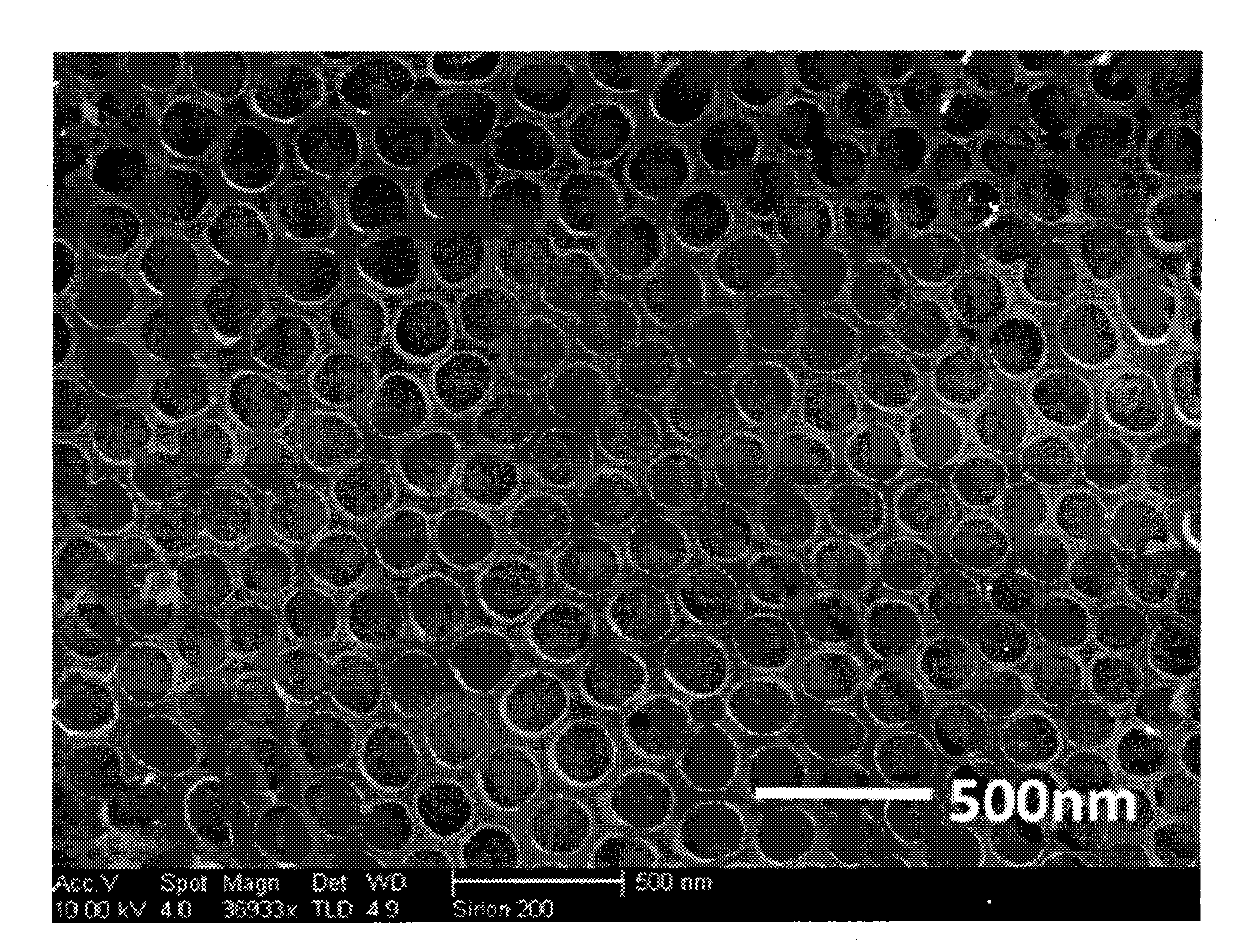

Preparation method of titanium dioxide nanopore array film

A technology of nanohole array and titanium dioxide, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult preparation and inability to obtain hole array film, and achieve the effect of scientific preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

