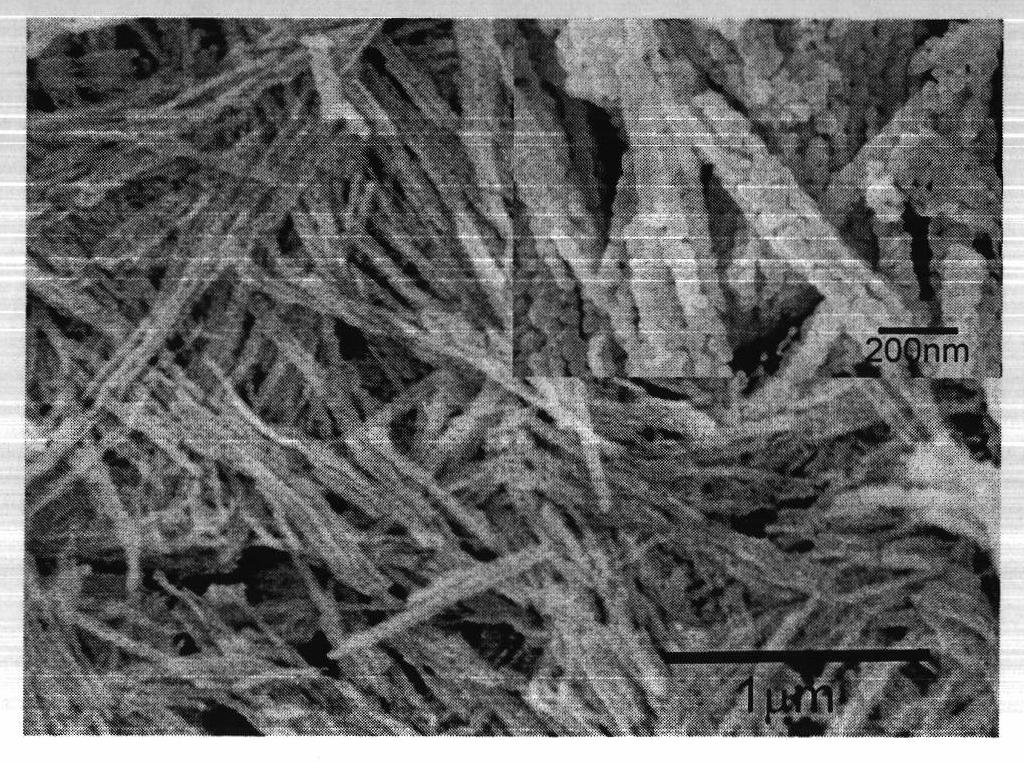

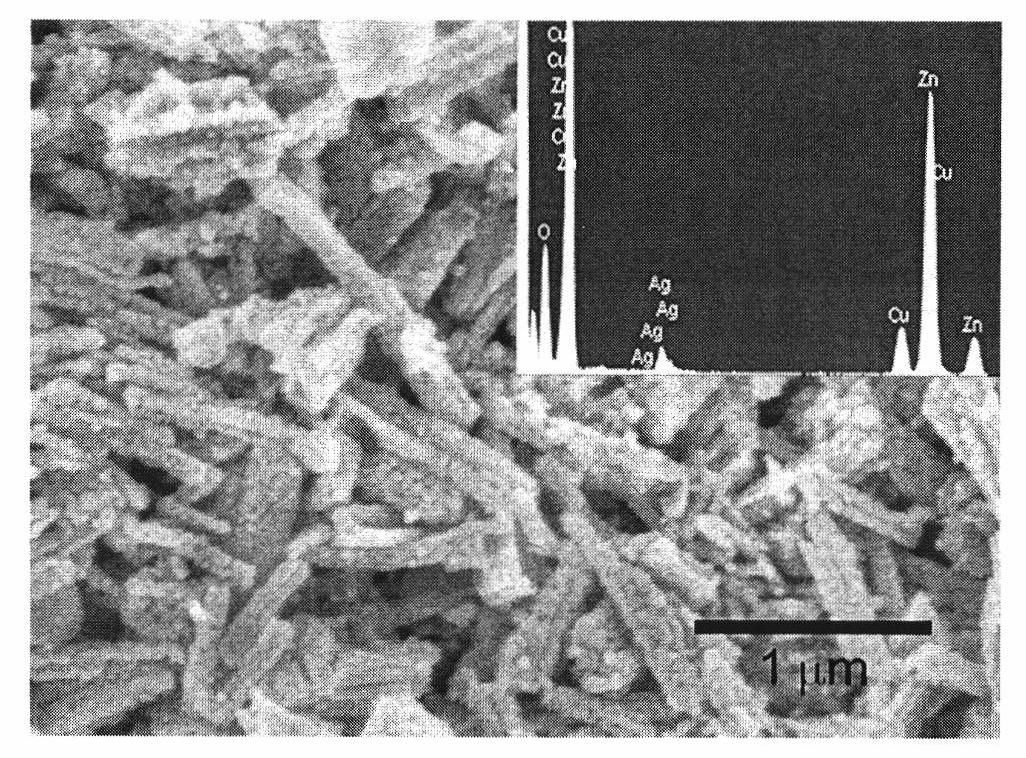

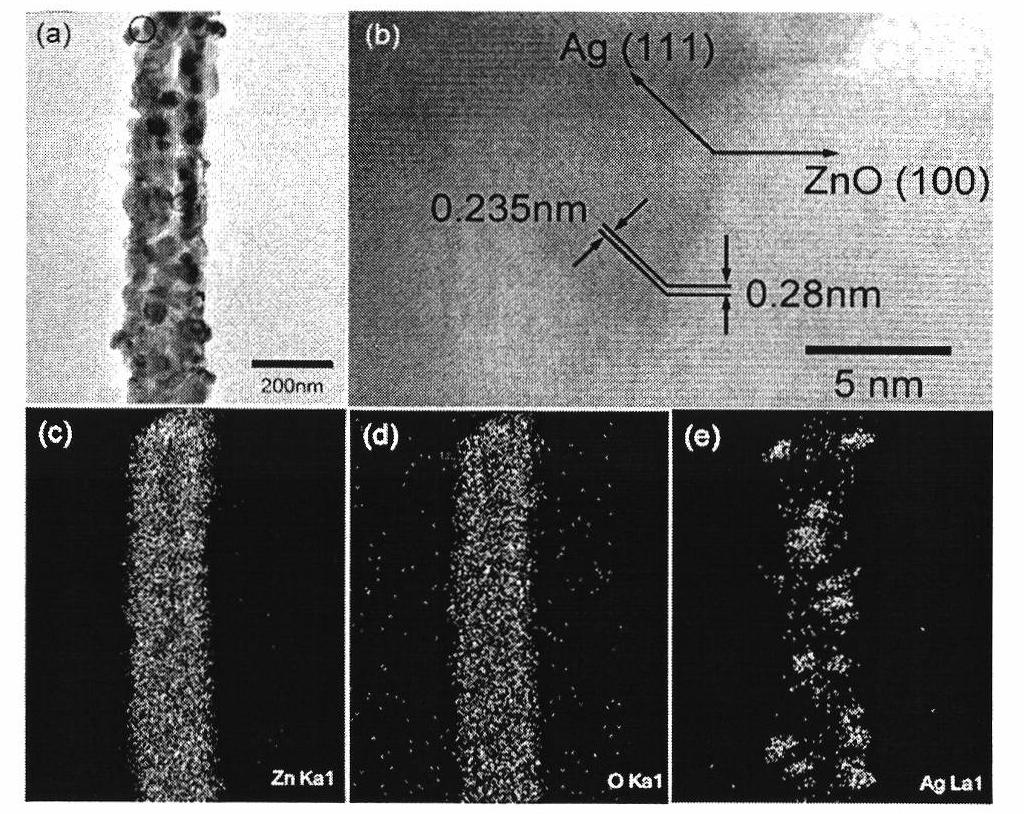

Porous zinc oxide-silver composite nanorod, as well as preparation method and application thereof

A technology of porous zinc oxide and zinc oxide, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. problem, to achieve good visible light catalytic degradation effect, scientific preparation method, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The concrete steps of preparation are:

[0035] Step 1, firstly mix zinc acetate ethanol solution and oxalic acid dihydrate ethanol solution with a molar ratio of 0.8:1.2, both of which have a concentration of 0.5M, to obtain a mixed solution. Then the mixed solution was placed in a closed state, and kept at a temperature of 70° C. for 7 hours to obtain an intermediate product of zinc oxide.

[0036] Step 2, the intermediate product of zinc oxide is first centrifuged, washed and dried to obtain zinc oxalate; wherein, the speed of centrifugal treatment of the intermediate product of zinc oxide is 6000r / min, the time is 3min, and the washing process is alternately using deionized Water and ethanol repeatedly wash the powdery zinc oxide intermediate product obtained after centrifugation until the washing solution becomes neutral, and the zinc oxide intermediate product is dried at 55° C. for 1.2 hours after centrifugation and washing. Zinc oxalate was annealed at 430° C. ...

Embodiment 2

[0039] The concrete steps of preparation are:

[0040] Step 1, firstly mix zinc acetate ethanol solution and oxalic acid dihydrate ethanol solution with a molar ratio of 0.9:1.1, both of which have a concentration of 0.6M, to obtain a mixed solution. Then the mixed solution was placed in a closed state, and kept at a temperature of 75° C. for 6.5 hours to obtain an intermediate product of zinc oxide.

