Superfine transition metal boride powder as well as preparation method and application thereof

A transition metal and boride technology, which is applied in the field of ultrafine transition metal boride powder and its preparation, can solve the problems of unfavorable powder sintering and post-processing, difficult to remove residues, coarse powder particle size, etc. Good high temperature resistance, low agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Choose HfO 2 、 Ta 2 o 5 and B powder as powder raw material, HfO 2 、 Ta 2 o 5 The particle size distributions of powder B and B are 0.2μm, 0.1μm and 0.5μm respectively, and 100mmol HfO 2 Doped with 2.5mol% Ta 2 o 5 HfO 2 -Ta 2 o 5 Mixed powder and 393mmol simple substance B, using acetone as solvent, Si 3 N 4 The ball is the ball milling medium, mixed on a roller ball mill for 24h, and dried by rotary evaporation to obtain HfO 2 -Ta 2 o 5 -B mixed powder; wherein, the solid-dissolved TaB 2 The content x is 5mol%;

[0031] 2. Add HfO 2 -Ta 2 o 5 -B The mixed powder is placed in a graphite crucible, heated to 1000°C in a graphite furnace at an air pressure lower than 200Pa and kept for 2 hours to obtain Hf 0.95 Ta 0.05 B 2 -B 2 o 3 Powder;

[0032] 3. Will get Hf 0.95 Ta 0.05 B 2 -B 2 o 3 Under the condition that the air pressure is lower than 200Pa, the powder is continuously heated to 1500°C and kept for 1 hour to obtain ultrafine Hf 0.9...

Embodiment 2

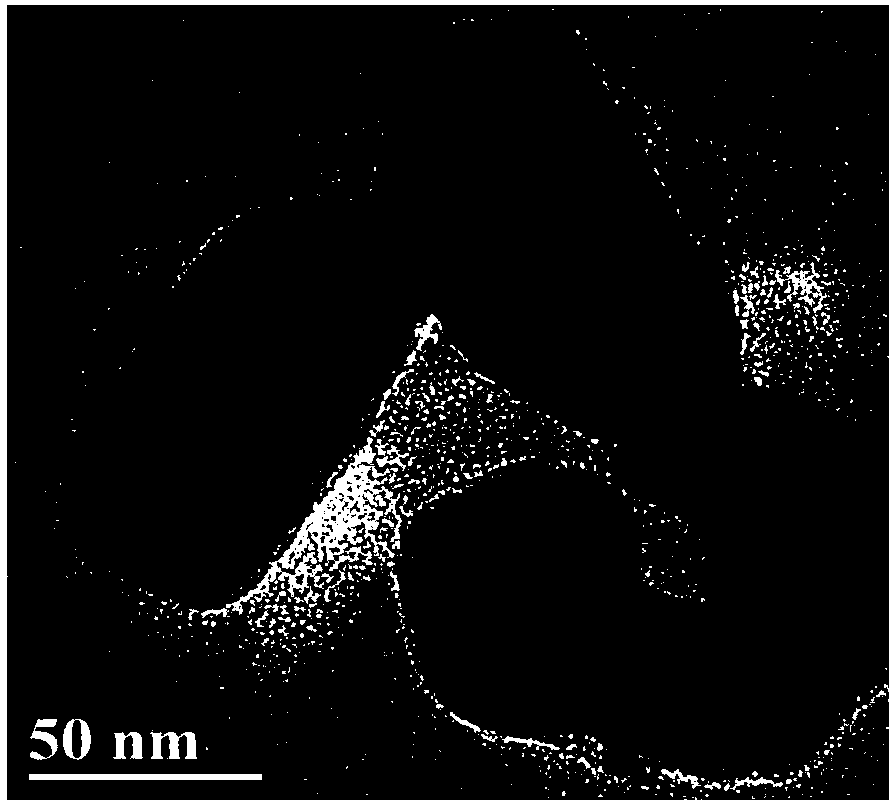

[0035] The difference between this example and Example 1 is that: the second step of high temperature insulation is 1800° C. for 2 hours. image 3 For the Hf prepared in this example 0.95 Ta 0.05 B 2 The SEM photograph of the powder, from image 3 It can be seen that the powder will not grow significantly when the temperature is raised to 1800 °C in the second step, indicating that the solid solution TaB 2 The final transition metal hafnium boride powder can inhibit the surface diffusion of hafnium boride, so that the rapid growth of hafnium boride powder at high temperature will not occur, and its high temperature stability will be enhanced. Know through detecting and analyzing: the Hf that present embodiment makes 0.95 Ta 0.05 B 2 The average particle diameter of the powder is 60nm, and the oxygen content is 0.02wt%.

Embodiment 3

[0037] The difference between this example and Example 1 is that: the second step of high temperature insulation is 2200° C. for 1 hour. Know through detecting and analyzing: the Hf that present embodiment makes 0.95 Ta 0.05 B 2 The average particle diameter of the powder is 80nm, and the oxygen content is 0.01wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com