Preparation method of superfine yttrium oxide doped tungsten composite precursor powder

A technology of precursor powder and yttrium oxide, applied in chemical instruments and methods, rare earth metal compounds, rare earth metal oxides/hydroxides, etc., can solve the problem of weakening, uneven particle size of the second phase, and inability to disperse well Distribution and other issues, to achieve the effect of uniformity improvement, grain size refinement, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

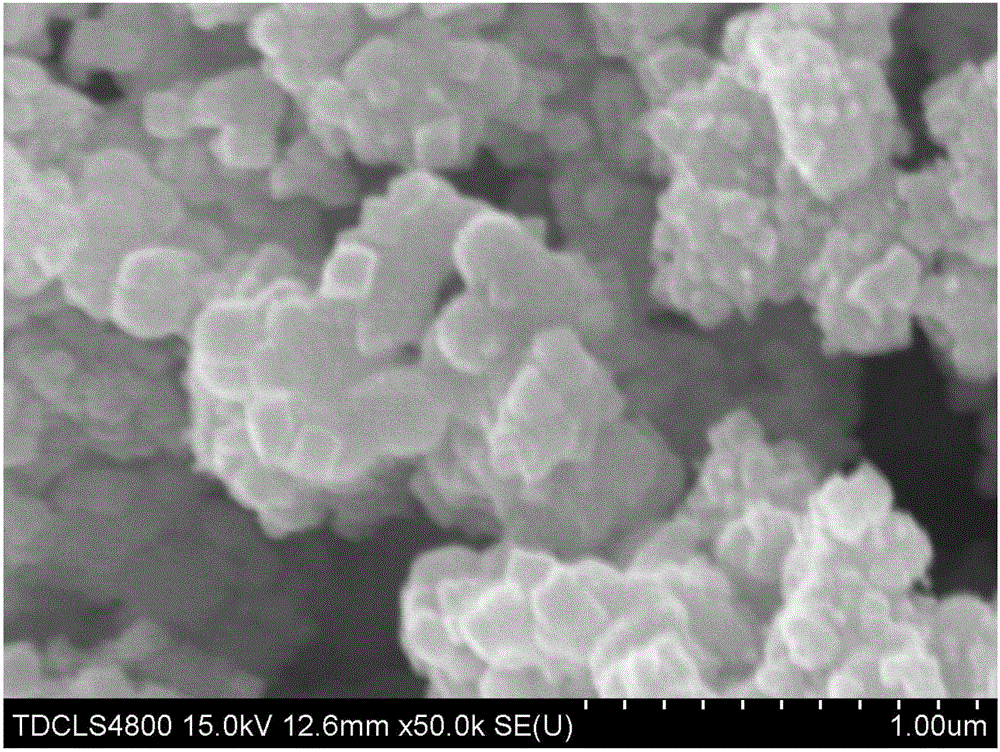

[0031] (1) Dissolve 1.29g of yttrium nitrate hexahydrate in 120mL of distilled water, use mechanical stirring and ultrasonic treatment (the speed of mechanical stirring is 1000rpm, and the power of ultrasonic treatment is 120W). After fully dissolving and dispersing, add 10gAPT and 0.25gPEG to it (The concentration of APT is 0.08g / mL, the quality of yttrium nitrate hexahydrate is 12.9% of the quality of ammonium paratungstate; the quality of surfactant is 2.5% of the quality of ammonium paratungstate), and the solution is prepared.

[0032] (2) Add 10 mL of concentrated nitric acid (the volume ratio of which to distilled water is 1 / 12) into the above solution for chemical precipitation reaction, and the reaction lasts for 30 min to form a suspension.

[0033] (3) 130 mL of absolute ethanol (1 time of the total volume of the suspension) was added to the suspension and continued to react for 4 h under the conditions of mechanical stirring and ultrasonic treatment. The suspension...

