Liquid helium temperature cryogenic target for impact compression test

A low-temperature target and liquid helium technology, which is applied in the field of refrigeration and low temperature, can solve the problems of increasing consumption of liquid helium, inability to liquefy samples, and storing too much liquid helium, so as to reduce the consumption of liquid helium, shorten the liquefaction time, and reduce the volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

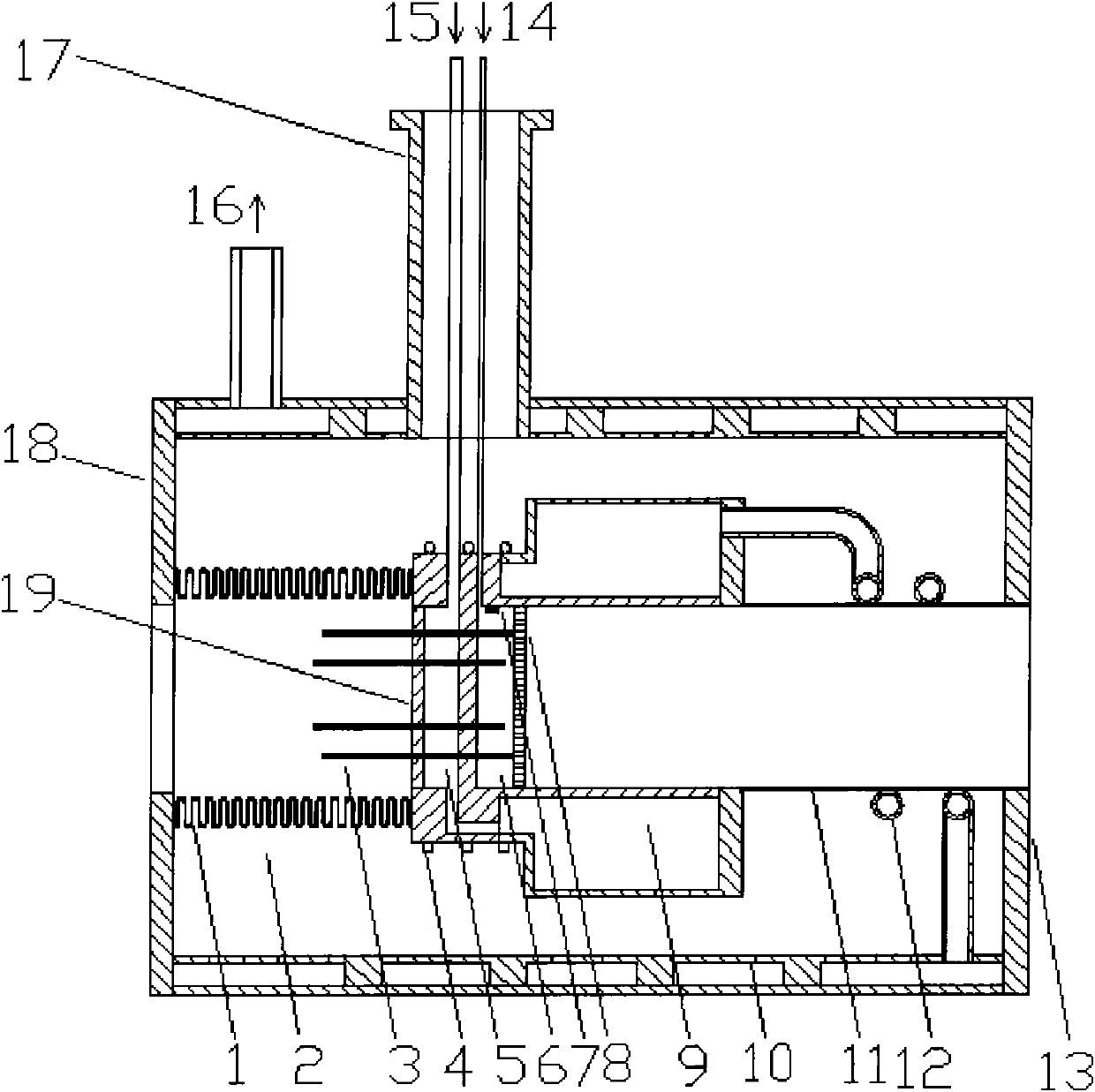

