A high sphericity tritium multiplication agent nanostructure lithium titanate ceramic pellets and preparation method thereof

A technology of structural lithium titanate and tritium multiplier, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of unsatisfactory sphericity of small balls, affect engineering use, and high surface energy, so as to reduce radiation exposure Crack condition, uniform structure, effect of improving sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

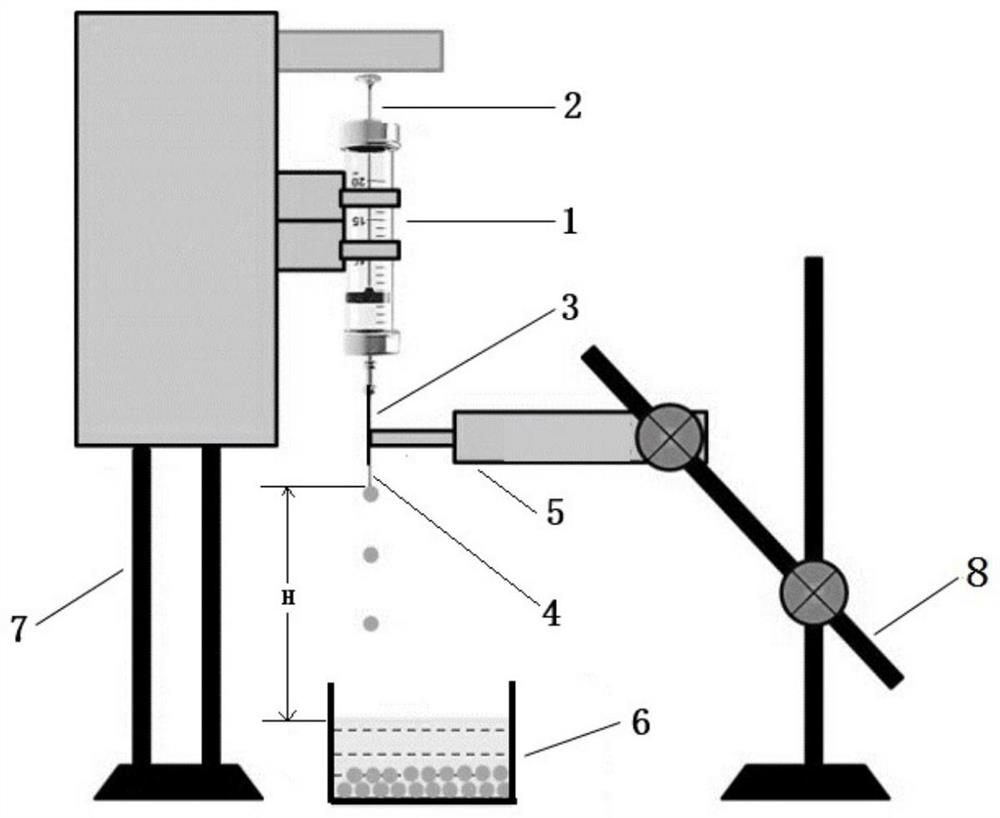

Method used

Image

Examples

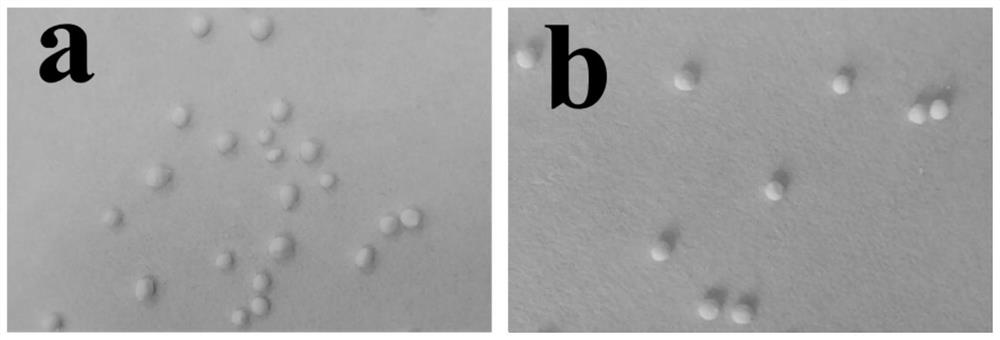

Embodiment 1

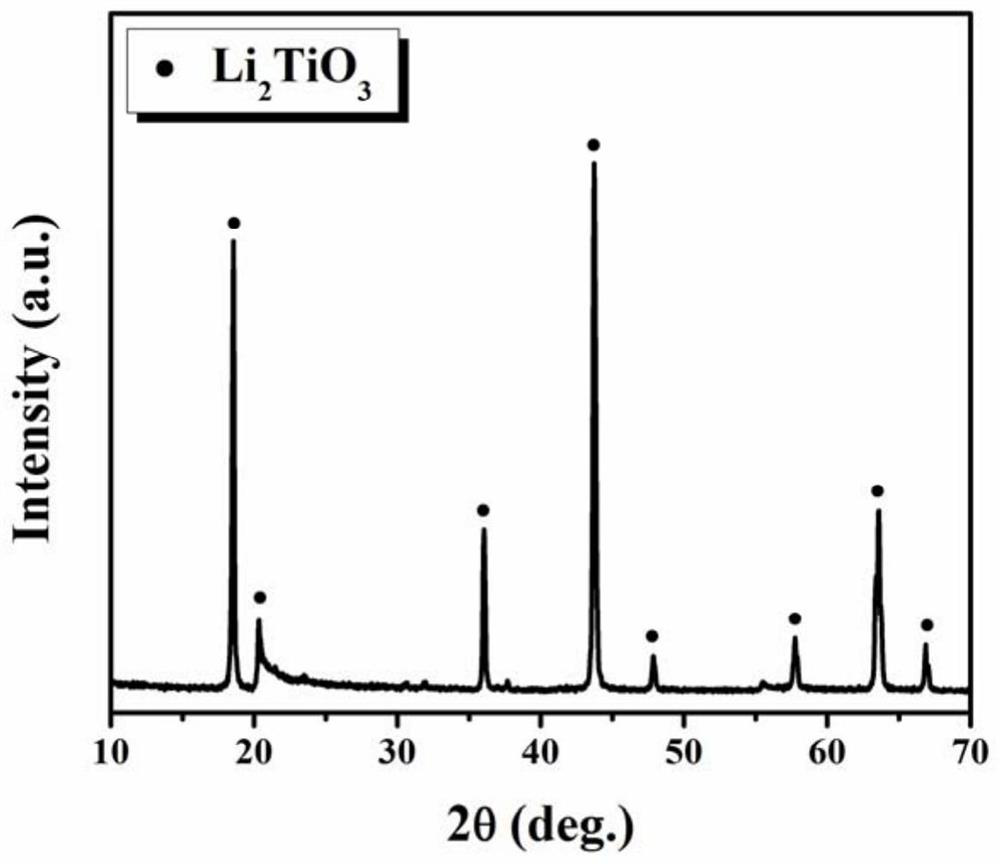

[0042] (1) Preparation of precursor powder

[0043] Add 10.172g of lithium hydroxide monohydrate into a mixed solvent composed of 40ml of ethanol and 80ml of deionized water, and heat and stir in an oil bath at 50°C for 50min until the lithium hydroxide is completely dissolved to obtain a lithium ion concentration of 2.0mol / L solution; then 9.604g particle size 5~10nm anatase nano-titanium dioxide and 2.652g CTAB are added successively to the solution that is dissolved with lithium hydroxide to obtain a mixed solution, and the gained mixed solution is transferred to a 150ml reaction kettle, and the temperature is raised to React at 200°C for 20 hours; after the reaction, separate the product and dry the product at 70°C for 24 hours, then grind the dried product and pass through a 250-mesh sieve to obtain the precursor powder.

[0044] (2) Preparation of lithium titanate ceramic pellets

[0045] ① Prepare the premix, put 1.5mL fish oil and 8.5mL deionized water in a beaker, th...

Embodiment 2

[0059] (1) Preparation of precursor powder

