Working electrode for achieving electrochemical test in high-temperature and high-pressure water

A technology of high-temperature and high-pressure water and working electrodes, which is applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve the problems of difficult long-term stable test, difficulty, poor sealing effect, etc., achieve accurate and reliable test results, reduce sealing difficulty, increase reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

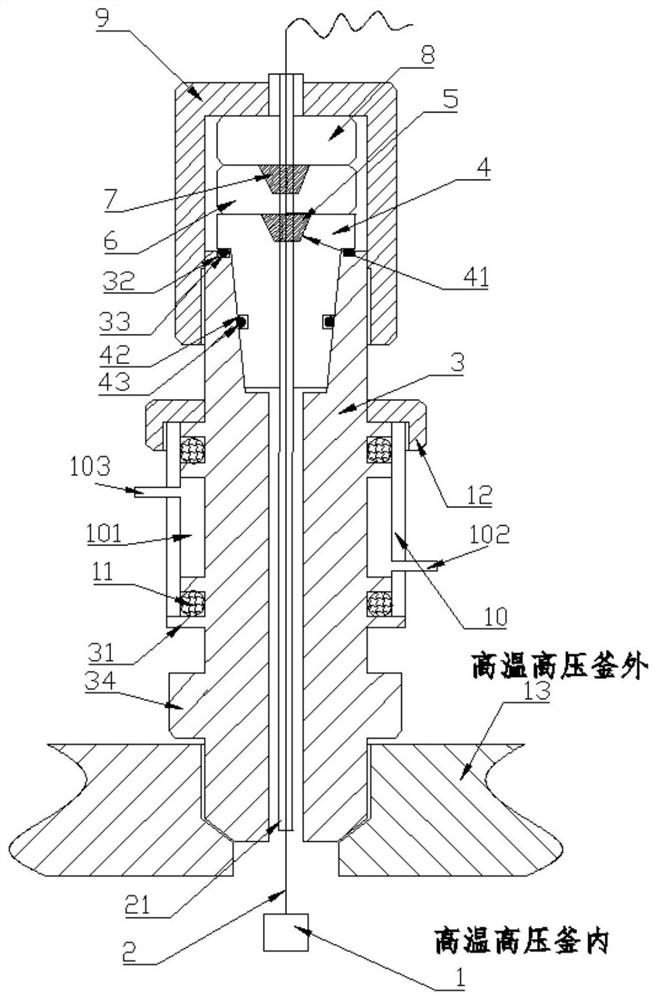

[0021] Such as figure 1 As shown, the present invention provides a working electrode for electrochemical testing in high temperature and high pressure water, including electrode wire 2, body 3, sealing sleeve 4, sealing ring I5, snap ring 6, sealing ring II7, upper end cap 8 and compression Nut 9; wherein, during testing, the sample to be tested 1 is placed in a high-temperature autoclave, one end of the electrode wire 2 is connected to the sample to be tested 1, and the other end passes through the autoclave cover 13 and the body 3 in sequence , the sealing sleeve 4, the snap ring 6, the upper end cap 8 and the compression nut 9 are connected to the electrochemical workstation located inside and outside the high-temperature autoclave, the sealing ring I5 is set between the sealing sleeve 4 and the snap ring 6, and the sealing ring II7 is set on Between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com