Seal joint of deep low-temperature nonmetal pipeline

A technology for non-metallic pipes and sealing joints, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

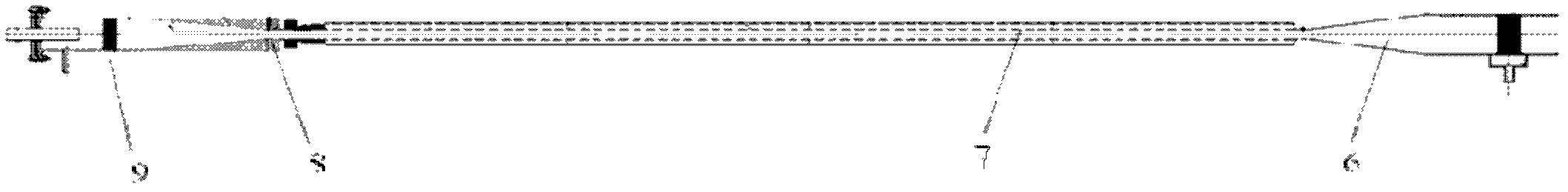

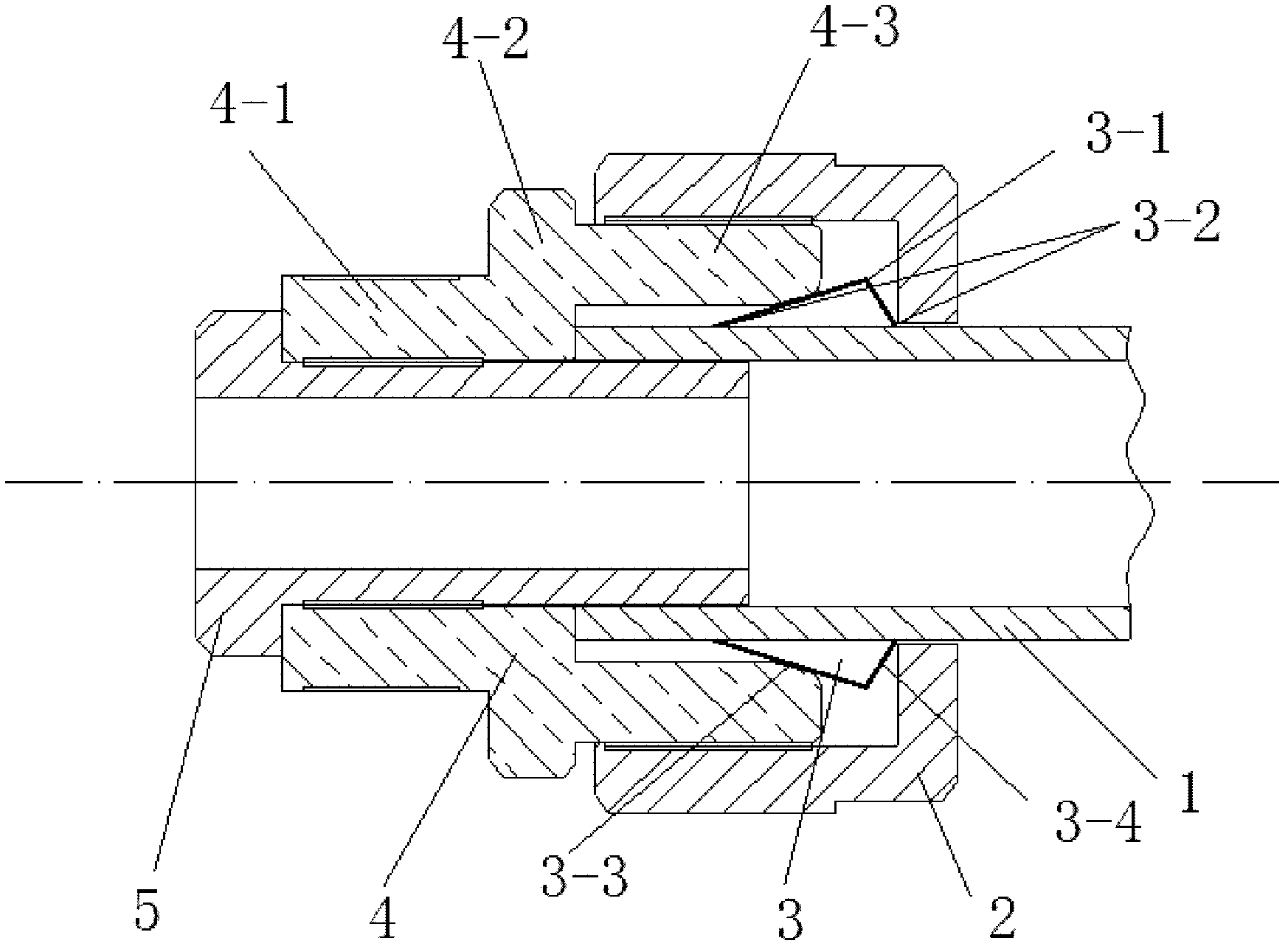

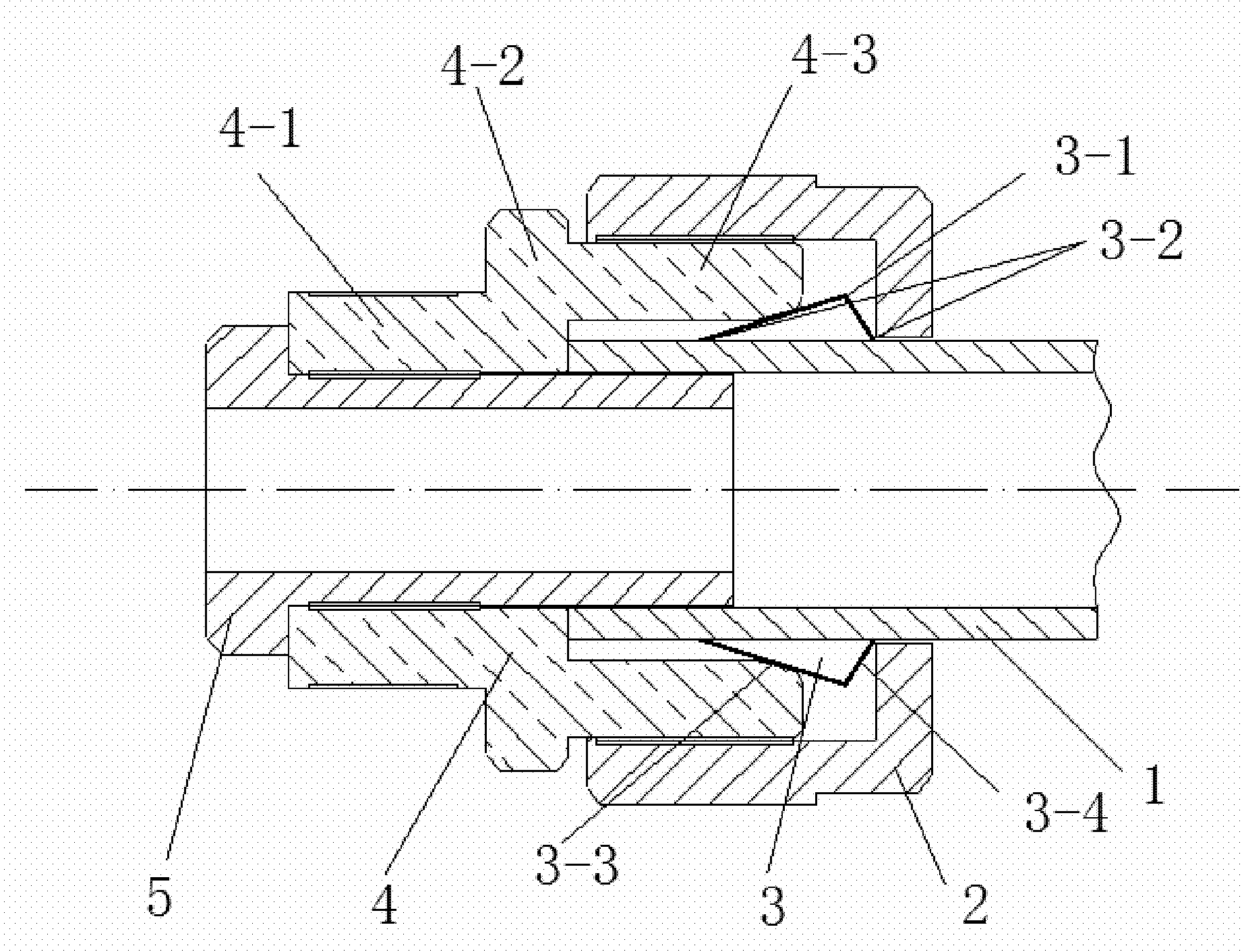

[0018] A sealed joint of a deep-low temperature non-metallic pipeline, characterized in that it includes a connecting pipeline 1, a nut 2, a metal sealing ring 3, a connecting stud 4 and an inner stud 5; the connecting pipeline 1 adopts an internal A sealing structure and an outer sealing structure, the outer sealing structure includes a connecting pipeline 1, a metal sealing ring 3, a connecting stud 4 and a nut 2; the inner sealing structure includes a connecting pipeline 1, an inner stud 5 and a connecting Stud 4.

[0019] The sealing joint of the deep-low temperature non-metallic pipeline is characterized in that: in the external sealing structure of the pipeline, the connecting pipeline 1, the metal sealing ring 3, the connecting stud 4 and the nut 5 are coaxially arranged, wherein the connecting stud The column 4 is a hollow variable-diameter structure, which is composed of three parts: the front stud 4-1, the middle hexagonal nut 4-2 and the rear stud 4-3. Part of it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com