Sandwich-like hollow structure metal oxide noble metal nanoparticle metal oxide catalyst, preparation method and use thereof

A nanoparticle, hollow structure technology, applied in the field of hollow MOMMO catalysts, can solve the problems of difficult to control etching rate, local shell etching, grain shell cracking and other problems, achieve excellent catalytic performance, overcome calcination and alkali etching , the effect of excellent activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

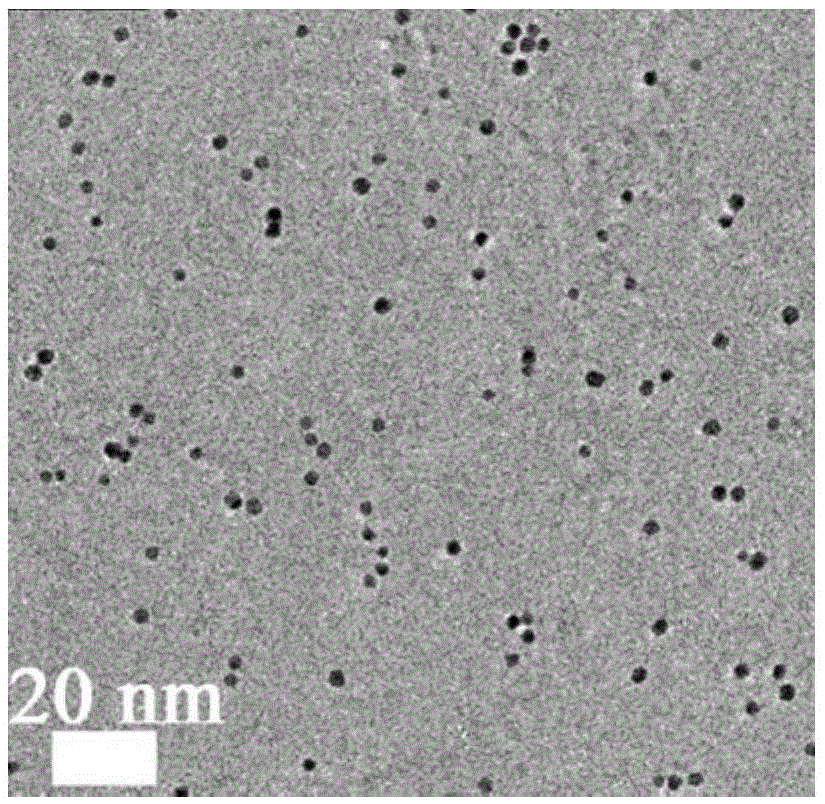

[0098] Example 1: Synthesis of gold nanoparticles

[0099] 0.85 mL of 10 mM HAuCl 4 Mix well with 0.32mL sodium citrate with a concentration of 25mM in a round bottom flask, then add ultrapure water to a solution volume of 40mL. Then, 1.05 mL of sodium borohydride with a concentration of 0.1 M was added to the above solution and magnetically stirred at 15° C. for 3 hours to obtain gold nanoparticles with a particle size of 1.3 nm.

