Ethylene-propylene-diene monomer (EPDM) material for super high and low temperature resistant sealing element and preparation method of EPDM material

A technology of EPDM rubber and seals, which is applied in the field of rubber, can solve the problems of large differences from comparison documents and poor product use effects, and achieve the effects of optimized physical properties and excellent sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

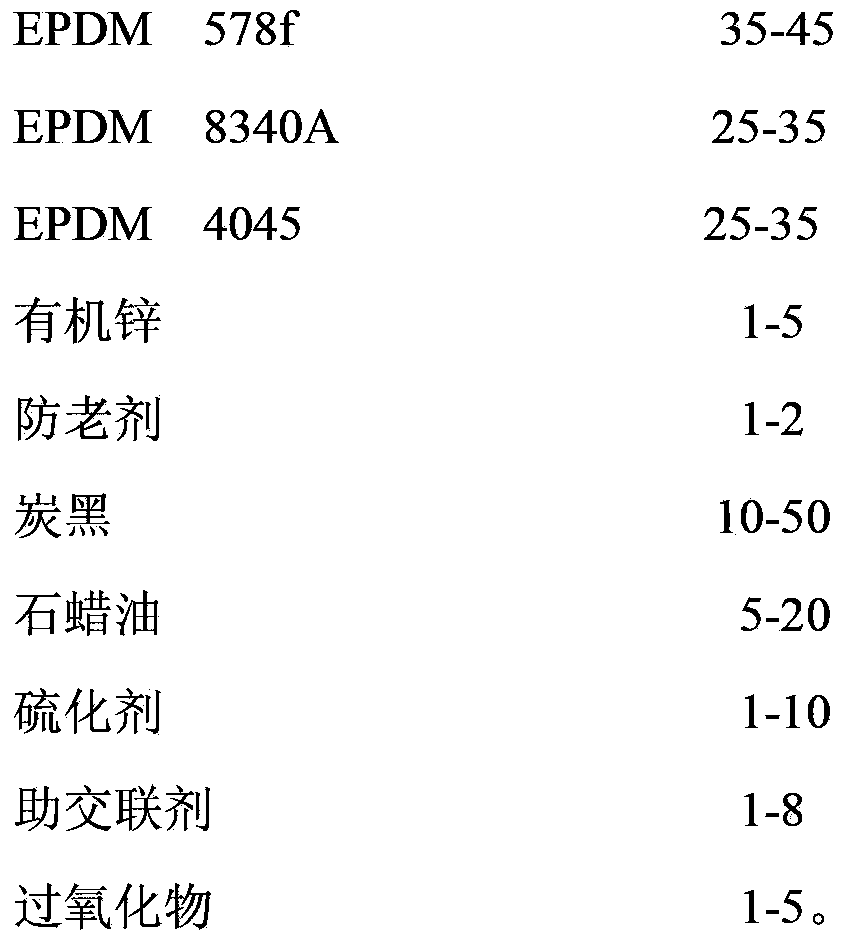

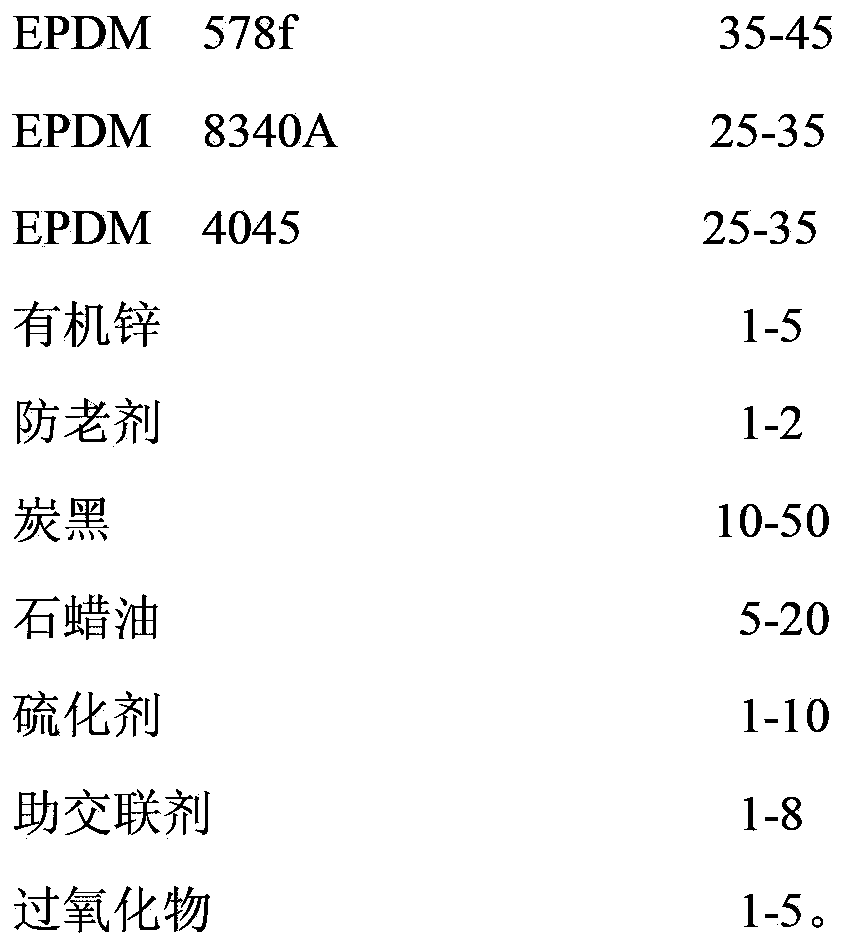

[0028] A kind of EPDM rubber material for super high and low temperature resistant seals, its composition and parts by weight are as follows:

[0029]

[0030]

[0031] The preparation method of above-mentioned sizing material is as follows:

[0032] ⑴ Each type of ethylene-propylene rubber (EPDM 578f, EPDM 8340A, EPDM 4045) is masticated separately, and the materials are taken according to the ratio of raw materials, mixed in the open mill, and mixed evenly before mixing;

[0033] (2) Mixing is carried out in the internal mixer, the top bolt is pressurized at 0.6 MPa, and the maximum temperature is set at 110 degrees. The order of feeding: ethylene propylene rubber, carbon black, paraffin oil, organic zinc (zinc methacrylate), anti-aging agent , knead for 9 minutes, open the mill to discharge the sheet, and cool to below 60 degrees;

