Electric pile sealing device and method for sealing electric pile

A sealing device and electric stack technology, which is applied in the direction of circuits, fuel cells, electrical components, etc., can solve problems such as poor effect and difficult sealing, and achieve the effects of increasing life, reducing sealing difficulty, and improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

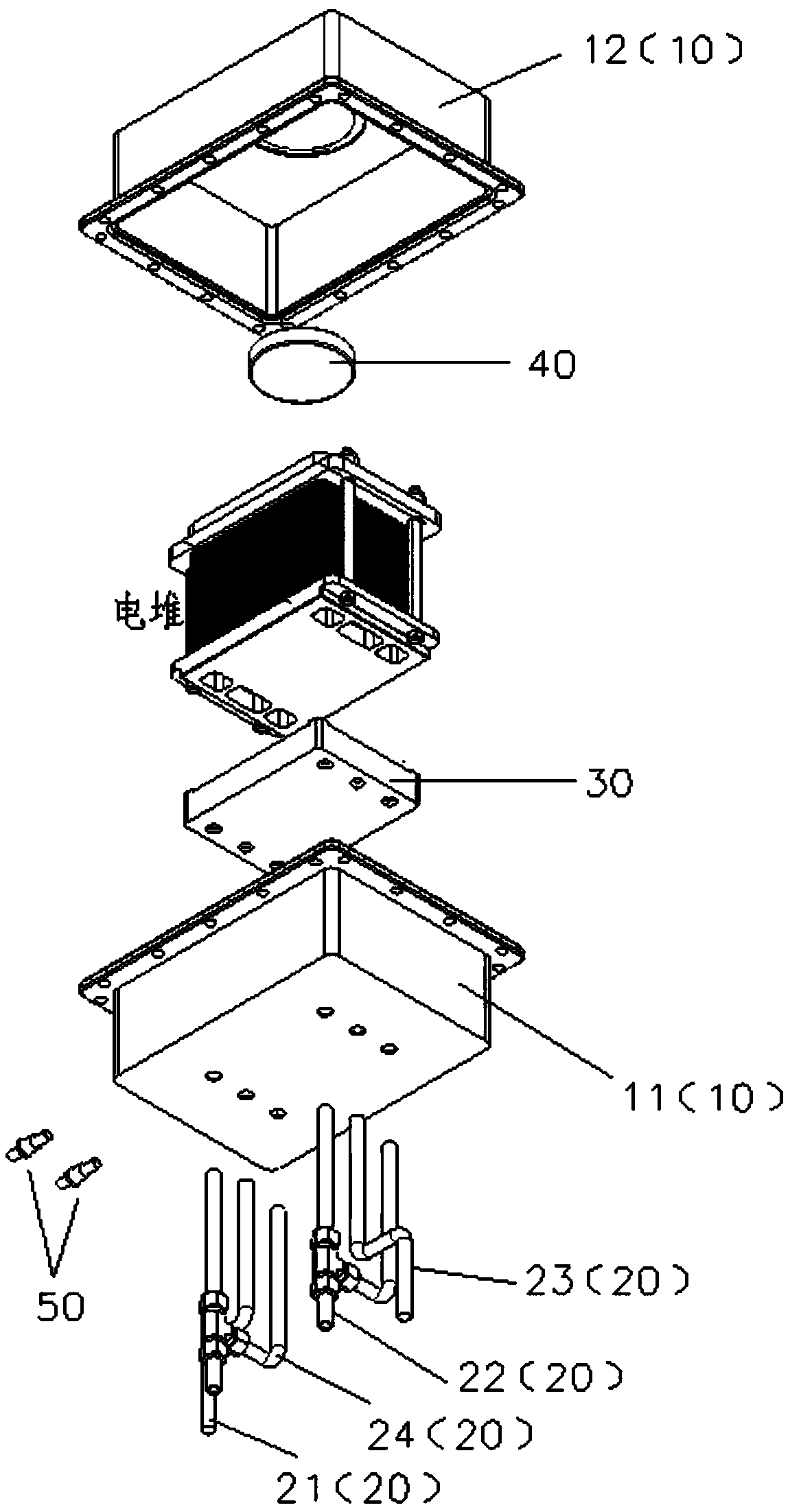

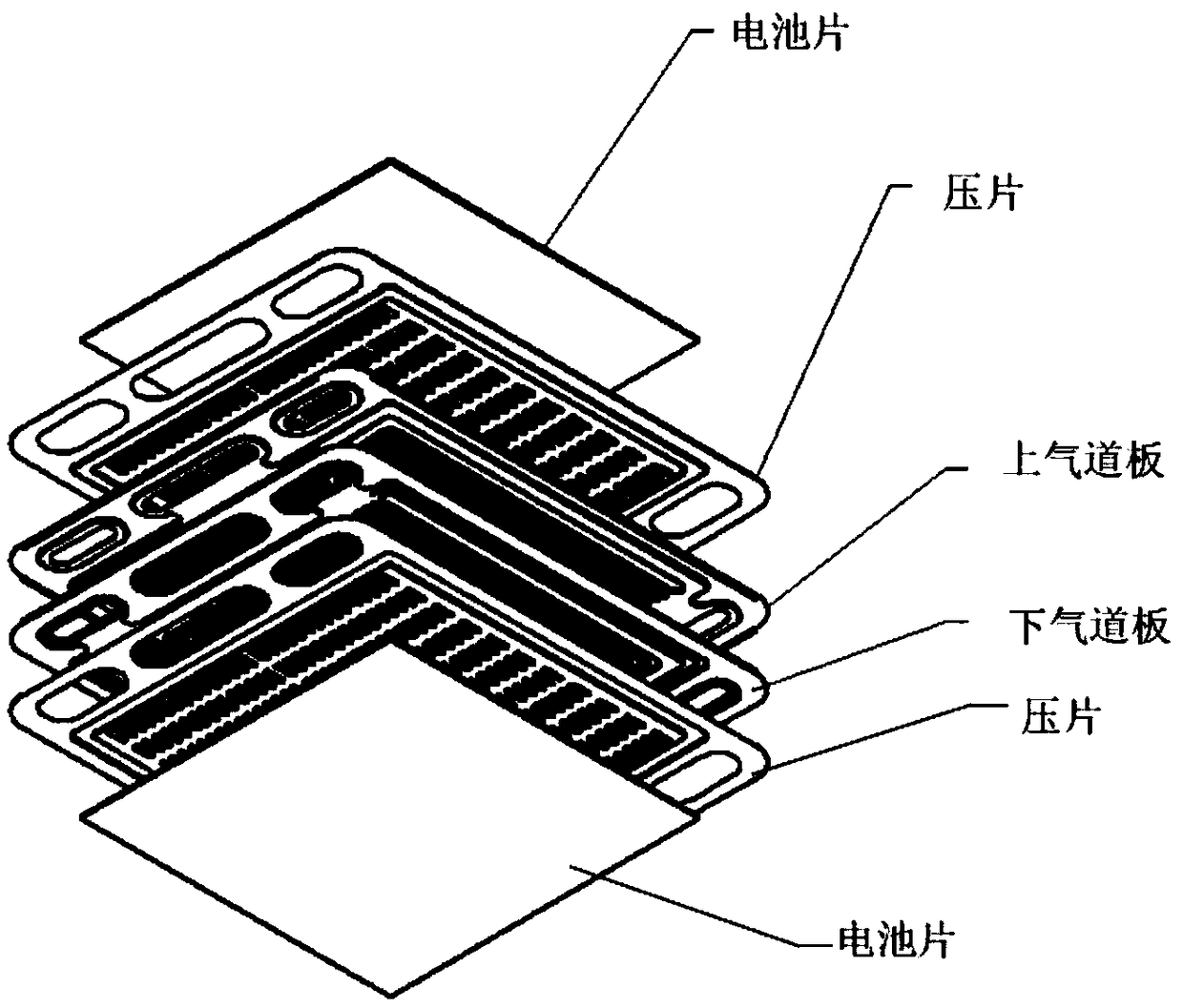

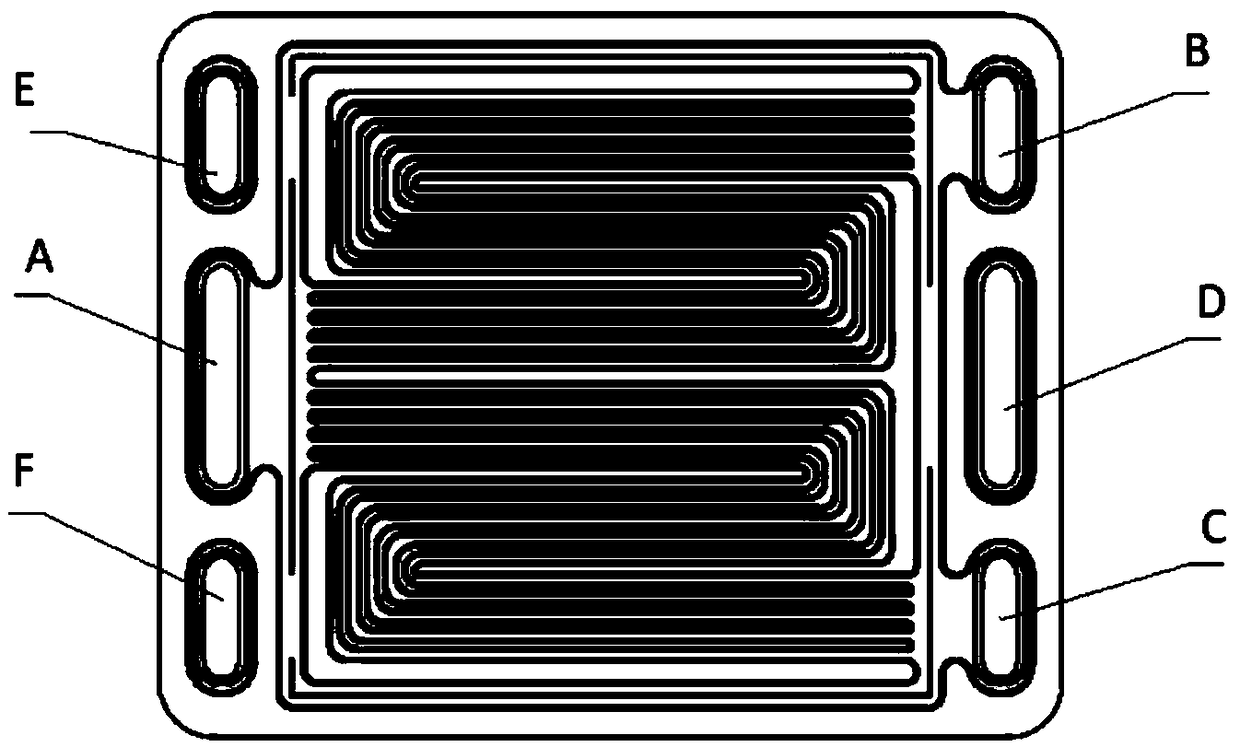

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a stack sealing device, including a sealing box 10 and an air pipe 20, the sealing box 10 includes a lower box 11 and an upper box 12 assembled and installed with each other, the lower box 11 and the The upper boxes 12 are all semi-closed structures, which are combined to form a closed box structure;

