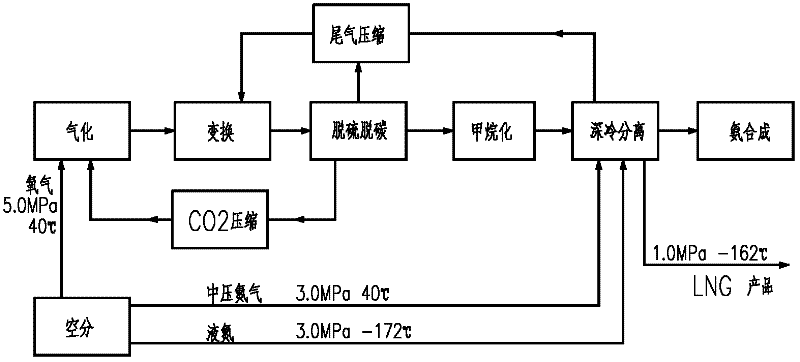

Process for coproducing liquefied natural gas (LNG) and synthetic ammonia

A technology for liquefied natural gas and synthetic ammonia, applied in the field of coal chemical industry, can solve the problems of not obtaining liquefied natural gas and low utilization rate of hydrogen treatment, and achieve the effect of saving energy and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

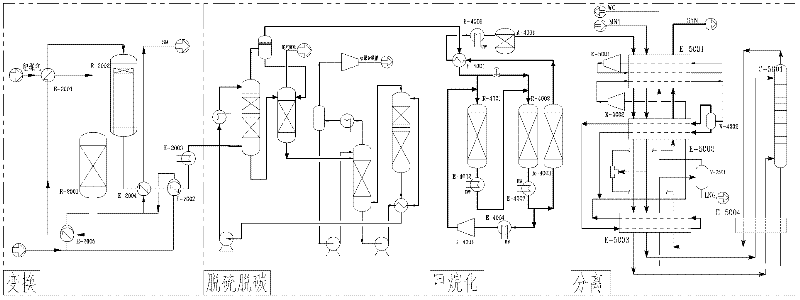

[0063] Reference attached figure 1 and 2 , the high-temperature crude gas produced by pressurized gasification of coal powder as raw material, adjust the conversion rate of CO conversion unit according to the output of downstream products to synthetic ammonia and liquid methane, for 12000Nm 3 / h natural gas and 500 tons / day synthetic ammonia cogeneration unit can be realized by two-stage wide temperature and sulfur resistance conversion. The loading amount and loading scheme of the conversion catalyst can be adjusted accordingly according to the product scheme.

[0064] The crude gas from gasification passes through the heat exchanger (E-2001) after the steam is produced by the waste heat boiler (E-2005) at the outlet of the first-stage converter, and then it is divided into 40-60% (it can be adjusted according to the production ratio) The crude gas enters the first-stage shift furnace (R-2001), and the CO is converted to 20-40% (v / v). After heat exchange with the crude gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com