[0060] Add 10.172g of lithium hydroxide monohydrate into a mixed solvent composed of 40ml of ethanol and 80ml of deionized water, and heat and stir in an oil bath at 50°C for 50min until the lithium hydroxide is completely dissolved to obtain a lithium ion concentration of 2.0mol / L solution; then 9.604g particle size 5~10nm anatase nano-titanium dioxide and 2.652g CTAB are added successively to the solution that is dissolved with lithium hydroxide to obtain a mixed solution, and the gained mixed solution is transferred to a 150ml reaction kettle, and the temperature is raised to React at 200°C for 20 hours; after the reaction, separate the product and dry the product at 70°C for 24 hours, then grind the dried product and pass through a 250-mesh sieve to obtain the precursor powder.

[0061](2) Preparation of lithium titanate ceramic pellets

[0062] ① Prepare the premix, put 2.5mL fish oil and 7.5mL deionized water in a beaker, the...

Embodiment 3

[0068] (1) Preparation of precursor powder

[0069] Add 10.172g of lithium hydroxide monohydrate into a mixed solvent composed of 40ml of ethanol and 80ml of deionized water, and heat and stir in an oil bath at 50°C for 50min until the lithium hydroxide is completely dissolved to obtain a lithium ion concentration of 2.0mol / L solution; then 9.604g particle size 5~10nm anatase nano-titanium dioxide and 2.652g CTAB are added successively to the solution that is dissolved with lithium hydroxide to obtain a mixed solution, and the gained mixed solution is transferred to a 150ml reaction kettle, and the temperature is raised to React at 200°C for 20 hours; after the reaction, separate the product and dry the product at 70°C for 24 hours, then grind the dried product and pass through a 250-mesh sieve to obtain the precursor powder.

[0070] (2) Preparation of lithium titanate ceramic pellets

[0071] ①To prepare the premix, put 1.0mL polyacrylic acid and 9.0mL deionized water in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com