Carbon-coated lithium iron phosphate cathode material and preparation method thereof

A carbon-coated lithium iron phosphate and cathode material technology, which is applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as high price, difficulty in achieving good dispersion between nanoparticles, and lithium iron phosphate losing its cost-effectiveness advantage. Facilitate production management, improve electrochemical performance, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] One aspect of the present invention provides a method for preparing a carbon-coated lithium iron phosphate cathode material, comprising the following steps:

[0025] mixing an iron-containing compound, a lithium-containing compound, a phosphorus-containing compound, and a polymer dispersant with a solvent to form a first slurry;

[0026] mixing the first slurry with oligosaccharides to form a second slurry;

[0027] drying the second slurry to make a precursor;

[0028] After the precursor is calcined, a graphitized carbon-coated lithium iron phosphate cathode material is obtained.

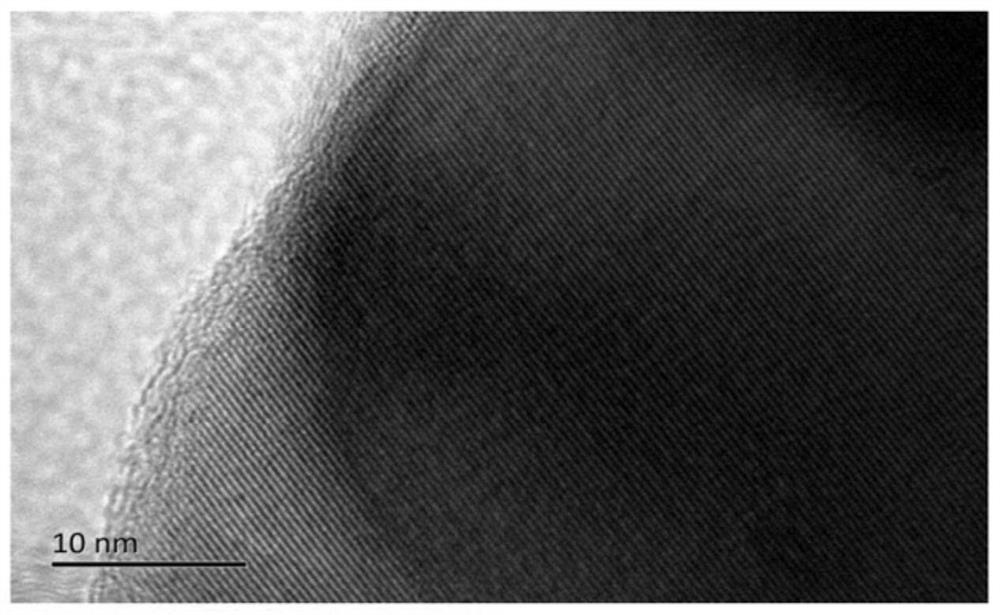

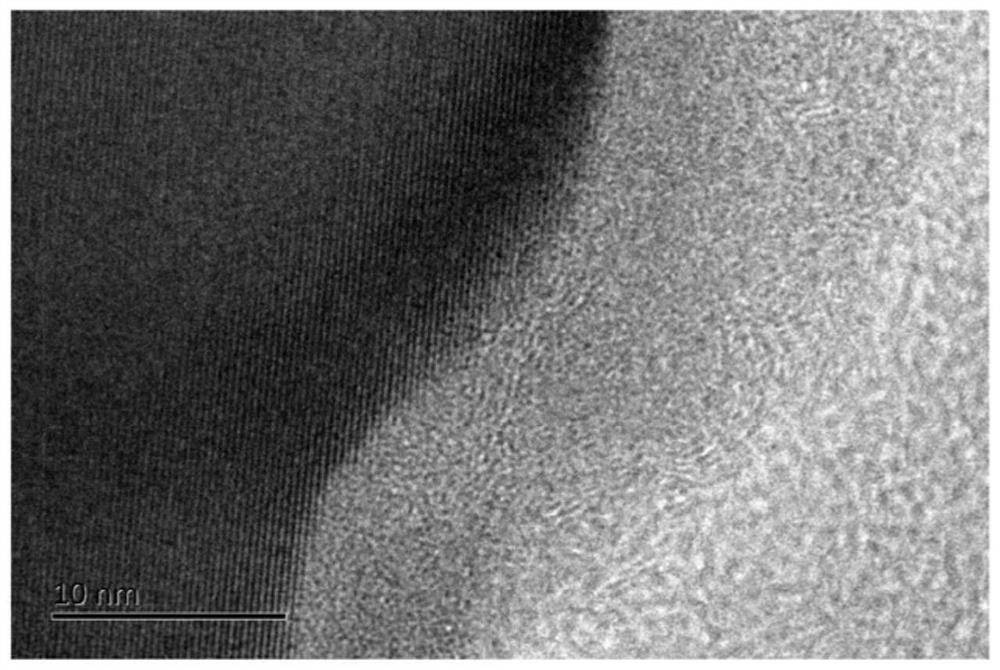

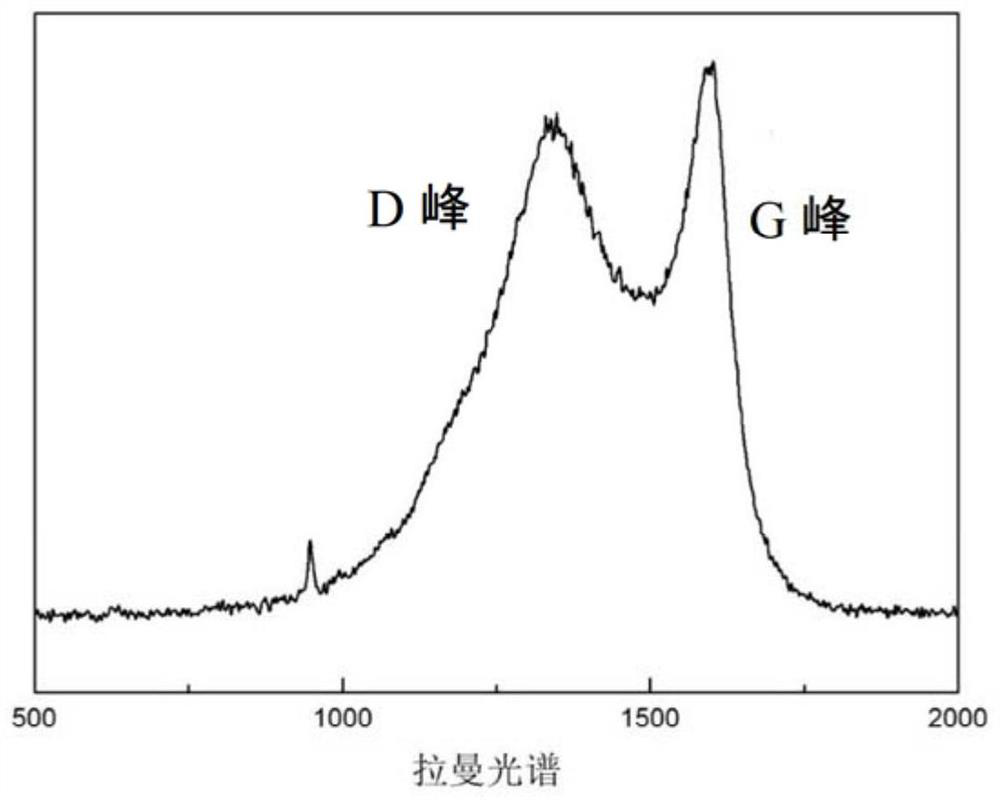