[0034] (3) Put the above-mentioned film into the internal mixer, add vulcanizing agent, auxiliary cross-linking agent, peroxide (dicumyl...

Embodiment 2

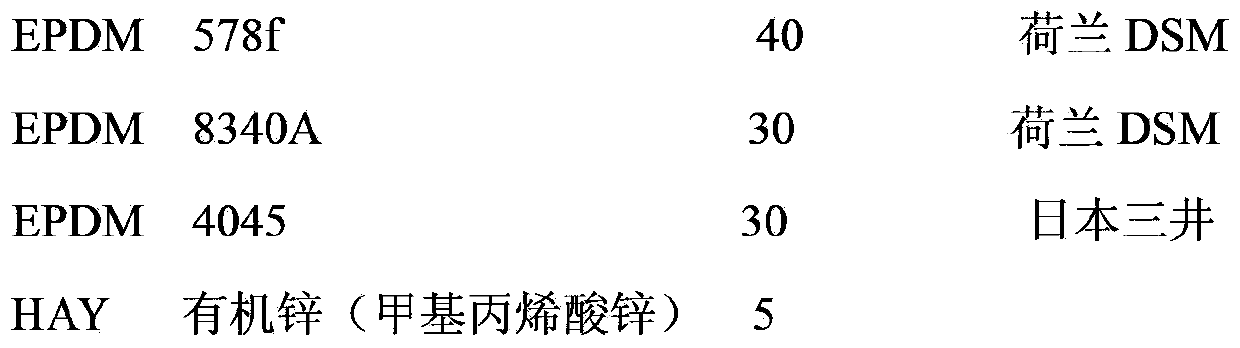

[0038] A kind of EPDM rubber material for super high and low temperature resistant seals, its composition and parts by weight are as follows:

[0039]

[0040]

[0041] Preparation method is with embodiment 1.

[0042] It has been proved by experiments that the present invention can improve and optimize its characteristics by using different compounding techniques and special additives, and the obtained ethylene-propylene rubber can be used for a long time in the range of -50 to 150 degrees, and the sealing products made of this rubber can be used at -50 It can maintain excellent sealing effect in the environment of 150 degrees. After repeated tests, multi-model coordination, reasonable proportions, and optimization of process performance and physical properties, all indicators of the test results exceeded German standards.

[0043] The sizing material of the invention expands the adaptable temperature range of EPDM -60°C to 170°C, and its application can be used for no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com