Preparation method of cesium tungstate nanopowder

A nano-powder, cesium tungstate technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as difficult and low-cost applications, and achieve the effects of high production efficiency, light degree of agglomeration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

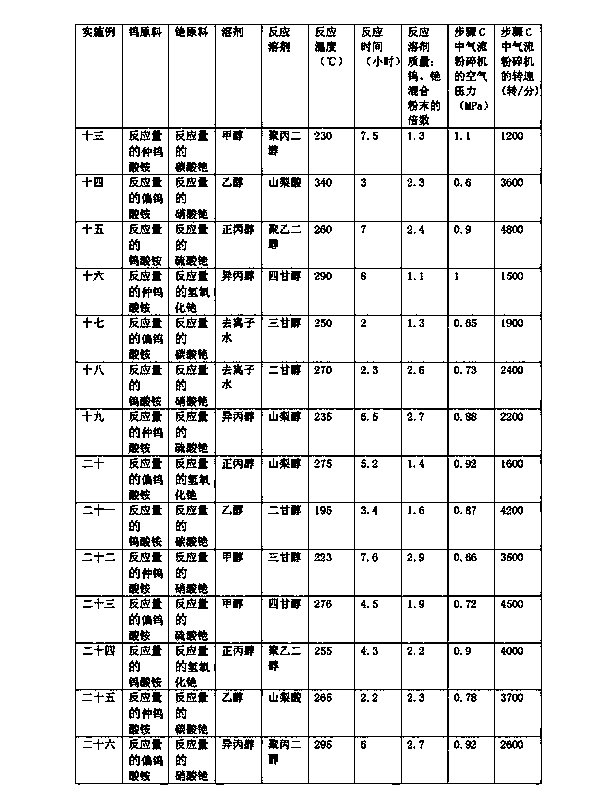

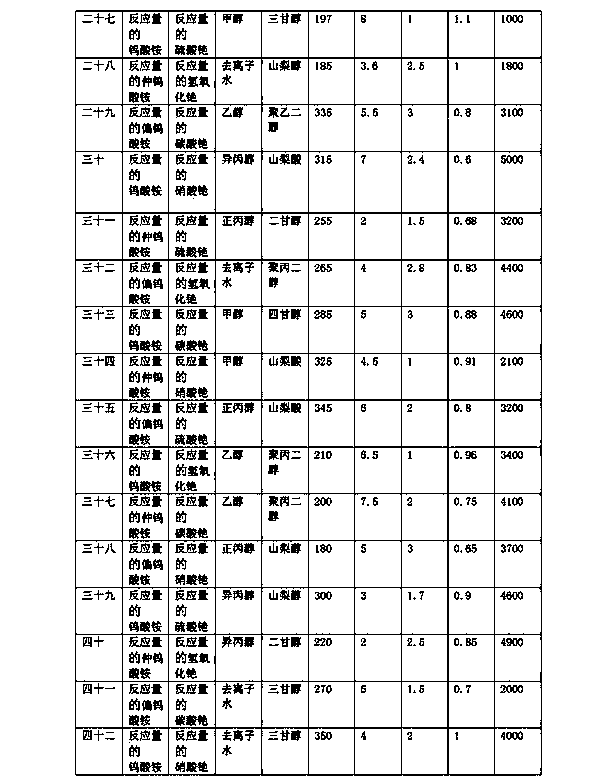

Examples

Embodiment 1

[0017] A preparation method of cesium tungstate nanopowder is characterized in that comprising the following steps:

[0018] A. Dissolve the reaction amount of ammonium paratungstate as tungsten raw material and cesium carbonate as cesium raw material in methanol solvent, dry the above solution to obtain powder, and then further pulverize the obtained powder to obtain tungsten and cesium mixed powder. The pulverization here can adopt conventional pulverization methods, such as mechanical pulverization (such as ball mill pulverization), jet pulverization, etc.; the drying here can also adopt conventional drying methods, such as oven drying, spray drying, freeze drying or boiling drying, etc.

[0019] B. Place the mixed powder of tungsten and cesium in a closed reaction kettle with stirring, and add sorbitol as a reaction solvent to it, and stir and react for 6 hours at 300 ° C. The quality of the reaction solvent is the mixed powder of tungsten and cesium 2 times the mass;

[...

Embodiment 2

[0022] A preparation method of cesium tungstate nanopowder is characterized in that comprising the following steps:

[0023] A. Dissolve the reaction amount of ammonium paratungstate as tungsten raw material and cesium nitrate as cesium raw material in solvent ethanol, dry the above solution to obtain powder, and then further pulverize the obtained powder to obtain tungsten and cesium mixed powder. The pulverization here can adopt conventional pulverization methods, such as mechanical pulverization (such as ball mill pulverization), jet pulverization, etc.; the drying here can also adopt conventional drying methods, such as oven drying, spray drying, freeze drying or boiling drying, etc.

[0024] B. Put the mixed powder of tungsten and cesium in a closed reaction kettle with stirring, and add diethylene glycol as a reaction solvent to it, and stir and react for 4 hours at 180 ° C. The quality of the reaction solvent is tungsten and cesium. 1.2 times the powder mass;

[0025] ...

Embodiment 3

[0027] A preparation method of cesium tungstate nanopowder is characterized in that comprising the following steps:

[0028] A. Dissolve the reaction amount of ammonium paratungstate as tungsten raw material and cesium sulfate as cesium raw material in n-propanol solvent, dry the above solution to obtain powder, and then further pulverize the obtained powder to obtain tungsten and cesium mixed powder . The pulverization here can adopt conventional pulverization methods, such as mechanical pulverization (such as ball mill pulverization), jet pulverization, etc.; the drying here can also adopt conventional drying methods, such as oven drying, spray drying, freeze drying or boiling drying, etc.

[0029] B. Put the mixed powder of tungsten and cesium in a closed reaction kettle with stirring, and add triethylene glycol as a reaction solvent to it, and stir and react for 4.5 hours at 330°C. The quality of the reaction solvent is a mixture of tungsten and cesium. 1 times the mass o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com