Film formed by silver nanosheets and preparation method and application of film

A technology of silver nanosheets and nanosheets, which is applied in the field of thin films composed of silver nanosheets and its preparation, can solve the problems such as the preparation method does not disclose the composition of the electrolyte, the silver nanosheets have no morphology and size, and the final product cannot be obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

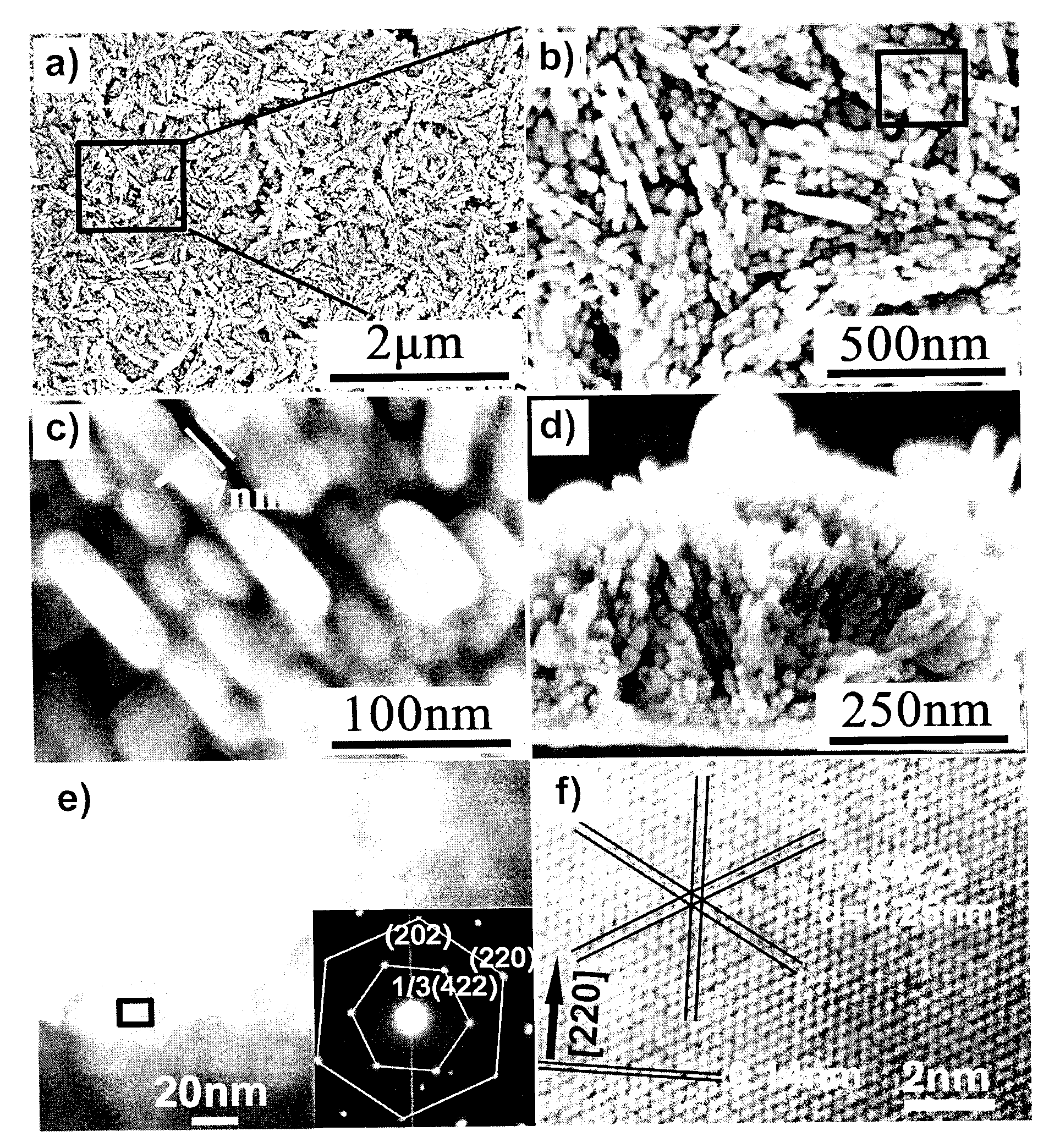

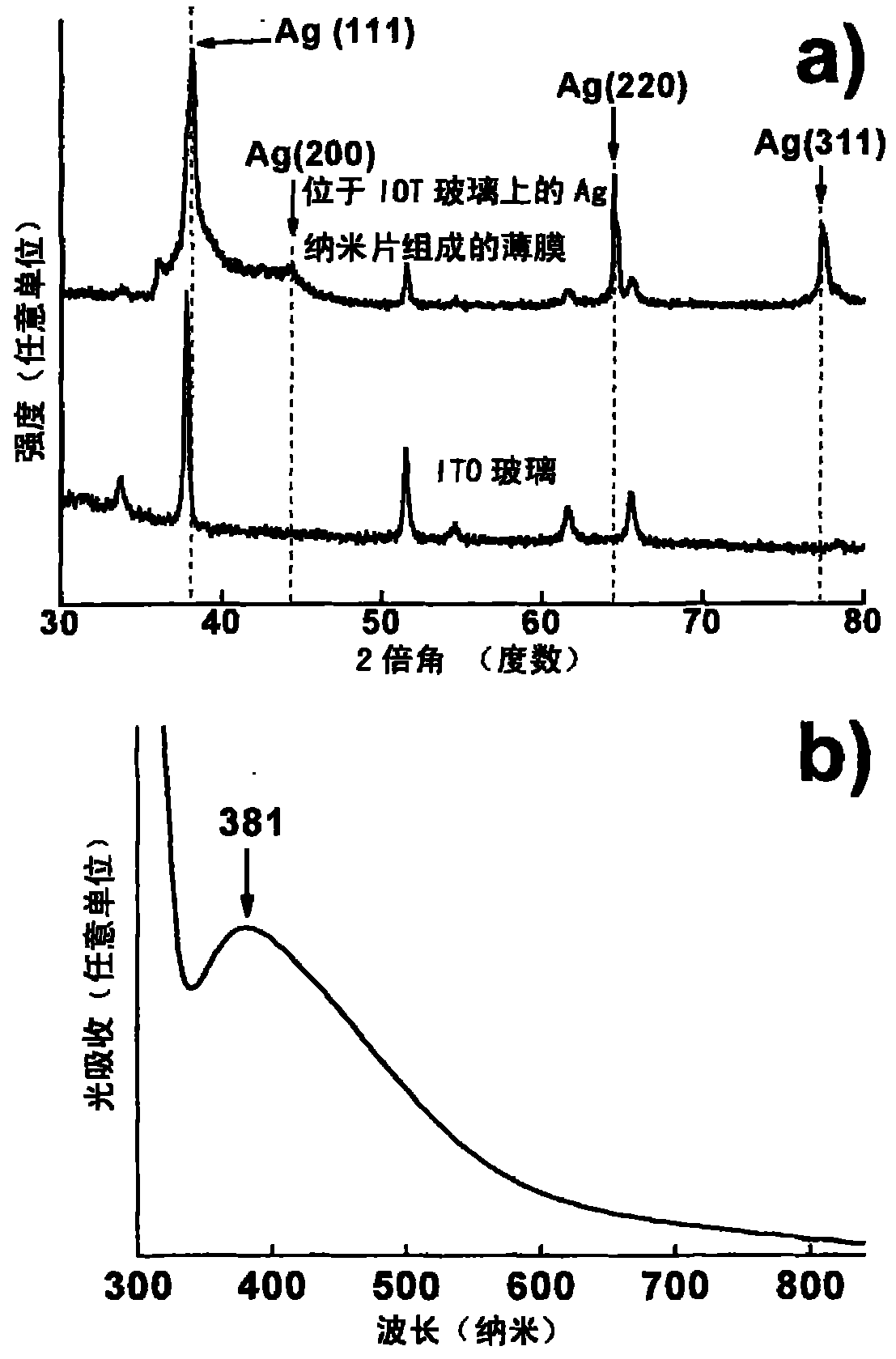

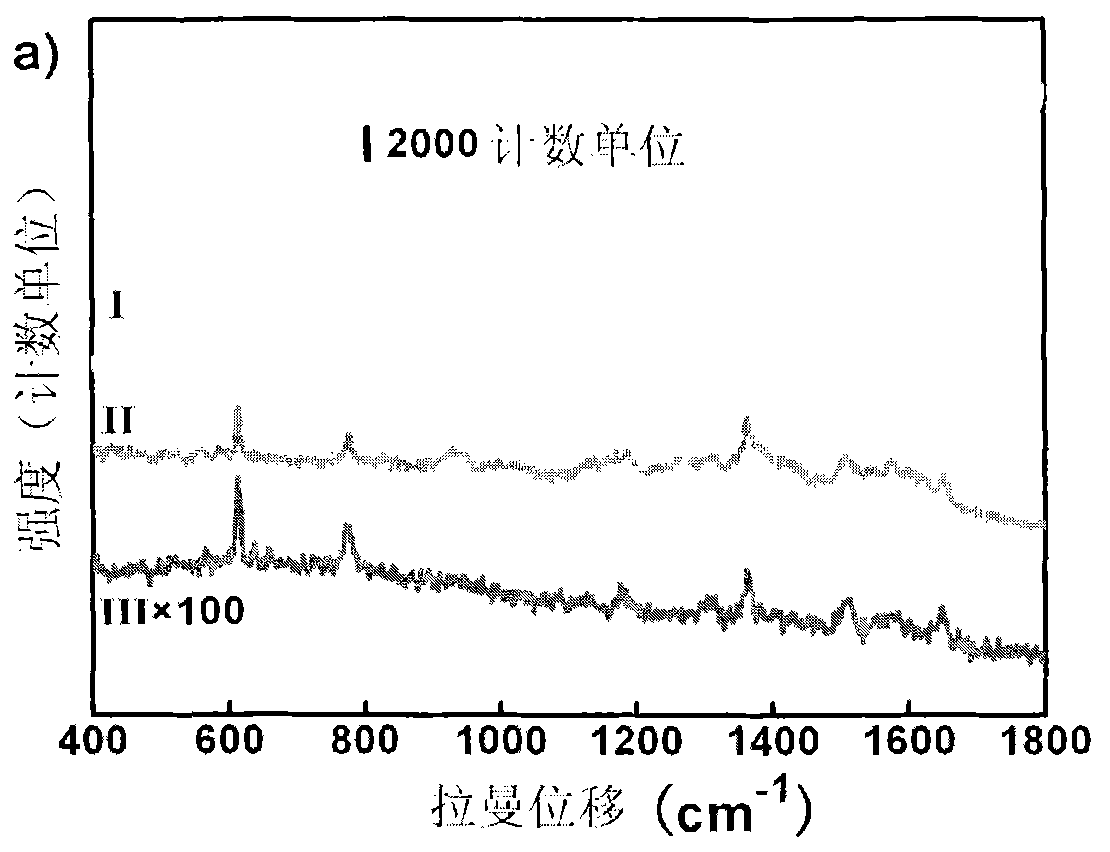

[0031] The concrete steps of preparation are:

[0032] Step 1, the silver nitrate aqueous solution that concentration is 8g / L, the citric acid aqueous solution that concentration is 6g / L and water are mixed according to the ratio of 1.8:1.1:96 according to the volume ratio and then stirred for 2min; Wherein, water is deionized water, to obtain a mixture. Then inject a sodium borohydride aqueous solution with a concentration of 0.7g / L into the mixed solution and stir for 10 minutes, then age at room temperature for 20 hours to obtain a silver crystal solution; wherein, the silver nitrate aqueous solution and the sodium borohydride aqueous solution in the silver crystal solution are The volume ratio between them is 1.1:0.9.

