Performance detecting process of well control product and well head apparatus under low temperature state

A wellhead device, low temperature environment technology, applied in measurement devices, testing of machine/structural components, liquid tightness measurement using liquid/vacuum degree, etc. Use and other problems to achieve the effect of wide use, improve safety, and reduce incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

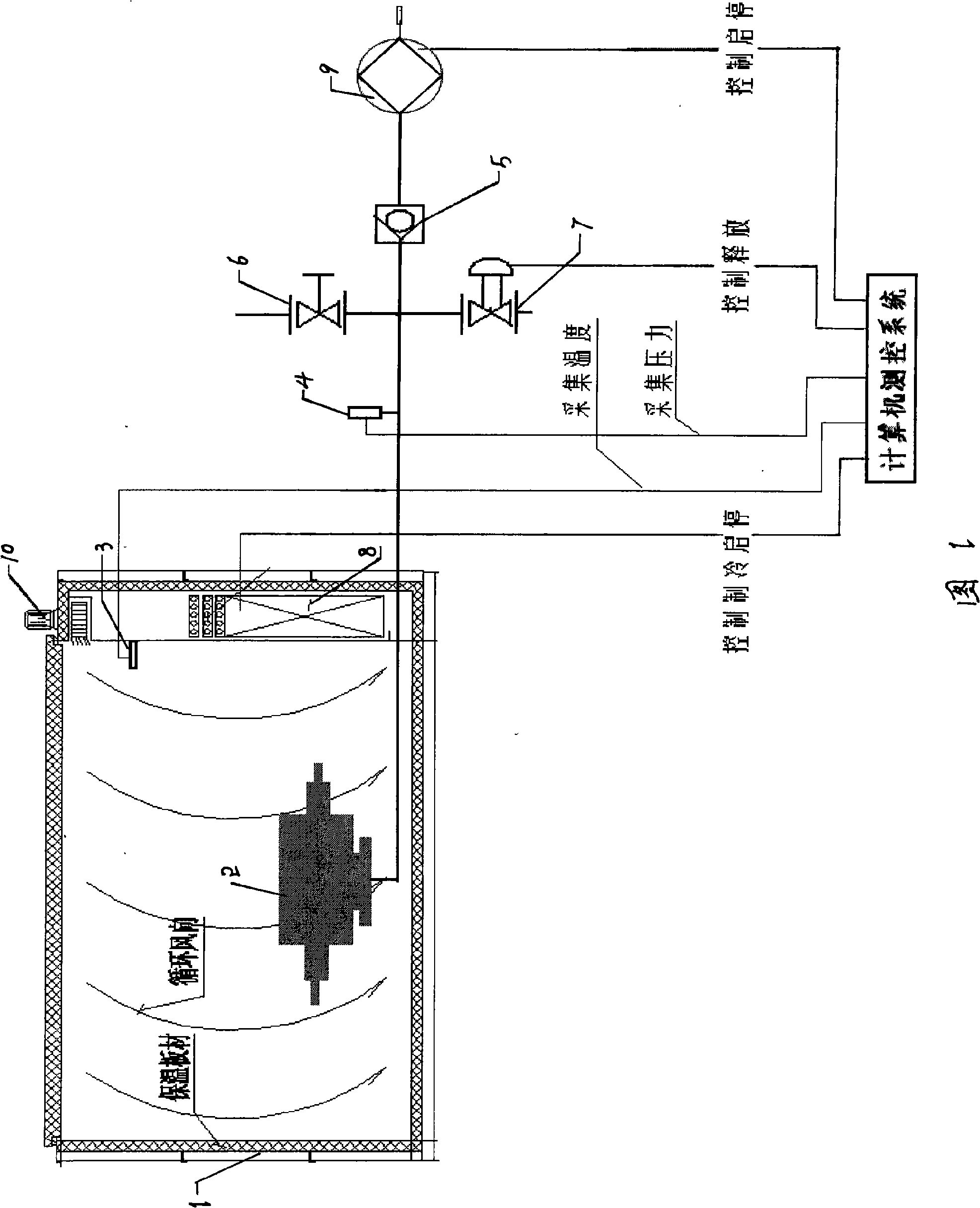

Embodiment 1

[0023] A performance testing process for well control products and wellhead devices in a low-temperature environment, mainly applicable to performance and quality testing of blowout preventers, wellhead devices, valves and other equipment, including a. Setting the tested parts in the low temperature environment of the testing device In the box, connect the tested part with the pressurizing device, and inject the testing medium into the tested part; b. Open the ambient low temperature box, lower the temperature to the rated low temperature -69°C, and keep the temperature at the rated temperature; c. , Turn on the pressurization device, pressurize the tested piece to the rated working pressure of 1MPa; d, stabilize the pressure for 0.5 hours, the computer measurement and control system judges whether the quality and performance of the tested piece are qualified according to the fluctuation value of the temperature and pressure value of the tested piece , compare the collected tem...

Embodiment 2

[0050] A performance testing process for well control products and wellhead devices in a low-temperature environment, mainly applicable to performance and quality testing of blowout preventers, wellhead devices, valves and other equipment, including a. Setting the tested parts in the low temperature environment of the testing device In the box, connect the tested part with the pressurizing device, and inject the testing medium into the tested part; b. Open the ambient low temperature box, lower the temperature to the rated low temperature -29 ℃, and keep the temperature at the rated temperature; c. , Turn on the pressurization device, and pressurize the tested piece to the rated working pressure of 140MPa; d, stabilize the pressure for 2 hours, and the computer measurement and control system judges whether the quality and performance of the tested piece are qualified according to the fluctuation value of the temperature and pressure value of the tested piece , compare the colle...

Embodiment 3

[0052] A performance testing process for well control products and wellhead devices in a low-temperature environment, mainly applicable to performance and quality testing of blowout preventers, wellhead devices, valves and other equipment, including a. Setting the tested parts in the low temperature environment of the testing device In the box, connect the tested part with the pressurizing device, and inject the testing medium into the tested part; b. Open the ambient low temperature box, reduce the temperature to the rated low temperature -40 ℃, and keep the temperature at the rated temperature; c. , Turn on the pressurization device, pressurize the tested part to the rated working pressure of 70MPa; d, stabilize the pressure for 1.5 hours, the computer measurement and control system judges whether the quality and performance of the tested part are qualified according to the fluctuation value of the temperature and pressure value of the tested part , compare the collected temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com