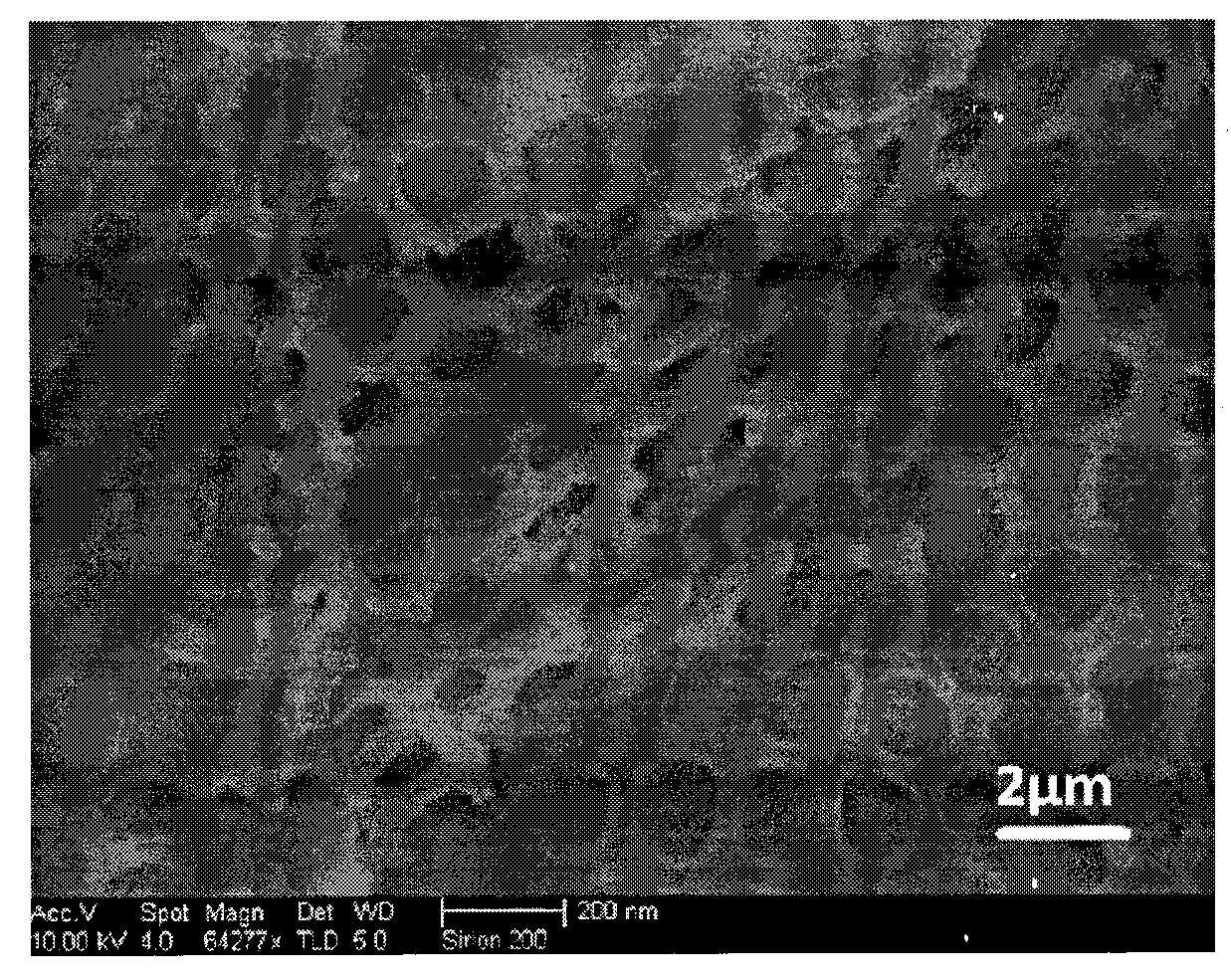

Image

Examples

Embodiment 1

[0020] The concrete steps of preparation are:

[0021] In step 1, ammonium fluoride, water and ethylene glycol are mixed in a mass ratio of 3:18:950 to obtain an electrolyte. Reuse oxidation area is 9.6cm 2 The electrolyte solution is oxidized by a two-electrode system with a titanium sheet as the anode and graphite as the cathode to obtain electrolyte solution 1 and electrolyte solution 2; wherein, the oxidation temperature of electrolyte solution 1 is 23°C, and the voltage is a constant voltage of 58V. The time is 4 hours, the oxidation temperature of the electrolyte 2 is 23°C, the voltage is 92s at 58V and 320s at 38V, and the time is 100 hours.

[0022] Step 2, first place the titanium sheet in the electrolyte solution 1 at 23°C, and oxidize it at a constant voltage of 58V for 1520s. Then it was placed in the electrolyte solution 2 at 23°C, and oxidized at a constant voltage of 58V for 1520s, 620s at a constant voltage of 38V, and 1820s at a constant voltage of 58V in se...

Embodiment 2

[0025] The concrete steps of preparation are:

[0026] In step 1, ammonium fluoride, water and ethylene glycol are first mixed according to a mass ratio of 3:19:960 to obtain an electrolyte. Reuse oxidation area is 9.7cm 2 The electrolyte solution is oxidized by a two-electrode system with titanium sheet as the anode and graphite as the cathode in / L to obtain electrolyte solution 1 and electrolyte solution 2; wherein, the oxidation temperature of electrolyte solution 1 is 24°C, and the voltage is a constant voltage of 59V, The time is 3.8 hours, the oxidation temperature of the electrolyte 2 is 24°C, the voltage is 91s at 59V and 310s at 39V, and the time is 110 hours.

[0027] Step 2, first place the titanium sheet in the electrolyte solution 1 at 24°C, and oxidize it at a constant voltage of 59V for 1510s. It was then placed in electrolyte solution 2 at 24°C, and oxidized at a constant voltage of 59V for 1510s, 610s at a constant voltage of 39V, and 1810s at a constant vo...

Embodiment 3

[0030] The concrete steps of preparation are:

[0031] In step 1, ammonium fluoride, water and ethylene glycol are mixed in a mass ratio of 3:20:970 to obtain an electrolyte. Reuse oxidation area is 9.8cm 2The electrolyte solution is oxidized by a two-electrode system with a titanium sheet as the anode and graphite as the cathode to obtain electrolyte solution 1 and electrolyte solution 2; wherein, the oxidation temperature of electrolyte solution 1 is 25°C, and the voltage is a constant voltage of 60V. The time is 3.5 hours, the oxidation temperature of the electrolyte 2 is 25° C., the voltage is 60 V for 90 s and 40 V for 300 s, and the time is 120 hours.

[0032] Step 2, first place the titanium sheet in the electrolyte solution 1 at 25°C, and oxidize it at a constant voltage of 60V for 1500s. Then it was placed in electrolyte solution 2 at 25°C, and oxidized at a constant voltage of 60V for 1500s, at a constant voltage of 40V for 600s, and at a constant voltage of 60V fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com