[0034] The air pipe 20 is installed on the lower box body 11, one end of the air pipe 20 leaks outside the lower box body 11, and the other end is sealed in the inner cavity of the lower box body 11;

[0035] The bottom of the inner cavity of the lower box 11 is provided with a base 30 for placing a power supply stack, and the positions of the lower box 11 and the base 30 corresponding to the air pipe 20 are provided with through holes for the air pipe 20 to pass through; The side of the lower box 11 is provided with a positive and negative terminal 50;

[0036] The top of the inner cavity of th...

Embodiment 2

[0046] Figure 4 It is a method for sealing an electric stack provided in Embodiment 2 of the present invention. The method is implemented based on the device described in Embodiment 1, and includes the following steps:

[0047] S401. Install the cell stack into the inside of the cell stack sealing device, and feed in cathode gas and anode gas.

[0048] S402. Adjust the gas pressure of the cathode gas and the anode gas, and seal the cell stack, cathode gas and anode gas.

[0049] In order to more clearly demonstrate the implementation process of the solution provided by the embodiment of the present invention, a specific example is given for a detailed introduction.

[0050]First of all, put the stack into the inside of the stack sealing device, pass the high-temperature reaction gas from the anode inlet pipe, the anode gas enters from the bottom plate of the stack, and let the anode gas fill the inside of the sealed box through the opening on the top plate of the stack, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com