[0033] Step 2, after first coating the silver crystal solution on the conductive substrate, place it at 35°C to evaporate the water in the solution; wherein, the coating is spin coating (or spray coating, or dipping), and the conductive substrate is conduc...

Embodiment 2

[0035] The concrete steps of preparation are:

[0036] Step 1, first mix the aqueous solution of silver nitrate with a concentration of 9g / L, the aqueous solution of citric acid with a concentration of 6.5g / L and water according to the volume ratio of 1.9:1.05:97 and stir for 3 minutes; wherein, the water is deionized water , to obtain a mixture. Then inject a sodium borohydride aqueous solution with a concentration of 0.75g / L into the mixed solution and stir for 11 minutes, then age at room temperature for 20.5 hours to obtain a silver crystal solution; wherein, the silver nitrate aqueous solution and sodium borohydride in the silver crystal solution The volume ratio between the aqueous solutions is 1.05:0.95.

[0037] Step 2, after first coating the silver crystal solution on the conductive substrate, place it at 38°C to evaporate the water in the solution; wherein, the coating is spin coating (or spray coating, or dipping), and the conductive substrate is conductive glass...

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1, the silver nitrate aqueous solution that concentration is 10g / L, the citric acid aqueous solution that concentration is 7g / L and water are mixed according to the ratio of 2:1:98 according to the volume ratio and then stirred for 4min; Wherein, water is deionized water, to obtain a mixture. Then inject a sodium borohydride aqueous solution with a concentration of 0.8g / L into the mixed solution and stir for 12 minutes, then age at room temperature for 21 hours to obtain a silver crystal solution; wherein, the silver nitrate aqueous solution and the sodium borohydride aqueous solution in the silver crystal solution are The volume ratio between them is 1:1.

[0041] Step 2, after first coating the silver crystal solution on the conductive substrate, place it at 40°C to evaporate the water in the solution; wherein, the coating is spin coating (or spray coating, or dipping), and the conductive substrate is conductive g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com