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

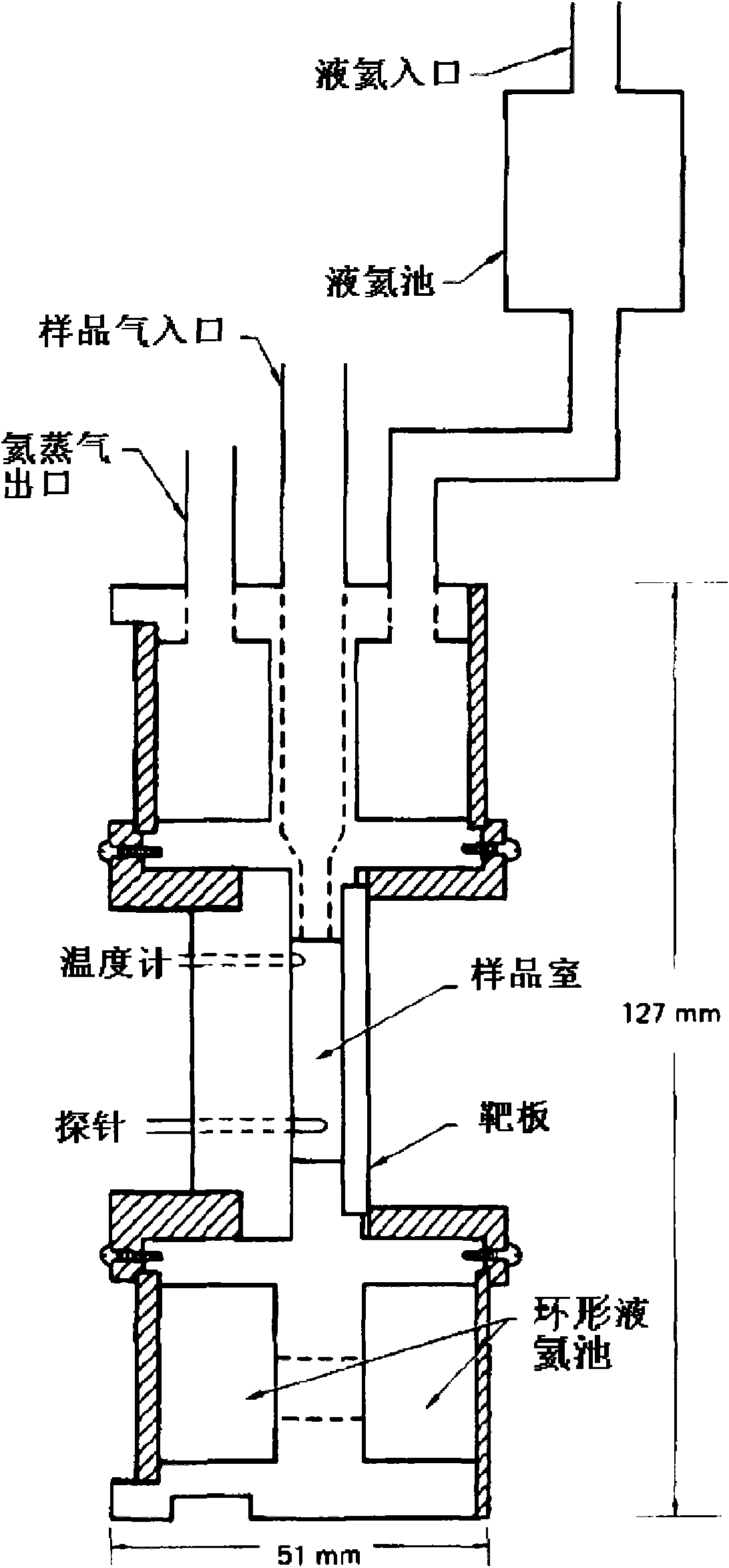

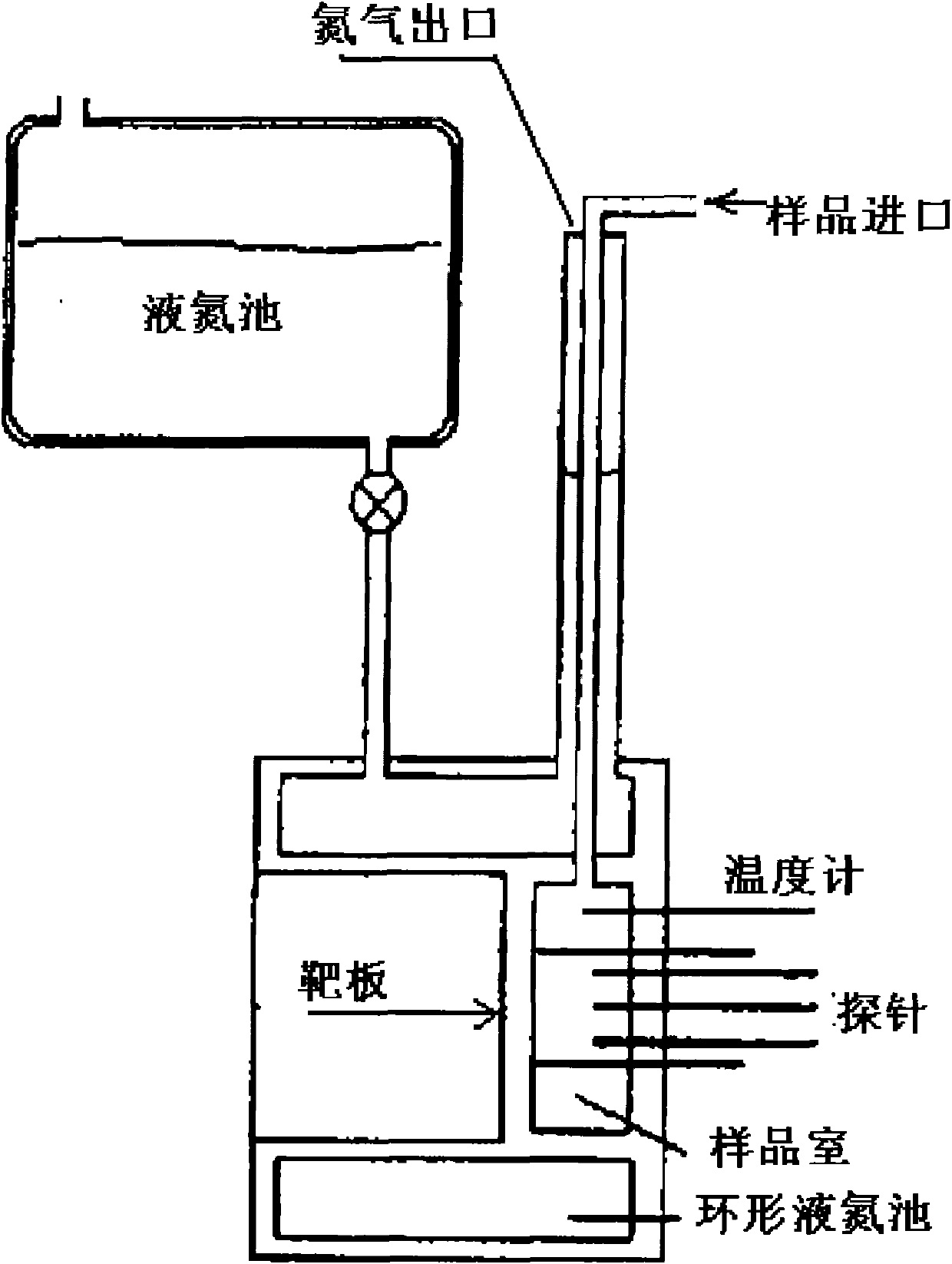

[0053] image 3 It is a structural schematic diagram of the liquid helium temperature cryogenic target of the present invention; Figure 4 It is a schematic diagram of the distribution of the probes; as can be seen from the figure, the liquid helium temperature cryogenic target used in the shock compression experiment provided by the present invention includes:

[0054] A gas-cooled screen inner cylinder, the wall of the air-cooled screen inner cylinder is engraved with a spiral groove;

[0055] An air-cooled panel outer cylinder that is tightly fitted on the outer wall of the air-cooled panel inner cylinder; a spiral groove is formed between the inner wall of the air-cooled panel outer cylinder and the spiral groove on the inner wall of the air-cooled panel. The air-cooled panel cavity 10; the air-cooled panel inner cylinder and the air-coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com