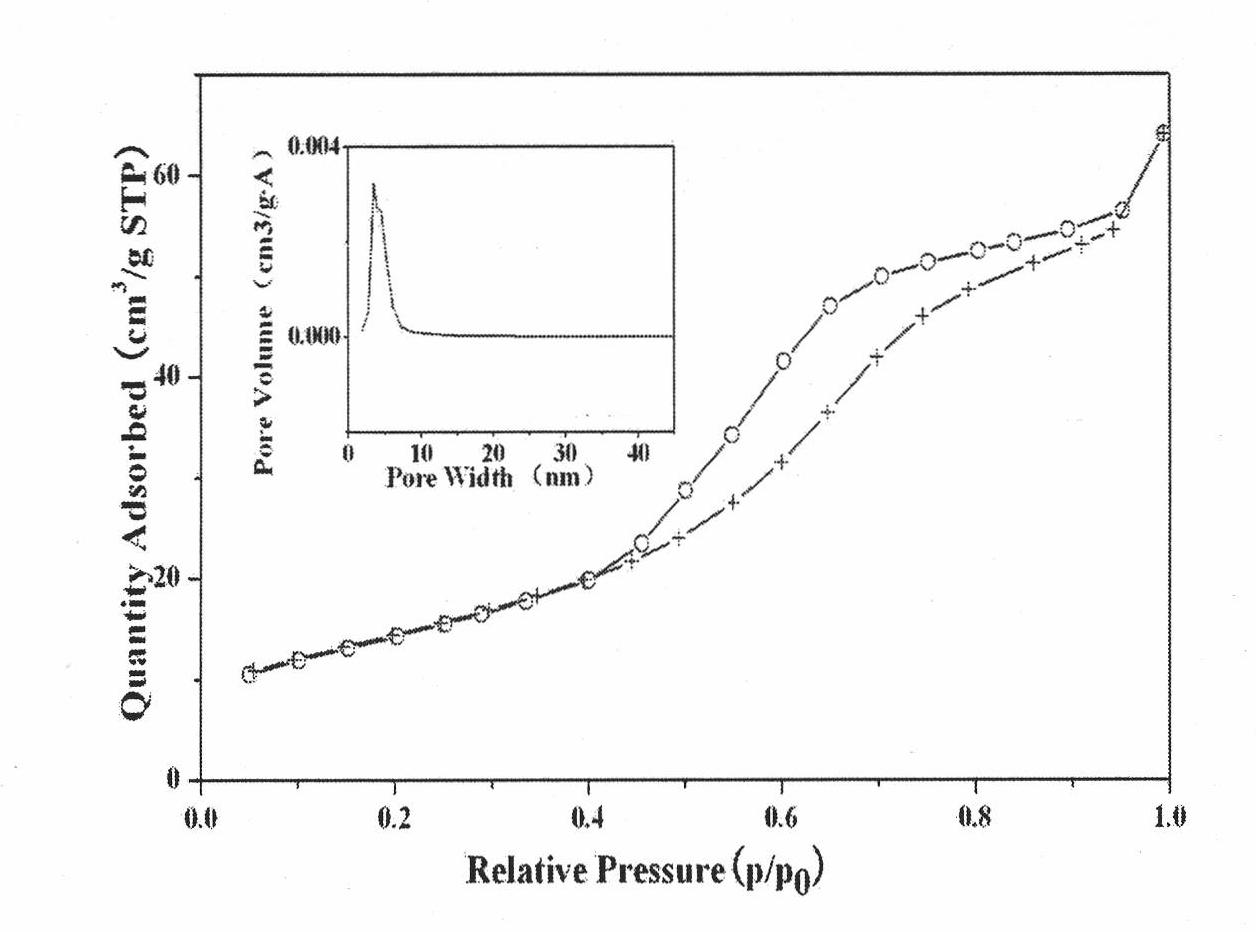

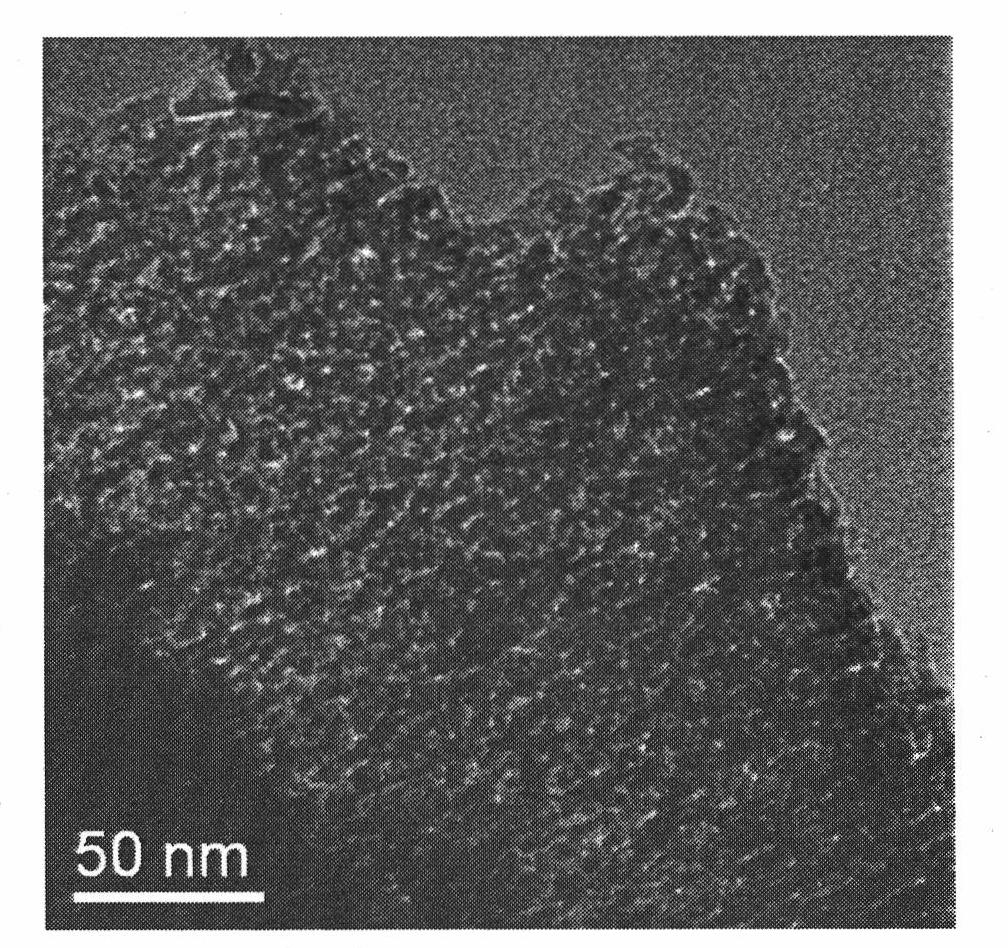

Mesoporous tungstate photocatalysis material and preparation method thereof

A technology of mesoporous tungstate and tungstate, which is applied in chemical instruments and methods, tungsten compounds, physical/chemical process catalysts, etc., to achieve the effects of improving thermal stability, protecting against collapse, and avoiding fusion growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] W excess

[0033] Dissolve 0.004mol ammonium tungstate in 100ml water, accelerate the dissolution in ultrasonic to obtain a clear liquid. Dissolve 0.004mol bismuth nitrate in 100ml acetic acid and stir until completely dissolved. The above two solutions were mixed to form a milky white cloudy liquid, and the cloudy liquid was stirred, heated and evaporated to dryness to obtain a solid. The obtained solid is calcined at 200-1000°C. The calcined product was treated with 1M Na 2 CO 3 treatment, the mesoporous Bi 2 WO 6 photocatalytic material.

Embodiment 2

[0035] Excess Bi

[0036] Dissolve 0.004mol ammonium tungstate in 100ml water, accelerate the dissolution in ultrasonic to obtain a clear liquid. Dissolve 0.012mol bismuth nitrate in 100ml acetic acid and stir until completely dissolved. The above two solutions were mixed to form a milky white cloudy liquid, and the cloudy liquid was stirred, heated and evaporated to dryness to obtain a solid. The obtained solid is calcined at 200-1000°C. Treat the calcined product with 50% acetic acid solution to obtain mesoporous Bi 2 WO 6 photocatalytic material.

Embodiment 3

[0038] use chelating agents

[0039] Dissolve 0.004mol ammonium tungstate in 100ml water, add 0.008mol citric acid, and accelerate the dissolution in ultrasonic to obtain a clear liquid. Dissolve 0.012mol bismuth nitrate and 0.024mol EDTA in 100ml water and stir until completely dissolved. The above two solutions were mixed to form a milky white cloudy liquid, and the cloudy liquid was stirred and evaporated to dryness to obtain a solid. The obtained solid is calcined at 200-1000°C. Treat the calcined product with 50% acetic acid solution to obtain mesoporous Bi 2 WO 6 photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com