Preparation method for nickel ferrite supercapacitor electrode material taking foamed nickel as substrate

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of difficulty in large-scale commercial application and expensive precious metals, and achieve good development prospects and preparation methods. Simple, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

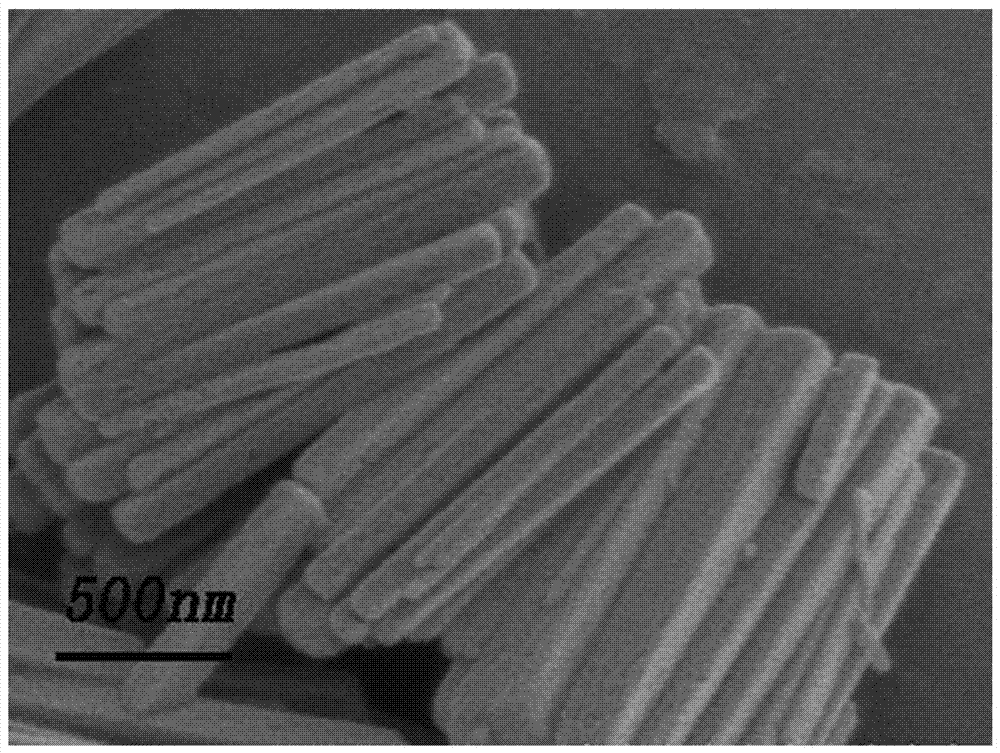

Embodiment 1

[0028] The nickel foam was ultrasonically cleaned with acetone, 1 M hydrochloric acid, ethanol and deionized water for 15 min, and then dried at 60 °С. Use 1 mM nickel chloride hexahydrate, 2 mM ferric chloride, 2 mM cetyltrimethylammonium bromide, 4.5 mM urea and 40mL water to prepare the precursor solution, stir at room temperature for 30 min to mix the precursor solution Evenly, put it into a stainless steel high-pressure reactor lined with polytetrafluoroethylene; put the dried nickel foam into the inner tank of the reactor, seal it, and place it in an oven at 100 °С for 16 h. After the reaction is completed, it will naturally After cooling to room temperature, the product was collected, washed several times with distilled water and ethanol, and dried at 60°С for 12 hours. The dried nickel foam was placed in a tube furnace and annealed at 350 °С in an air atmosphere for 2 hours to obtain a nickel ferrite supercapacitor electrode material based on nickel foam.

Embodiment 2

[0030] The nickel foam was ultrasonically cleaned with acetone, 1 M hydrochloric acid, ethanol and deionized water for 15 min, and then dried at 60 °С. Use 1 mM nickel chloride hexahydrate, 2 mM ferric chloride, 2 mM cetyltrimethylammonium bromide, 4.5 mM urea and 40mL water to prepare the precursor solution, stir at room temperature for 30 min to mix the precursor solution Uniformly, put the above precursor solution in the reactor liner made of polytetrafluoroethylene; put the dried nickel foam into the reactor liner, then seal it with a stainless steel high-pressure reactor, and place it in an oven at 110 °С After the reaction was completed, it was naturally cooled to room temperature, and the collected product was washed several times with distilled water and ethanol, respectively, and dried at 60°С for 12 hours. The dried nickel foam material was placed in a tube furnace and annealed at 350°С in an air atmosphere for 2 hours to obtain a nickel ferrite supercapacitor electr...

Embodiment 3

[0032] The nickel foam was ultrasonically cleaned with acetone, 1 M hydrochloric acid, ethanol and deionized water for 15 min, and then dried at 60 °С. Use 1 mM nickel chloride hexahydrate, 2 mM ferric chloride, 2 mM cetyltrimethylammonium bromide, 4.5 mM urea and 40mL water to prepare the precursor solution, stir at room temperature for 30 min to mix the precursor solution Uniformly, put the above precursor solution in the reactor liner made of polytetrafluoroethylene; put the dried nickel foam into the reactor liner, then seal it with a stainless steel reactor, and place it in an oven at 120 °С Reacted for 16 h, cooled naturally to room temperature after the reaction was completed, collected products were washed several times with distilled water and ethanol, and dried at 60 °С for 12 h. The dried nickel foam material was placed in a tube furnace and annealed at 350 °С in an air atmosphere for 2 hours to obtain a nickel ferrite nanostructure supercapacitor electrode material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com