Low temperature hermetic sealing via laser

A technology of laser and laser radiation, applied to electrical components, parallel glass structures, windows/doors, etc., can solve problems such as restrictions on the wide use of frits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments are described in detail herein with reference to the drawings, wherein like reference numerals denote like elements. It should be understood that the embodiments described herein are for illustration only, not limitation, and various modifications can be made by those skilled in the art without departing from the spirit and scope of the appended claims.

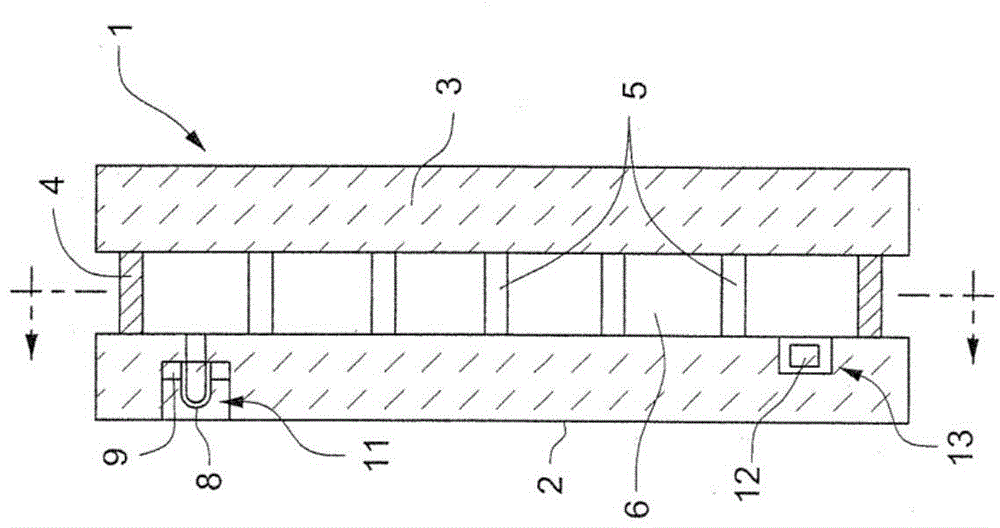

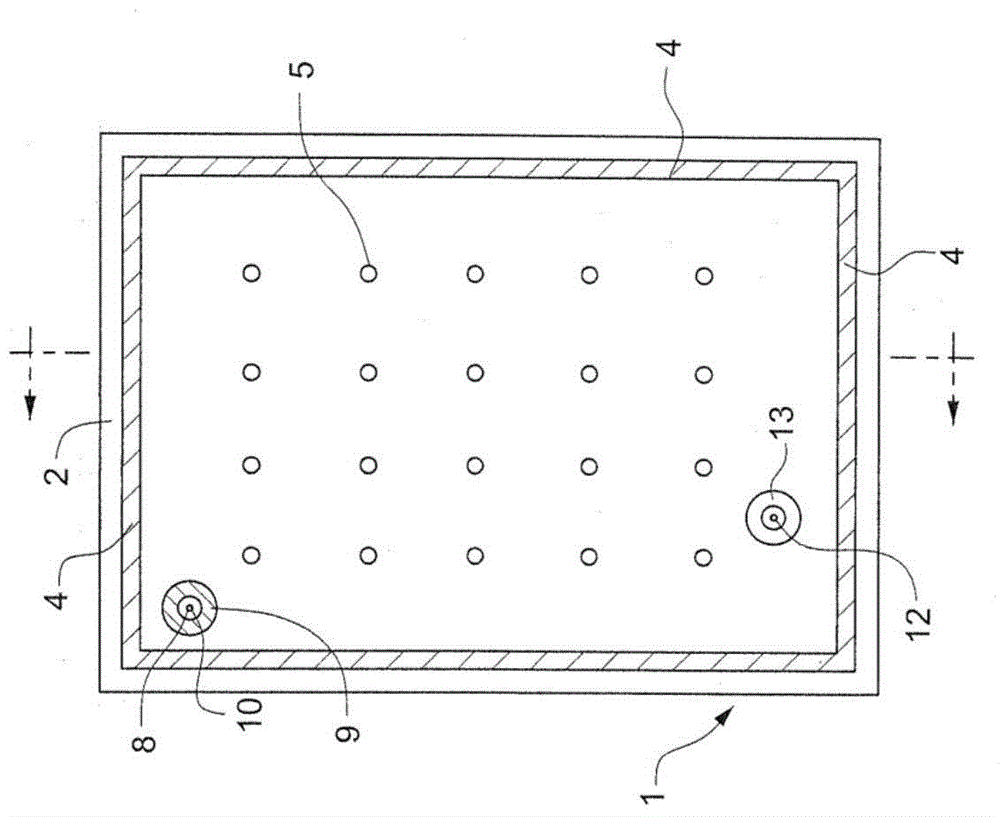

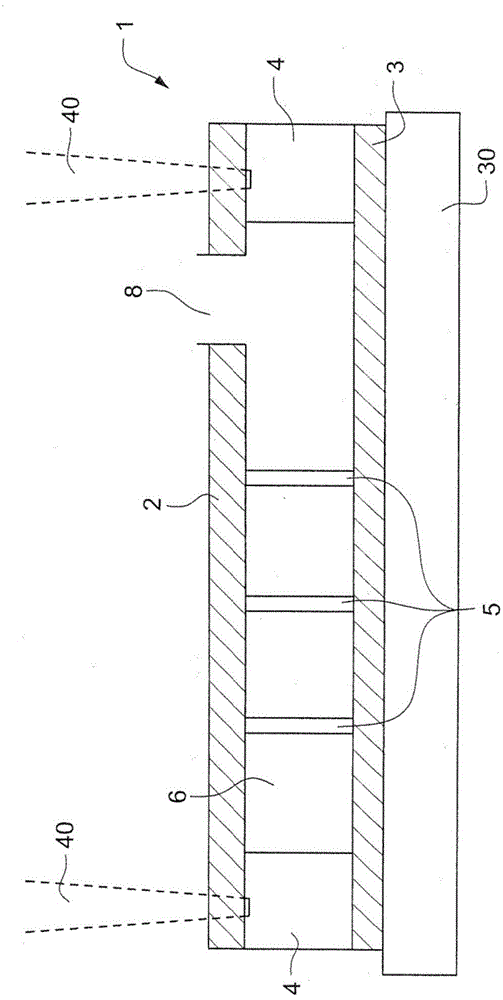

[0031] refer to image 3 , illustrating a partial cross-sectional view of a VIG unit and a sealing material irradiated by laser light according to an exemplary embodiment. The VIG unit 1 may comprise two spaced apart substantially parallel glass substrates 2, 3 enclosing an evacuated low pressure space / chamber 6 therebetween. The glass sheets or substrates 2, 3 are interconnected via peripheral edge seals 4, which may be made by using molten solder glass or the like, for example, with reference to the exemplary embodiment, by using a laser 40 as described below. A set of support posts / spacers 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com