Method for producing optical film, optical film and image display device

A manufacturing method and technology of optical film, applied in chemical instruments and methods, optics, lamination devices, etc., can solve problems such as residues and appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

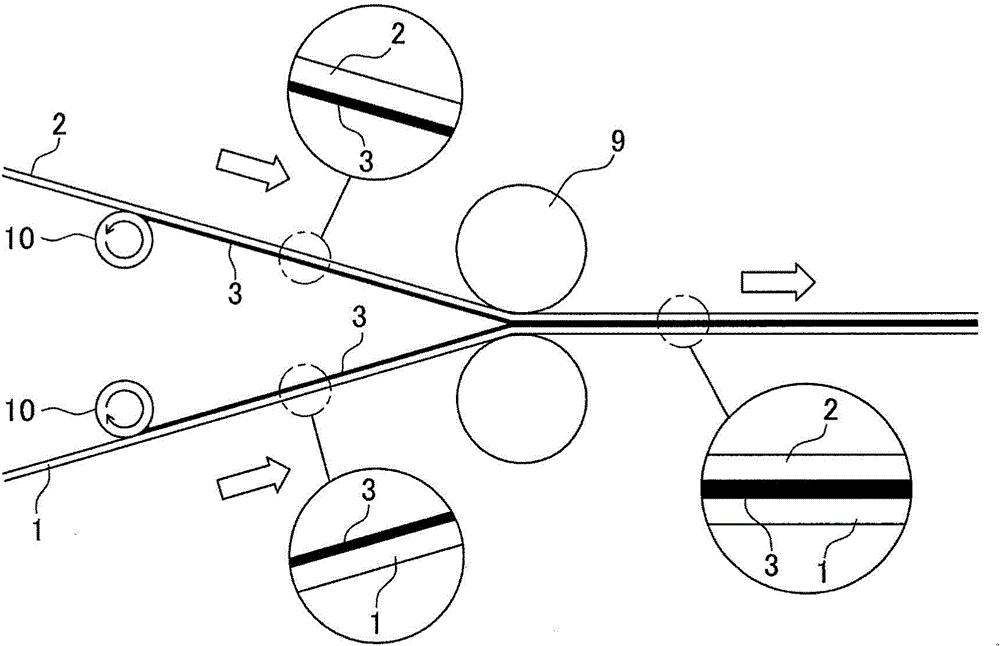

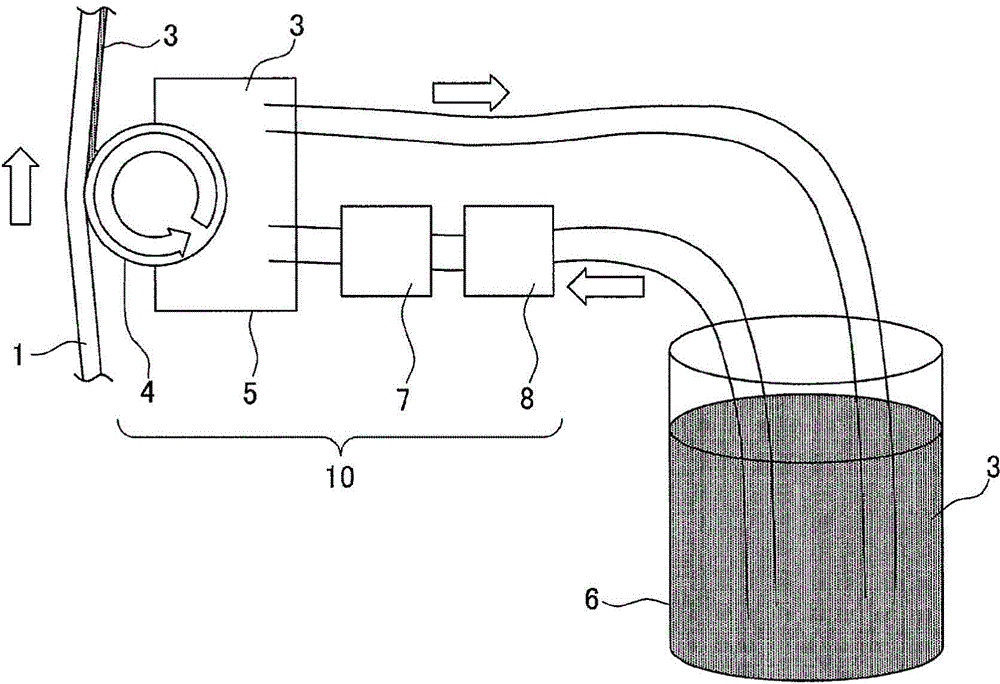

[0110] exist figure 1 , 2 In the production line shown, a gravure roll coating method 10 (MCD coater (manufactured by Fuji Machinery Co., Ltd.)) (cell shape: honeycomb pattern, gravure roll unit line number: 1000 lines / inch, rotating speed ratio 140%), the adhesive composition 3 was applied to both the bonding surface of the first film 1 and the bonding surface of the second film 2, whereby a polarizing film was produced while removing foreign substances and air bubbles. For the second film 2 composed of a PET base material and a thin polarizer, the adhesive composition 3 is coated with the thin polarizer surface as the bonding surface. It should be noted that the adhesive composition 3 has the thickness of the adhesive layer after drying Coated on the first film and the second film in a method of 1 μm. As the gravure roll coating method 10, use figure 2 Shown is a gravure roll coating system with a foreign matter removal function (foreign matter removal method using a filt...

