Working electrode for realizing electrochemical test of high-temperature high-pressure water system

A high-temperature and high-pressure water and working electrode technology, which is applied in the direction of electrochemical variables of materials, can solve the problems of high requirements for experimental equipment and working electrode preparation process and difficult implementation, and achieves good sealing performance, simple production, and reduced sealing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

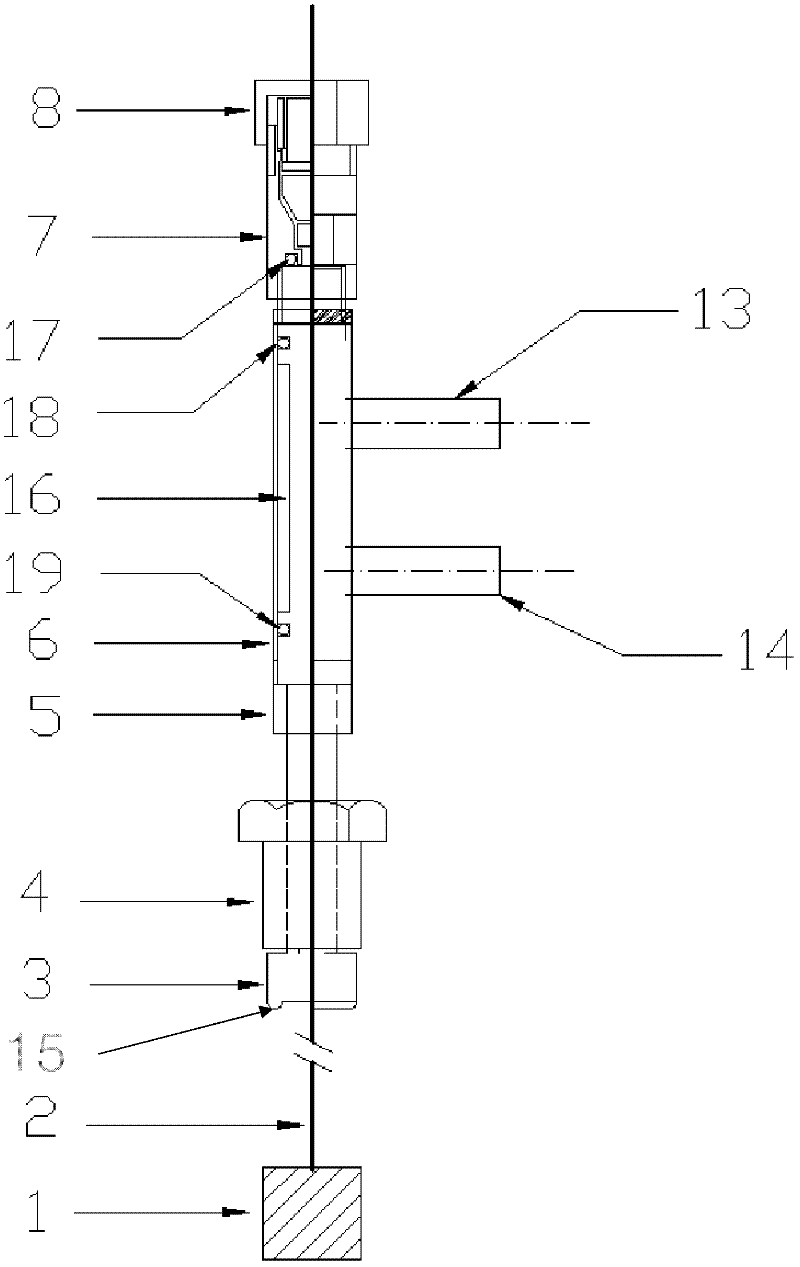

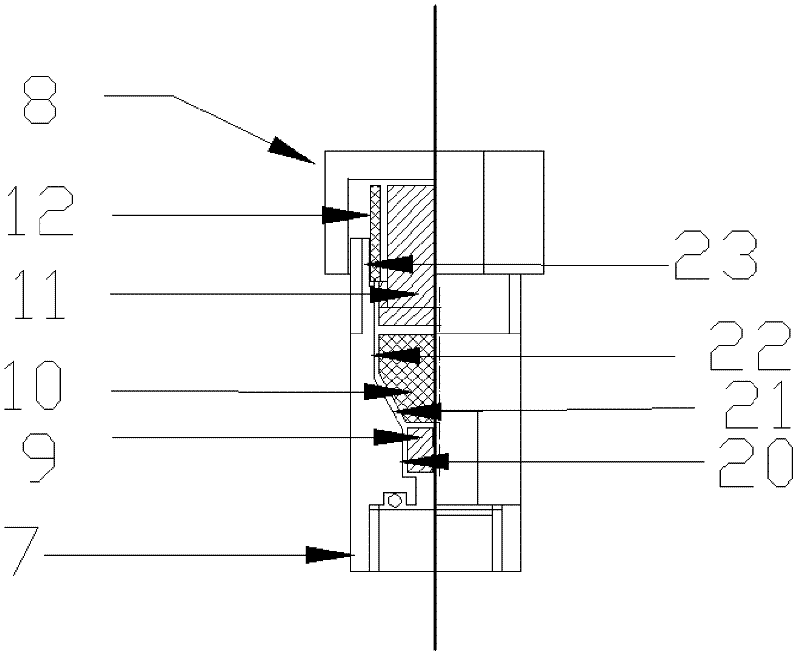

[0024] Such as figure 1 and figure 2 As shown, the present invention provides a working electrode for electrochemical testing of high-temperature and high-pressure water systems. The working electrode is composed of a metal electrode, a high temperature seal, a water cooling device, and a low temperature seal, mainly including: experimental sample 1, electrode wire 2, plug 3, pressure cap 4, support tube 5, cooling tube 6, sealing nut 7 , Compression nut 8, stop plug 9, rubber sealing plug 10, sealing gland 11, fixing bolt 12, etc., the specific structure is as follows:

[0025] The metal electrode includes an experimental sample 1 and an electrode wire 2. The electrode wire 2 is a metal wire, and the outside of the electrode wire 2 is wrapped by a heat shrinkable tube to ensure that the experimental sample 1 is insulated from the autoclave and other electrode metal parts.

[0026] The high-temperature seal includes a plug 3 and a pressure cap 4. The bottom end of the plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com