Method for extracting hydrogen and methane from coke oven gas by utilizing membrane separation and low-temperature rectification

A technology of coke oven gas and low temperature rectification, which is applied in hydrogen separation, fractional condensation purification/separation, organic chemistry, etc., can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

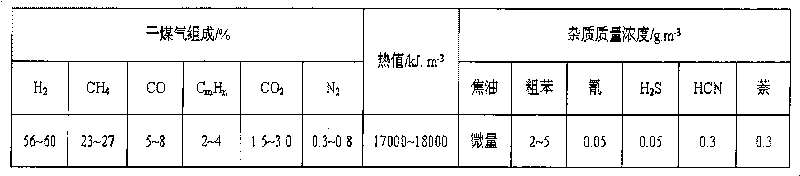

[0042] Compress the coke oven gas collected from coke production with a hydrogen content of 56% and a methane content of 26% to 0.12MPa and cool it to 40°C, and then undergo rough desulfurization and pretreatment to remove sulfur, benzene, naphthalene and tar Impurities;

[0043] After crude desulfurization and pretreatment, the coke oven gas is compressed to 2.2MPa and hydrolyzed to remove H at 130°C 2 S;

[0044] Hydrolyzed coke oven gas is used to remove CO by N-methyldiethanolamine wet method 2 , so that CO in coke oven gas 2 content down to trace amounts;

[0045] CO removal by N-methyldiethanolamine wet method 2 The coke oven gas adopts the method of adsorption to remove sulfide, mercury, moisture and high-carbon compounds above C5;

[0046] After the above steps, the coke oven gas with a temperature of 50°C and a pressure of 2.2MPa enters the membrane separation device. The polymer film in the membrane separation device is a polyimide membrane, which can also be a ...

Embodiment 2

[0060] Compress the coke oven gas collected from coke production with a hydrogen content of 61% and a methane content of 23% to 0.13MPa and cool it to 30°C, and then undergo rough desulfurization and pretreatment to remove sulfur, benzene, naphthalene and tar Impurities;

[0061] After crude desulfurization and pretreatment, the coke oven gas is compressed to 3.0MPa and hydrolyzed to remove H at 300°C 2 S;

[0062] Hydrolyzed coke oven gas is used to remove CO by N-methyldiethanolamine wet method 2 , so that CO in coke oven gas 2 content down to trace amounts;

[0063] CO removal by N-methyldiethanolamine wet method 2 The coke oven gas adopts the method of adsorption to remove sulfide, mercury, moisture and high-carbon compounds above C5;

[0064] After the above steps, the coke oven gas with a temperature of 50°C and a pressure of 2.7MPa enters the membrane separation device. The polymer film in the membrane separation device is a polysulfone membrane, or a polyimide mem...

Embodiment 3

[0078] Compress the coke oven gas collected from coke production with a hydrogen content of 61% and a methane content of 23% to 0.15MPa and cool it to 20°C, and then undergo rough desulfurization and pretreatment to remove sulfur, benzene, naphthalene and tar Impurities;

[0079] After crude desulfurization and pretreatment, the coke oven gas is compressed to 4.0MPa and hydrolyzed to remove H at 430°C 2 S;

[0080] Hydrolyzed coke oven gas is used to remove CO by N-methyldiethanolamine wet method 2 , so that CO in coke oven gas 2 content down to trace amounts;

[0081] CO removal by N-methyldiethanolamine wet method 2 The coke oven gas adopts the method of adsorption to remove sulfide, mercury, moisture and high-carbon compounds above C5;

[0082] After the above steps, the coke oven gas with a temperature of 50°C and a pressure of 2.7MPa enters the membrane separation device. The polymer film in the membrane separation device is a polysulfone membrane, or a polyimide mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com