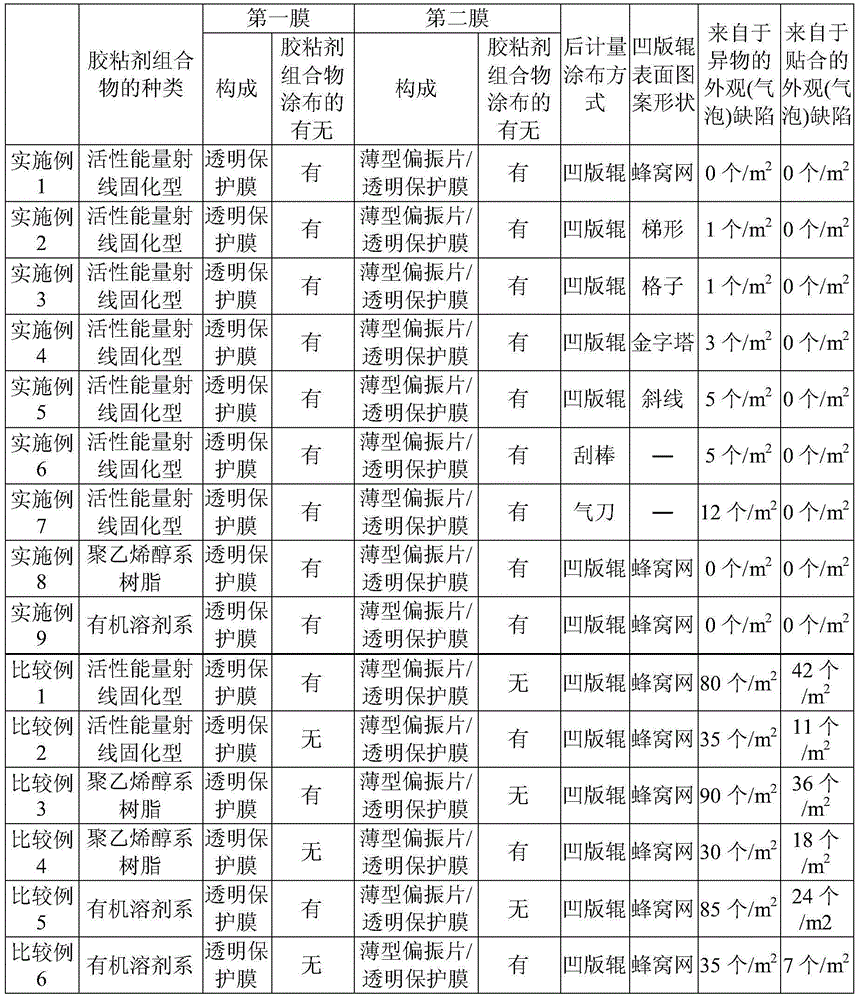

Embodiment 2~9、 comparative example 1~6

[0114] In addition to the type of adhesive composition used to bond the first film and the second film, whether the adhesive composition is applied to the first film and / or the second film, the type of post-measurement coating method, and the surface of the gravure roll Except having changed the formation pattern to the description of Table 1, the optical film was manufactured by the method similar to Example 1. In the bar coater coating system and the air knife coating system, a commercially available coating device was used, respectively.

[0115]

[0116] By visual inspection and reflective inspection with an automatic inspection device, the number of appearance defects in the adhesive layer of the polarizing film (the number of appearance defects from foreign matter and from (bonded) air bubbles (pieces / m 2 )). The results are shown in Table 1.

[0117] Table 1

[0118]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com