Ordered structure array of two-dimensional hollow balls and preparing method thereof

A technology of ordered structure and hollow spheres, applied in the direction of nanostructure manufacturing, microstructure technology, microstructure devices, etc., can solve the problems of not being able to obtain hollow spheres, limiting superior performance and unique uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

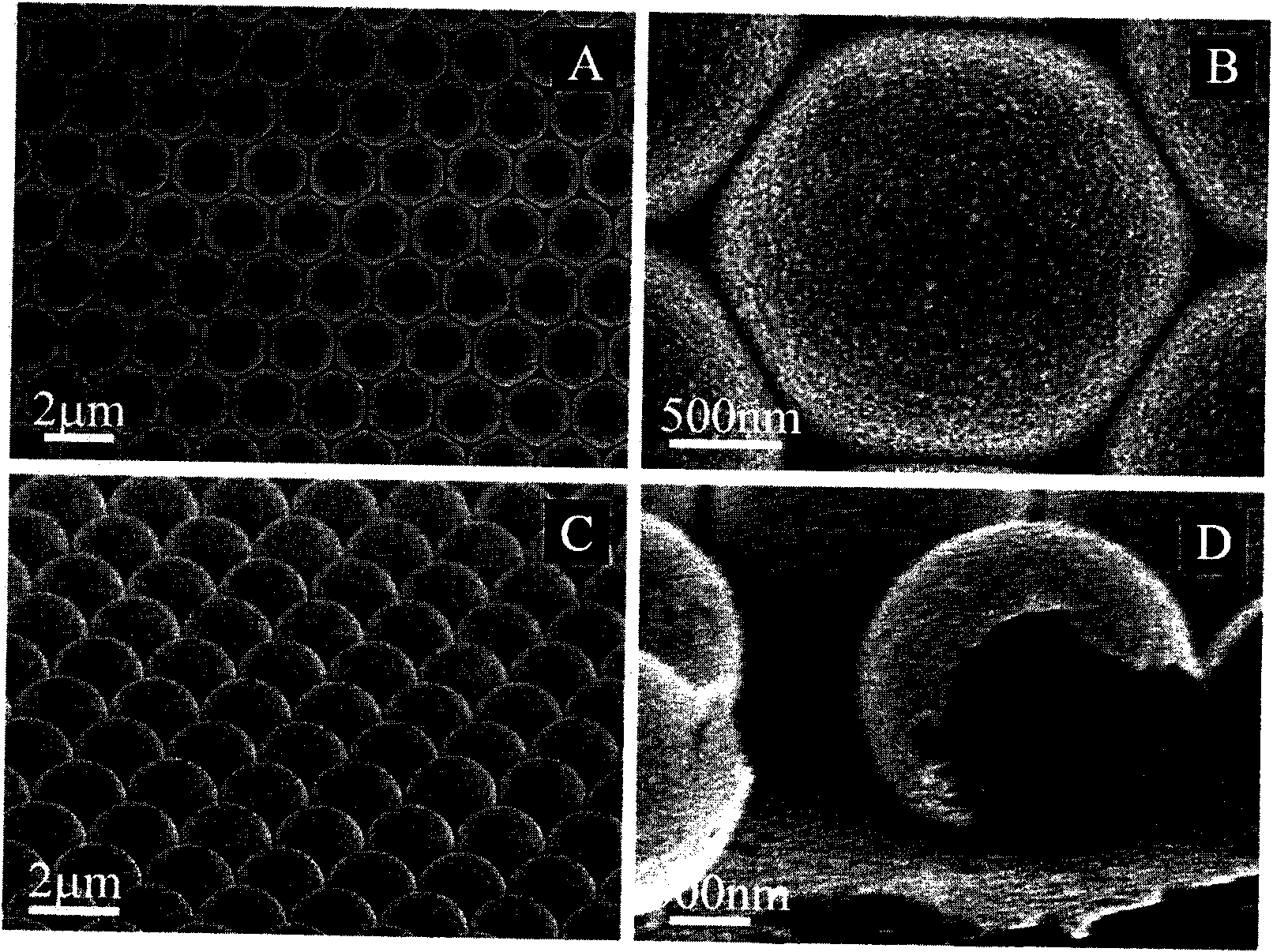

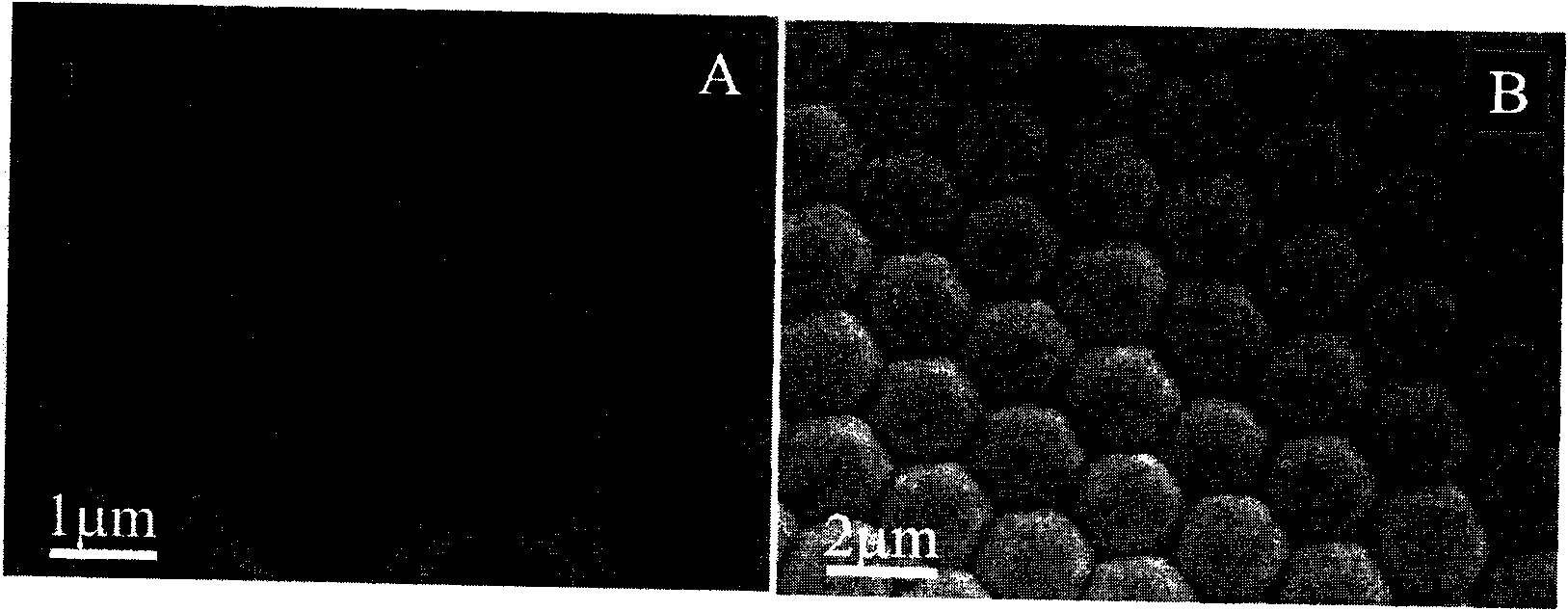

[0024] The concrete steps of preparation are:

[0025] Step 1, placing the conductive substrate with a single-layer colloidal crystal template made of polystyrene colloidal spheres with a diameter of 2000nm on it under a pressure of 5Pa, and depositing a layer of gold film with a thickness of 5nm by ion sputtering, A gold film wall array is obtained; wherein, the conductive substrate is conductive glass.

[0026] Step 2, first place the conductive substrate with the gold film wall array on it in the electrolyte solution at a temperature of 10°C, use it as a working electrode, and deposit it at a deposition current density of -1.0mA / cm 2 Next, the three-electrode method was used for electrodeposition for 10 seconds to obtain a composite array; wherein, the electrolyte was a metal gold electrolyte, the counter electrode was a graphite electrode during the three-electrode method electrodeposition, and the reference electrode was a saturated calomel electrode. Then the composite ...

Embodiment 2

[0029] The concrete steps of preparation are:

[0030] Step 1, placing the conductive substrate with a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 2000nm on it under a pressure of 6Pa, and depositing a layer of gold film with a thickness of 8nm by ion sputtering, A gold film wall array is obtained; wherein, the conductive substrate is conductive glass.