Embodiment 2

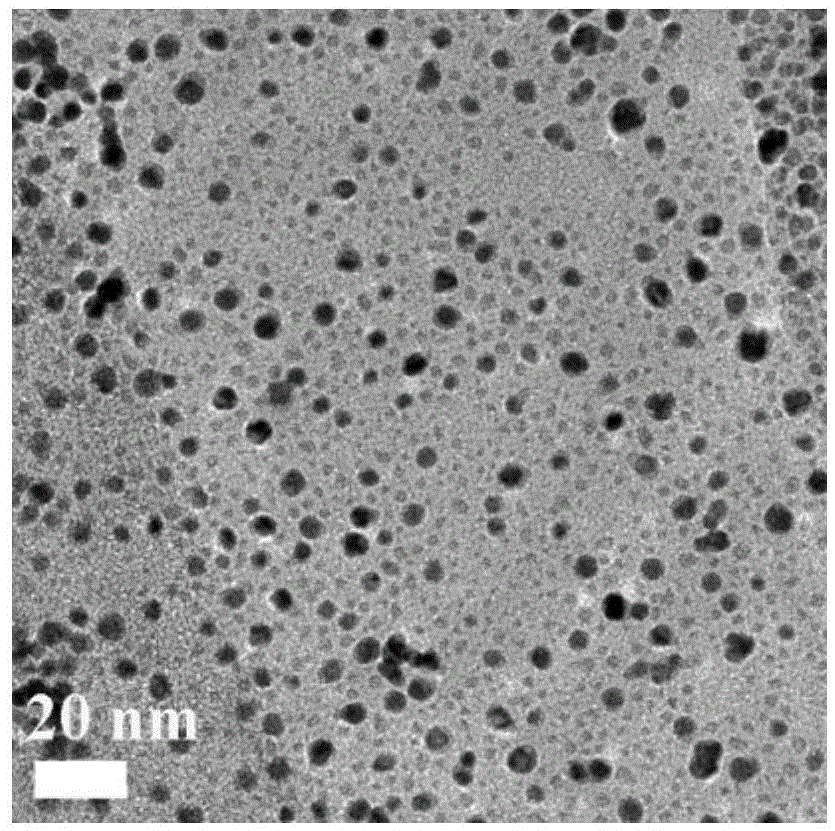

[0100] Example 2: Synthesis of gold nanoparticles

[0101] 0.85 mL of 10 mM HAuCl 4 Mix well with 0.32mL sodium citrate with a concentration of 25mM in a round bottom flask, then add ultrapure water to a solution volume of 40mL. Then, 1.05 mL of sodium borohydride with a concentration of 0.1 M was added to the above solution and magnetically stirred at 30° C. for 8 hours to obtain gold nanoparticles with a particle size of 1.8 nm.

Embodiment 3

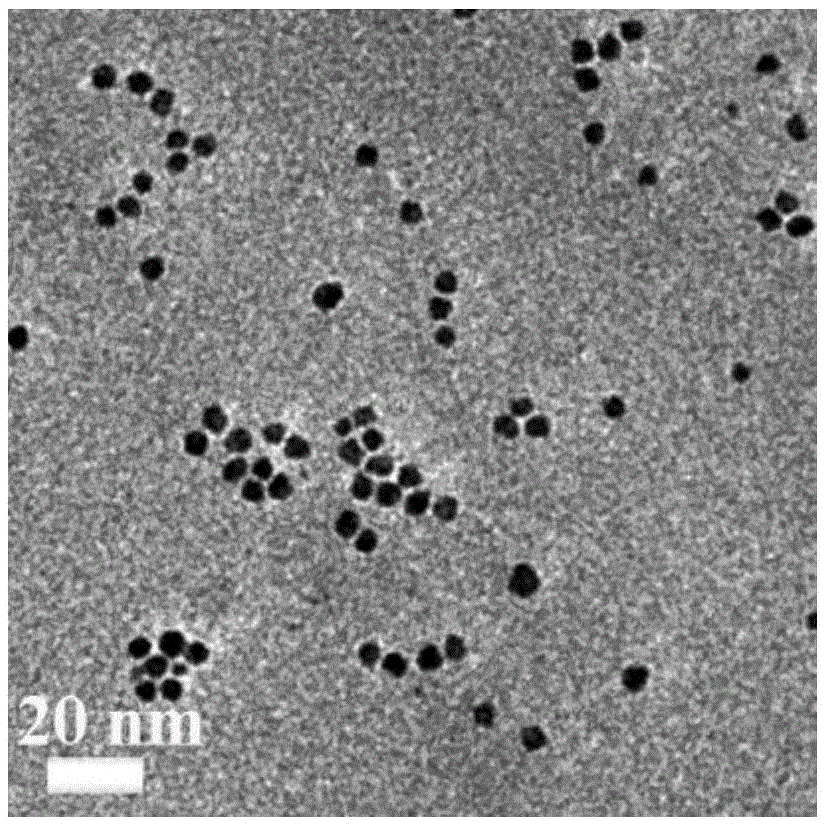

[0102] Example 3: Synthesis of gold nanoparticles

[0103] 0.85 mL of 10 mM HAuCl 4 Mix well with 0.32mL sodium citrate with a concentration of 25mM in a round bottom flask, then add ultrapure water to a solution volume of 40mL. Then 1.05 mL of sodium borohydride with a concentration of 0.1 M was added to the above solution and magnetically stirred at 45° C. for 12 hours to obtain gold nanoparticles with a particle size of 2.1 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com