Embodiment 2

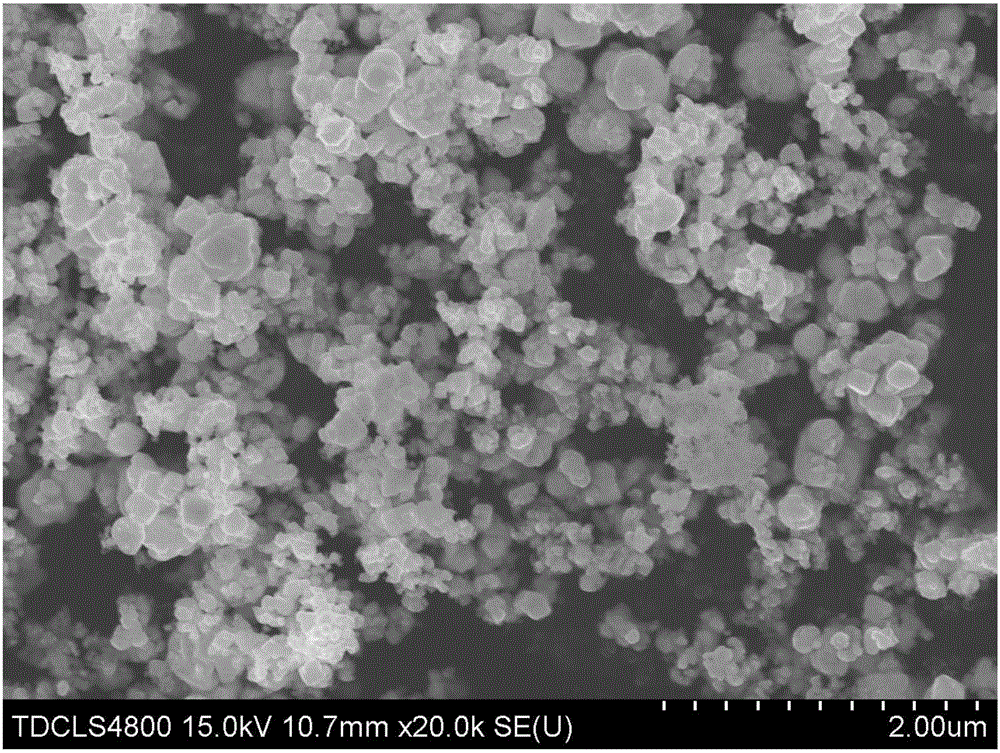

[0037] (1) Dissolve 2.57g of yttrium nitrate hexahydrate in 120mL of distilled water, mechanically stir and sonicate (the rotational speed of mechanical stirring is 2000rpm, and the power of sonication is 120W). After fully dissolving and dispersing, add 20gAPT and 2gSDS into it ( The concentration of APT is 0.25g / mL, the quality of yttrium nitrate hexahydrate is 12.9% of the ammonium paratungstate quality; The quality of surfactant is 10% of the ammonium paratungstate quality), makes solution.

[0038] (2) Add 20 mL of concentrated nitric acid (volume ratio of 1 / 6 to distilled water) into the above solution for chemical precipitation reaction, and the reaction lasts for 30 min to form a suspension.

[0039] (3) 140 mL of absolute ethanol (1 time of the total volume of the suspension) was added to the suspension and continued to react for 3 h under the conditions of mechanical stirring and ultrasonic treatment. The suspension was then vacuum filtered and the obtained precipitate...

Embodiment 3

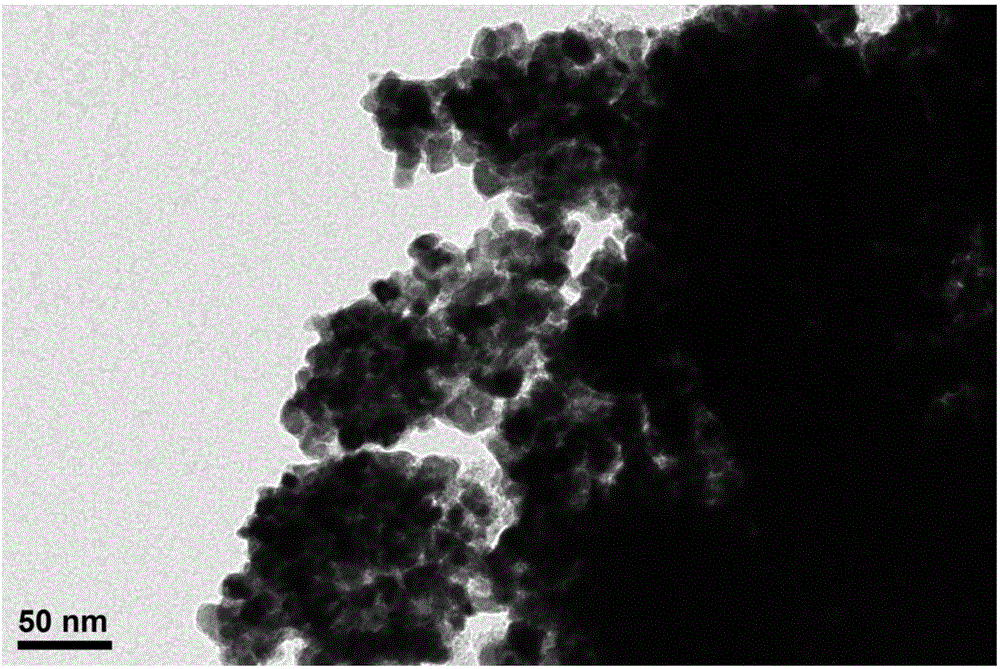

[0042] (1) Dissolve 2.57g of yttrium nitrate hexahydrate in 120mL of distilled water, and use mechanical stirring and ultrasonic treatment (the rotating speed of mechanical stirring is 2000rpm, and the power of ultrasonic treatment is 100W). After fully dissolving and dispersing, add 20gAPT and 3gPVP into it ( The concentration of APT is 0.17g / mL, the quality of yttrium nitrate hexahydrate is 12.9% of ammonium paratungstate quality; The quality of surfactant is 15% of ammonium paratungstate quality), makes solution.

[0043] (2) Add 20 mL of concentrated nitric acid (volume ratio of 1 / 6 to distilled water) into the above solution for chemical precipitation reaction, and the reaction lasts for 30 min to form a suspension.

[0044] (3) 140 mL of absolute ethanol (1 time of the total volume of the suspension) was added to the suspension and continued to react for 3 h under the conditions of mechanical stirring and ultrasonic treatment. The suspension was then vacuum filtered and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com