Coal mine underground low-temperature closed coal core drilling device and method

A low-temperature, coal-core technology, which is used in the extraction of undisturbed core devices, earth-moving drilling, etc., can solve the problems of gas dissipation, long exposure time, and aggravate the gas emission rate, and achieve the effect of reducing the gas emission effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

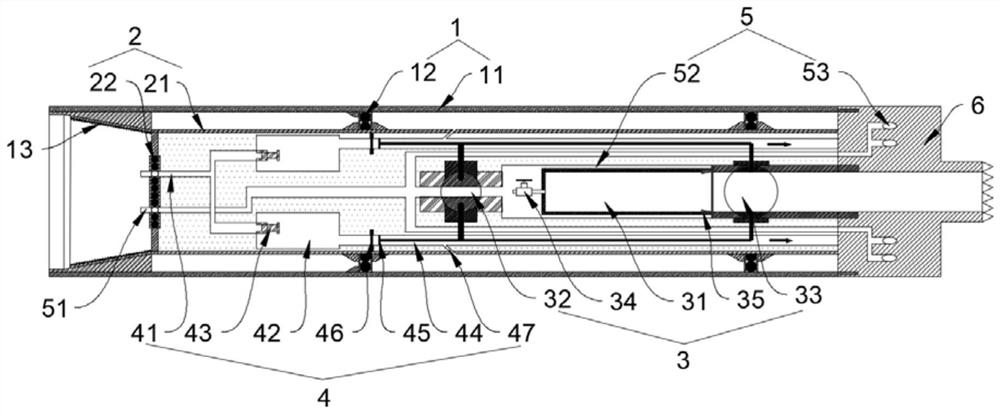

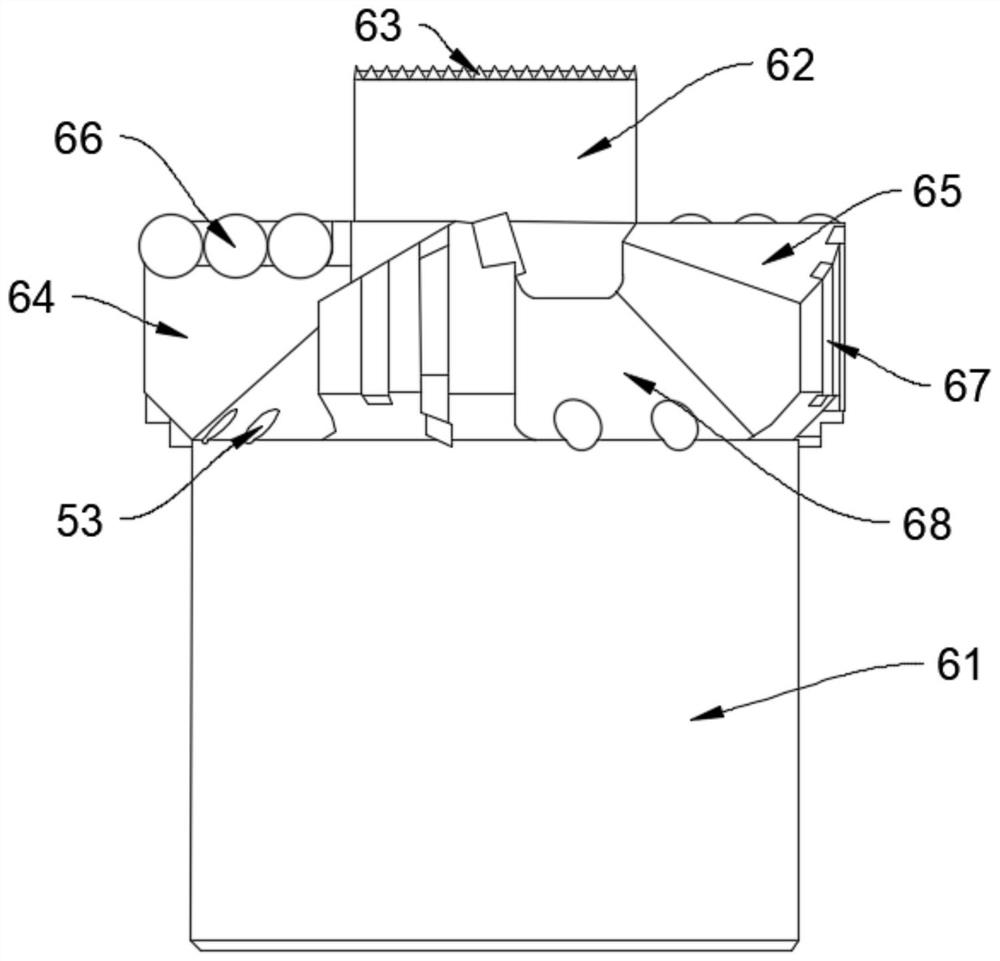

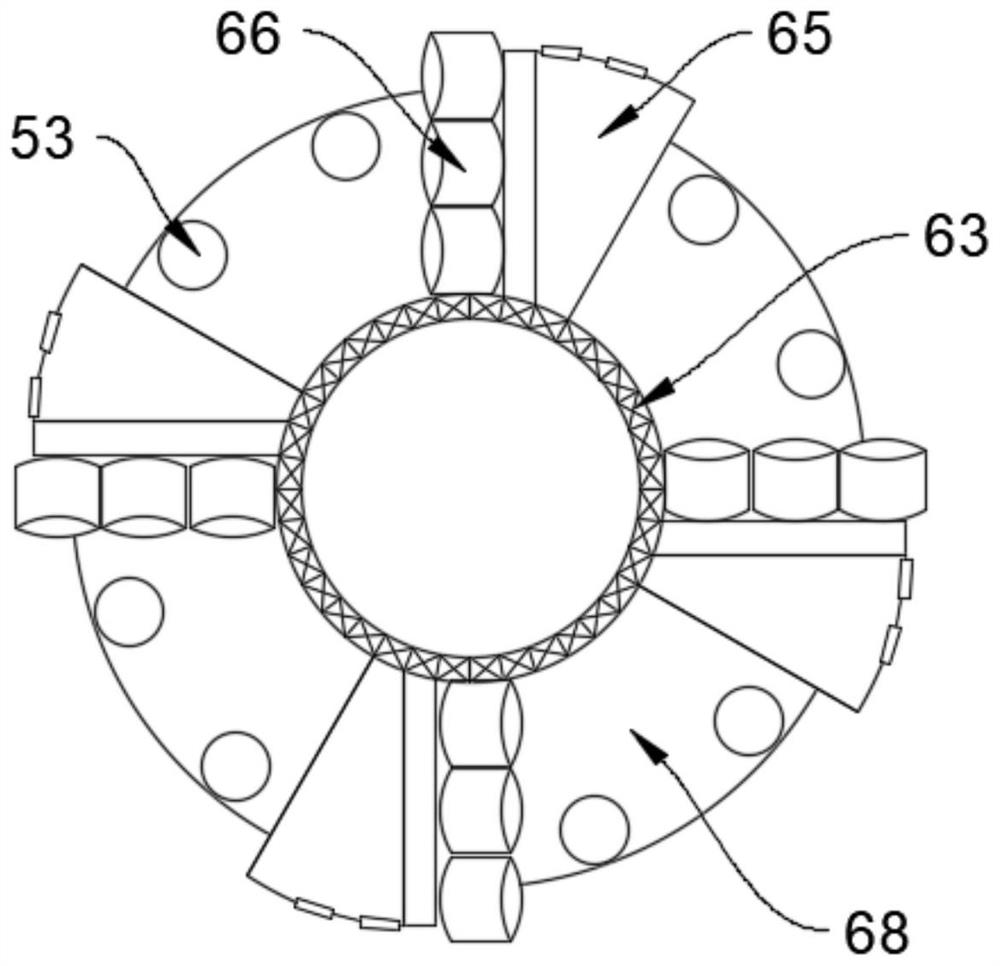

[0026] see Figure 1-7As shown, a low-temperature airtight coal core drilling device and method in a coal mine includes an outer cylinder assembly 1, an inner cylinder assembly 2 is mounted on the inner rotation of the outer cylinder assembly 1, and a collection assembly 3 is fixedly installed on one end of the inner cylinder assembly 2 , one end of the inner cylinder assembly 2 is rotatably installed with a water supply assembly 4, and one end of the inner cylinder assembly 2 is rotatably installed with a cooling assembly 5, one end of the outer cylinder assembly 1 is fixedly installed with a drill assembly 6, and the cooling assembly 5 is respectively connected with the collection assembly 3 communicates with the drill bit assembly 6, and the water supply assembly 4 provides power for the collection assembly 3. The outer cylinder assembly 1 includes an outer cylinder shell 11, and first ball bearings 12 are fixedly installed on both sides of the outer cylinder shell 11. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com