[0029] Based on the concept of organic carbon cracking to generate carbon layers in situ on the surface of lithium iron phosphate nanoparticles, the present invention proposes a method for combined design of organic carbon sources: through the combined use of oligosaccharides and polymer dispersants, only by adding a small amount of organic The carbon source can form a uniform, ultra-thin...

Embodiment 1

[0047] Accurately weigh 1000g of commercially available ferric orthophosphate, 13.5g of lithium dihydrogen phosphate, 246g of lithium carbonate, 11g of PEG8000 and 5.5g of PEG4000 (the molar ratio of PEG8000 and PEG4000 is 1:1), add 2000g of deionized water, and use a ball mill to pre-grind After mixing for 2 hours, add 100 g of glucose, continue grinding for 2 hours, and send the slurry to a sand mill for grinding. After the particle size reaches 0.30±0.05 μm, the slurry is spray-dried, and the dried precursor is placed in a nitrogen atmosphere furnace. The temperature was raised to 650°C at a heating rate of 5°C / min, and then cooled to room temperature after calcination at a constant temperature for 10 hours. After the material was pulverized, a lithium iron phosphate cathode material coated with a combined carbon source was obtained.

[0048] The median particle size of the product obtained in this example is 1.5 μm, and the tap density is 1.08 g / cm 3 , the carbon content i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com