Denitrification catalyst regeneration method

A denitrification catalyst and catalyst technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large catalyst hardness damage, catalyst breakage and cracks, insufficient ultrasonic power, etc., to achieve Improved pore structure and surface area, high cleaning efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Take the test module (53mm×53mm×300mm) of waste denitration catalyst from the power plant and test the denitration efficiency of the denitration catalyst under simulated flue gas conditions, which is 47%.

[0020] 2. Completely immerse the denitrification catalyst test module in the cleaning pool containing 0.5% dilute sulfuric acid, turn on the ultrasonic generator, take out the catalyst module after immersion for 30 minutes, and soak it in deionized water for 30 minutes.

[0021] 3. Dry the obtained catalyst in an oven at 260° C. for 3 hours, and ensure that the moisture in the oven is removed in time, and complete the catalyst regeneration process after cooling.

[0022] 4. The denitrification efficiency of the catalyst was tested under simulated flue gas conditions to be 57.6%.

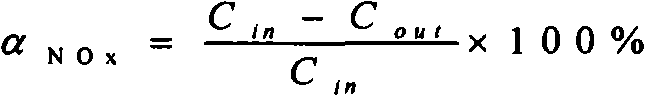

[0023] Catalyst activity test conditions: set up an experimental platform, put the catalyst in a fixed tubular heater, and inject simulated flue gas (SO 2 =800ppm, NOx=NH 3 =600ppm, O ...

Embodiment 2

[0028] 1. Prepare an ammonium carbonate cleaning solution with a mass fraction of 1%.

[0029] 2. The test module (53mm×53mm×300mm) of the waste denitrification catalyst of the power plant was intercepted, and the denitrification efficiency of the denitrification catalyst was tested under the simulated flue gas condition to be 47%.

[0030] 3. Completely immerse the denitrification catalyst test module in the cleaning tank containing 1% ammonium carbonate cleaning solution by mass fraction, stagnate for 30 minutes, transfer to the cleaning tank containing deionized water and immerse for 30 minutes.

[0031] 4. Dry the obtained catalyst in an oven at 260° C. for 3 hours, and ensure that the moisture in the oven is removed in time, and complete the catalyst regeneration process after cooling.

[0032] 5. The denitrification efficiency of the catalyst was tested under simulated flue gas conditions to be 68%.

[0033] Catalyst activity test condition is the same as embodiment 1. ...

Embodiment 3

[0035] 1. Prepare an ammonium carbonate cleaning solution with a mass fraction of 2%.

[0036] 2. The test module (53mm×53mm×300mm) of the waste denitrification catalyst of the power plant was intercepted, and the denitrification efficiency of the denitrification catalyst was tested under the simulated flue gas condition to be 47%.

[0037] 3. Completely immerse the denitrification catalyst test module in the cleaning tank containing 2% ammonium carbonate cleaning solution by mass fraction, stagnate for 30 minutes, transfer to the cleaning tank containing deionized water and immerse for 30 minutes.

[0038] 4. Dry the obtained catalyst in an oven at 240-320°C for 3 hours, and ensure that the moisture in the oven is removed in time, and complete the catalyst regeneration process after cooling.

[0039] 5. The catalyst denitrification efficiency is 71.3% under simulated flue gas conditions.

[0040] Catalyst activity test condition is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com