High-impact-resistant anti-shearing ethylene propylene diene monomer material

An EPDM rubber and anti-shear technology, which is applied in the field of rubber, can solve the problems of large differences with the comparison documents, and the product's use effect is not as good as it is, and achieve the effects of overcoming poor adhesion, excellent sealing effect, and increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

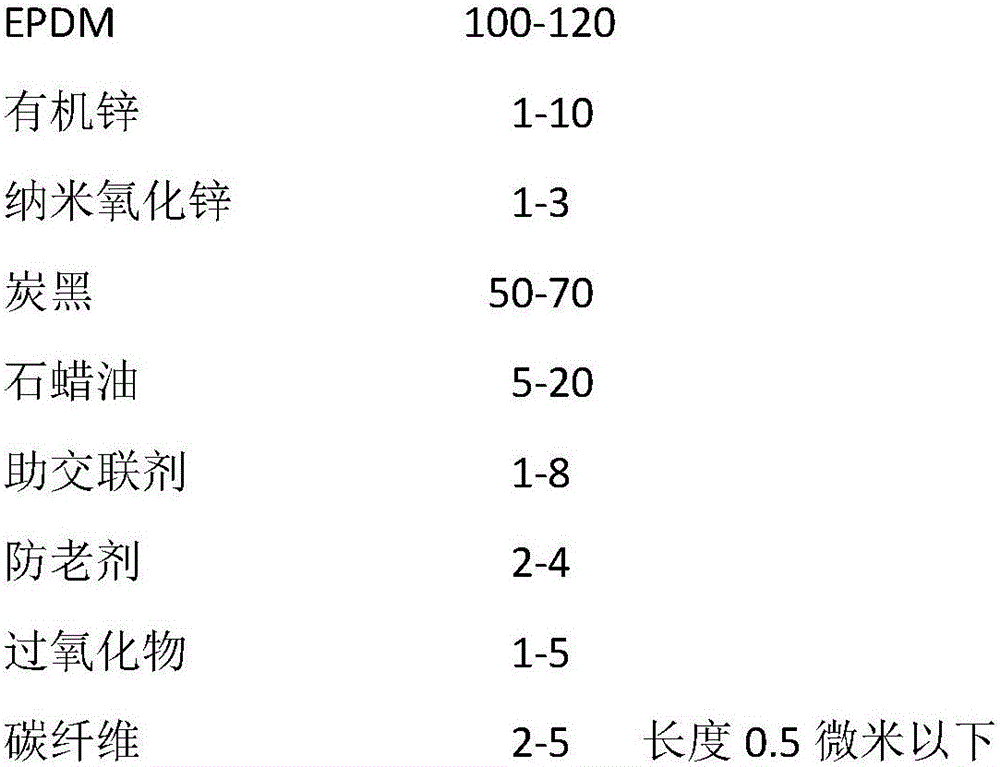

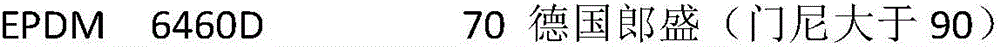

[0031] A high-impact-resistant, shear-resistant EPDM material and a preparation method thereof, the components are as follows: the following are parts by weight

[0032]

[0033]

[0034] Its preparation method of above-mentioned material is as follows:

[0035] ⑴ Plasticize EPDM and EPDM separately, take out materials according to the ratio of raw materials, mix them in the open mill, and start mixing after mixing evenly.

[0036] (2) Mixing is carried out in the internal mixer, the top bolt is pressurized at 0.6 MPa, the maximum temperature is set at 110 degrees, and the feeding sequence: step (1) obtained rubber, organic zinc, nano-zinc oxide, carbon black, paraffin oil, over Oxides, carbon fibers, dispersants, hardeners, additives, knead for 9 minutes, feed into the open mill, and cool to below 60 degrees.

[0037] (3) Put the above-mentioned film into the internal mixer, add cross-linking agent, high-strength adhesive and other remaining original pressure and mix f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com