Nanometer fire retardant coating and preparation method thereof

A kind of fireproof coating, nanotechnology, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of too little addition, reduced fireproof efficiency, unreasonable formula components, etc., and achieve the effect of scientific preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

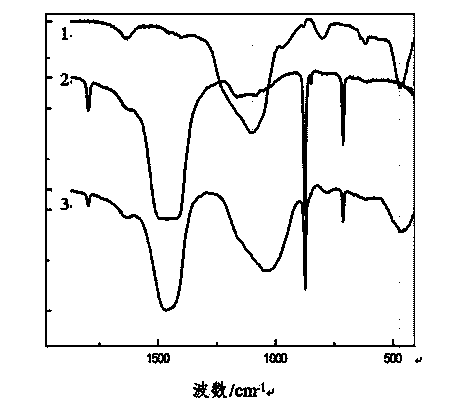

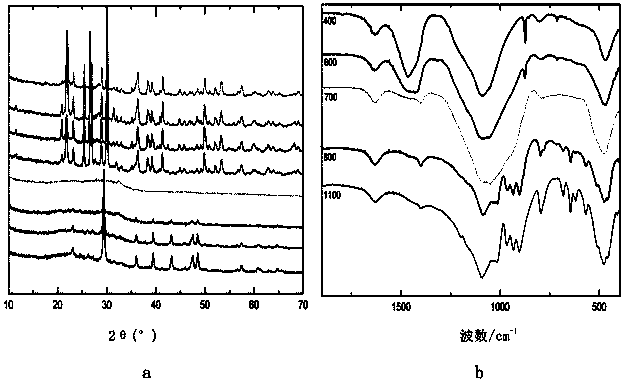

Image

Examples

Embodiment 1

[0030] The specific steps of preparation are:

[0031] Step 1. Firstly, the inorganic nanoparticles are added to the 10wt% sodium silicate aqueous solution to ultrasonically disperse for 10 minutes and then stirred for 2 hours to obtain a mixed solution; wherein the inorganic nanoparticles are calcium carbonate. Then the mixed solution under stirring was adjusted to pH 5 with acid at 75° C., and then aged for 4 hours to obtain a mixed sol; wherein the acid was hydrochloric acid.

[0032] In step 2, the mixed sol is suction filtered and washed three times, and then dried at 120° C. for 12 hours to obtain composite particles. Then, the composite particles and the silane coupling agent were added to ethanol at 130°C under stirring and refluxed for 60 minutes to obtain a reaction solution; wherein the weight ratio of ethanol, composite particles and silane coupling agent in the reaction solution was 75: 22:1.

[0033] Step 3. After the reaction solution is washed and separated alternat...

Embodiment 2

[0035] The specific steps of preparation are:

[0036] In step 1, firstly, the inorganic nanoparticles are added to a 20wt% sodium silicate aqueous solution to be ultrasonically dispersed for 15 minutes and then stirred for 2.5 hours to obtain a mixed solution; wherein the inorganic nanoparticles are calcium carbonate. Then, the mixed solution under stirring was adjusted to pH 6 with acid at 78° C., and then aged for 4.3 hours to obtain a mixed sol; wherein the acid was hydrochloric acid.

[0037] In step 2, the mixed sol is suction filtered and washed three times, and then dried at 125° C. for 11 hours to obtain composite particles. Then, the composite particles and the silane coupling agent were added to ethanol at a temperature of 133°C under stirring and refluxed for 50 minutes to obtain a reaction solution; wherein the weight ratio of ethanol, composite particles and silane coupling agent in the reaction solution was 78: 21:1.

[0038] Step 3. First, the reaction solution is w...

Embodiment 3

[0040] The specific steps of preparation are:

[0041] Step 1. Firstly, the inorganic nanoparticles are added to a 35wt% sodium silicate aqueous solution and ultrasonically dispersed for 20 minutes and then stirred for 3 hours to obtain a mixed solution; wherein the inorganic nanoparticles are calcium carbonate. Then, the mixed solution under stirring was adjusted to pH 7.5 with acid at 80° C., and then aged for 4.5 hours to obtain a mixed sol; wherein the acid was hydrochloric acid.

[0042] In step 2, the mixed sol was filtered and washed four times with suction, and then dried at 130°C for 10 hours to obtain composite particles. Then, the composite particles and the silane coupling agent were added to ethanol at a temperature of 135°C under stirring and refluxed for 45 minutes to obtain a reaction solution; wherein the weight ratio of ethanol, composite particles and silane coupling agent in the reaction solution was 80: 20:1.

[0043] Step 3: After the reaction solution is wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com