[0041] Step 2, the zinc oxide intermediate product is first centrifuged, washed and dried to obtain zinc oxalate; wherein, the zinc oxide intermediate product is centrifuged at a speed of 6500r / min and the time is 2.5min, and the washing process is used alternately to remove The powdered zinc oxide intermediate product obtained after the centrifugation treatment was repeatedly washed with ionized water and ethanol until the washing liquid was neutral, and the zinc oxide intermediate product was dried at 58° C. for 1.2 hours after centrifugation and washing. Zinc oxalate was ann...

Embodiment 3

[0044] The concrete steps of preparation are:

[0045] Step 1: firstly mix zinc acetate ethanol solution and oxalic acid dihydrate ethanol solution with a molar ratio of 1:1 to obtain a mixed solution. Then the mixed solution was placed in a closed state, and kept at a temperature of 80° C. for 6 hours to obtain an intermediate product of zinc oxide.

[0046] Step 2, the intermediate product of zinc oxide is first centrifuged, washed and dried to obtain zinc oxalate; wherein, the intermediate product of zinc oxide is centrifuged at a speed of 7000r / min and the time is 2min, and the washing process is alternately using deionized Water and ethanol repeatedly wash the powdery zinc oxide intermediate product obtained after centrifugation until the washing solution is neutral, and the zinc oxide intermediate product is dried at 60° C. for 1.1 h after centrifugation and washing. Zinc oxalate was annealed at 450° C. for 2.5 hours, and then cooled to room temperature naturally to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com