Spent bleaching clay non-pollution treatment process and equipment

A treatment process and treatment equipment technology, applied in the field of pollution-free treatment, can solve the problems of high equipment investment cost, complex process, secondary pollution, etc., and achieve the effect of high recovery rate, simple process and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

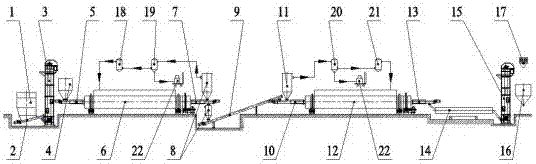

[0020] The present invention is described in detail in conjunction with accompanying drawing and specific embodiment:

[0021] The pollution-free treatment process of waste clay described in this embodiment includes low-temperature thermal distillation and high-temperature calcination, and the specific implementation steps are as follows:

[0022] 1) The low-temperature thermal distillation method is to heat to 250°C-400°C by adding an inert atmosphere or a vacuum atmosphere in a low-temperature rotary heating furnace, and after 1-2 hours of heat preservation, water vapor and some organic matter are generated, which are condensed , Oil-water separation to obtain oil, waste water, waste gas.

[0023] Heating to 400°C in a low-temperature rotary heating furnace in an inert atmosphere or a vacuum atmosphere, and holding the temperature for 2 hours, the oil removal rate can reach 39%, of which the non-condensable gas (CH 4 , NH 3 , N 2 h 4 、C 3 h 8 and C 4 h 10 etc.) accou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com