Efficient manufacturing method of insulated container and manufactured insulated container

A technology for a thermal insulation container and a manufacturing method, which is applied to thermal insulation containers, containers, household refrigeration devices, etc., can solve the problem of poor fusion and adhesion between glass glue and the main body of the container, the vacuum insulation container is not insulated, and the glass glue is easy to fall. and other problems, to achieve the effect of easy processing, ensuring thermal insulation effect and good fusion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0029] The efficient method for manufacturing an insulated container of the present embodiment comprises the following steps:

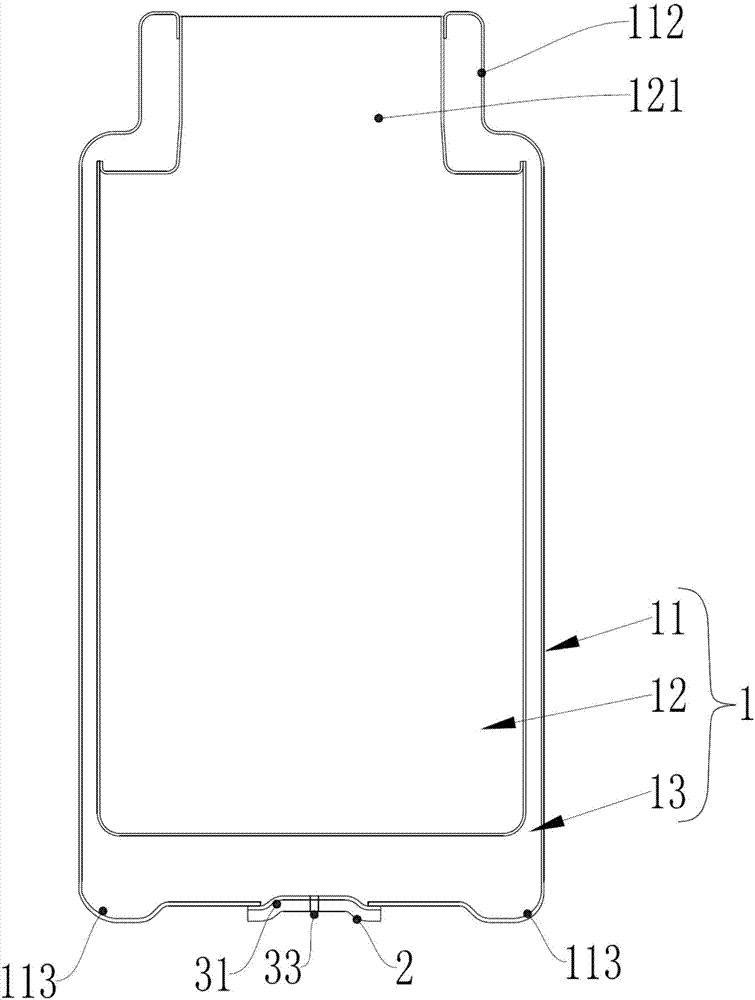

