System and method for preparing high purity carbon monoxide and hydrogen-enriched co-production liquid methane

A carbon monoxide and liquid methane technology, which is applied in refrigeration and liquefaction, liquefaction, lighting and heating equipment, etc., can solve the problems that the value of methane is not reasonably utilized, the rational use of methane is not proposed, and the process is complicated, so as to achieve low investment and reduce impurities. requirements, the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

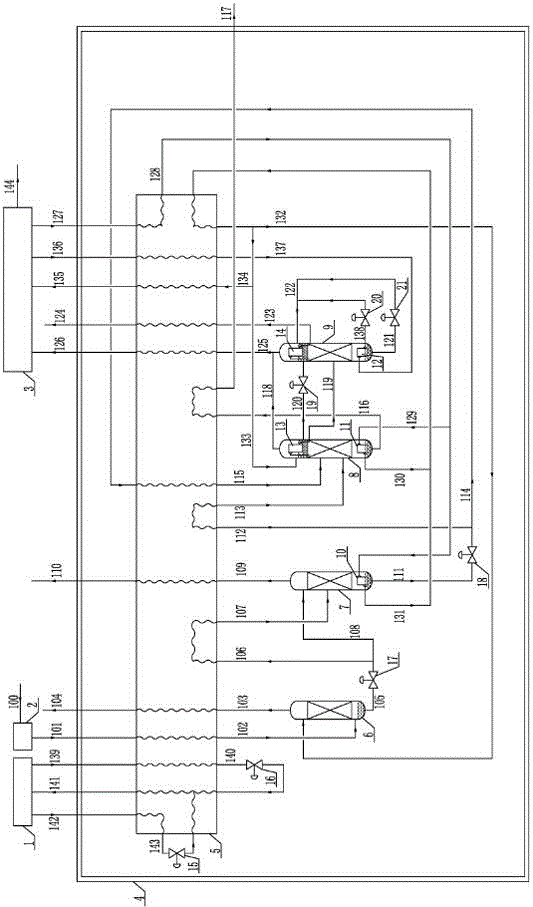

[0023] like figure 1 As shown, a system for producing high-purity carbon monoxide and hydrogen-rich gas for co-production of liquid methane mainly includes a feed gas purification unit 2, a low-temperature liquefaction separation unit 4, a CO product compressor 3, and a mixed refrigerant compressor 1; The low-temperature liquefaction separation unit includes a main heat exchanger 5, a methane washing tower 6, a dehydrogenation tower 7, a demethanization tower 8, and a denitrogenation tower 9, and a first evaporator 10 is provided at the bottom of the dehydrogenation tower. The bottom of the demethanizer is provided with a second evaporator 11, the top of the tower is provided with a first condenser 13, the bottom of the denitrification tower is provided with a third evaporator 12, and the top of the tower is provided with a second condenser 14 The inlet of the purification unit 2 is communicated with the first pipeline 100, and the outlet of the purification unit is communicat...

Embodiment 2

[0028] A method for producing high-purity carbon monoxide and hydrogen-rich gas to co-produce liquid methane. The raw material gas with a volume content of 0.5%~10% of methane and a volume content of nitrogen of 4%~8% passes through the first pipeline at a pressure of 3.0MPa~6.0MPa. After entering the purification unit, the trace amount of CO in the raw gas is absorbed by the adsorbent in the purification unit 2and water are removed, and the raw material gas after removing impurities enters the main heat exchanger through the second pipeline and is cooled to ~100K. After cooling, it enters the methane washing tower through the third pipeline to wash the methane in the raw material. The hydrogen-rich gas with a hydrogen volume content of more than 77% is obtained from the outlet of the gas phase at the top of the tower. The hydrogen-rich gas enters the main heat exchanger through the fourth pipeline to recover the cooling capacity and is reheated. After reheating, the hydrogen-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com