[0031] Step 2, first place the conductive substrate with the gold film wall array on it in the electrolyte solution at a temperature of 25°C, use it as a working electrode, and deposit it at a deposition current density of -0.4mA / cm 2 The complex array was obtained by using the three-electrode method for electrodeposition for 200 s. The electrolyte was a metal gold electrolyte, the counter electrode was a graphite electrode, and the reference electrode was a saturated calomel electrode. Then the composite array was placed in dichloromethane solvent to remove the polysty...

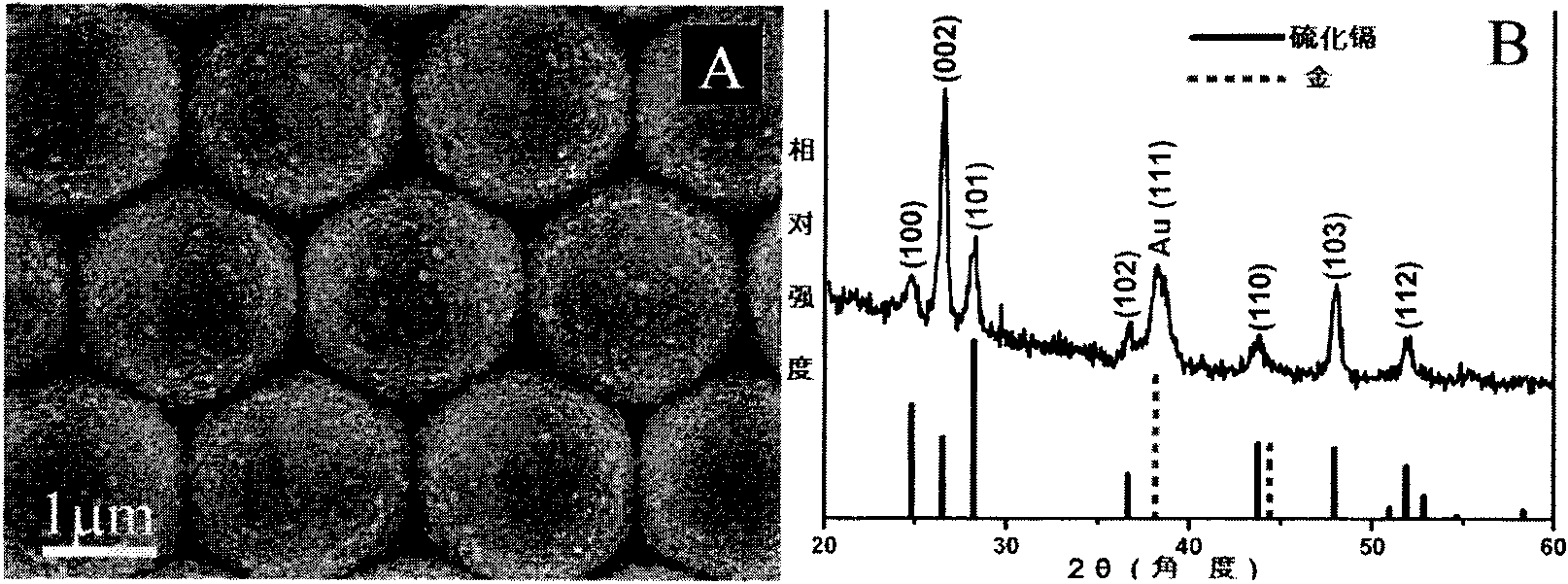

Embodiment 3

[0034] The concrete steps of preparation are:

[0035] Step 1, placing the conductive substrate with a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 2000nm on it under a pressure of 8Pa, and depositing a layer of gold film with a thickness of 10nm by ion sputtering, A gold film wall array is obtained; wherein, the conductive substrate is conductive glass.

[0036] Step 2, first place the conductive substrate with the gold film wall array on it in the electrolyte solution at a temperature of 50°C, use it as a working electrode, and deposit it at a deposition current density of -0.025mA / cm 2 The complex array was obtained by electrodeposition by three-electrode method for 30 minutes; the electrolyte was metal gold electrolyte, the counter electrode was graphite electrode and the reference electrode was saturated calomel electrode during electrodeposition by three-electrode method. Then the composite array was placed in dich...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com