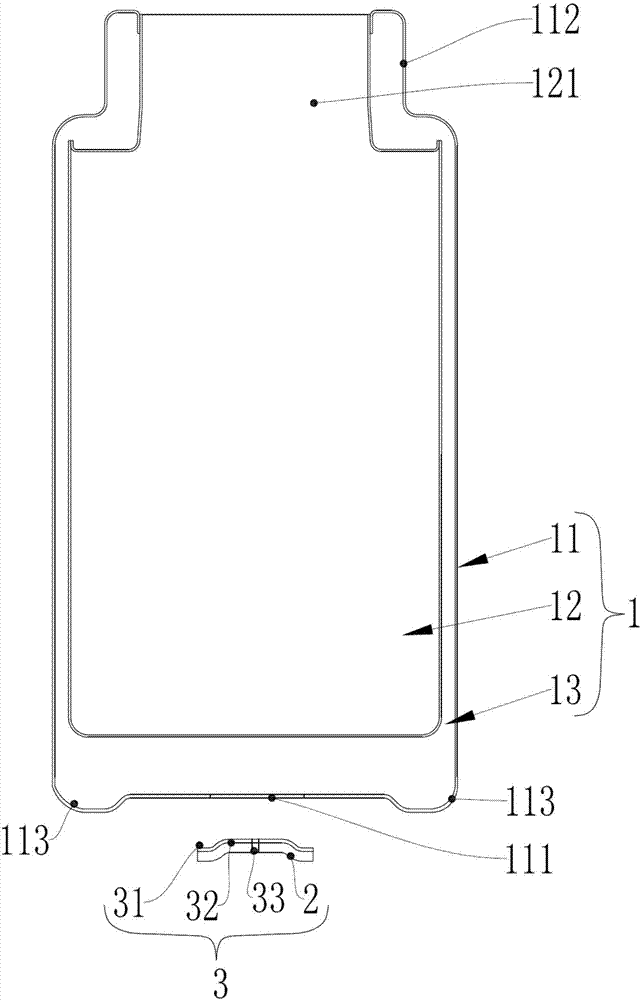

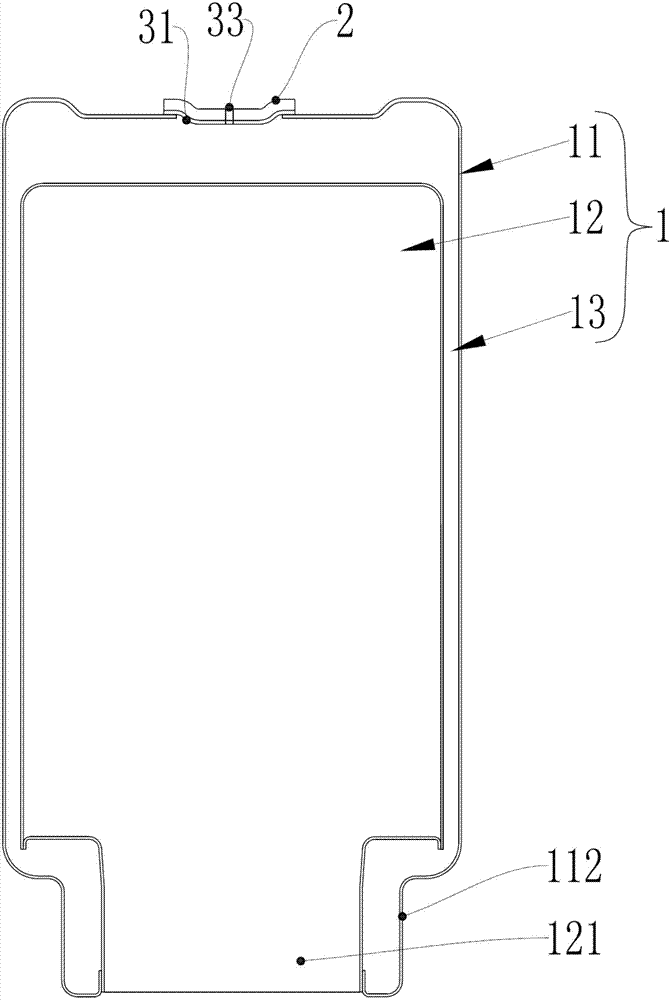

[0030] Step A, such as figure 1 , figure 2 As shown, the inner shell 12 is installed in the outer shell 11 to form the container main body 1, and the container main body 1 forms a thermal insulation cavity 13 between the outer shell 11 and the inner shell 12; meanwhile, the low-temperature sealing layer 2 and the substrate layer 31 welded to each other to form a sealing sheet 3;

[0031] Step B, such as figure 2 As shown, an exhaust groove 32 is provided on the sealing sheet 3, and an exhaust hole 33 is provided on the exhaust groove 32; at the same time, an installation hole 111 is provided on the bottom of the housing 11;

[0032] Step C, such as figure 1 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com